Temperature measurement system and method based on fiber grating sensing

A temperature measurement and fiber grating technology, applied in the field of optical fiber temperature measurement systems, can solve the problems of inaccurate measurement and the inability of the system to better adapt to a wide range of industrial control site environments.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0081] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings. It should be understood that the preferred embodiments are only for illustrating the present invention, but not for limiting the protection scope of the present invention.

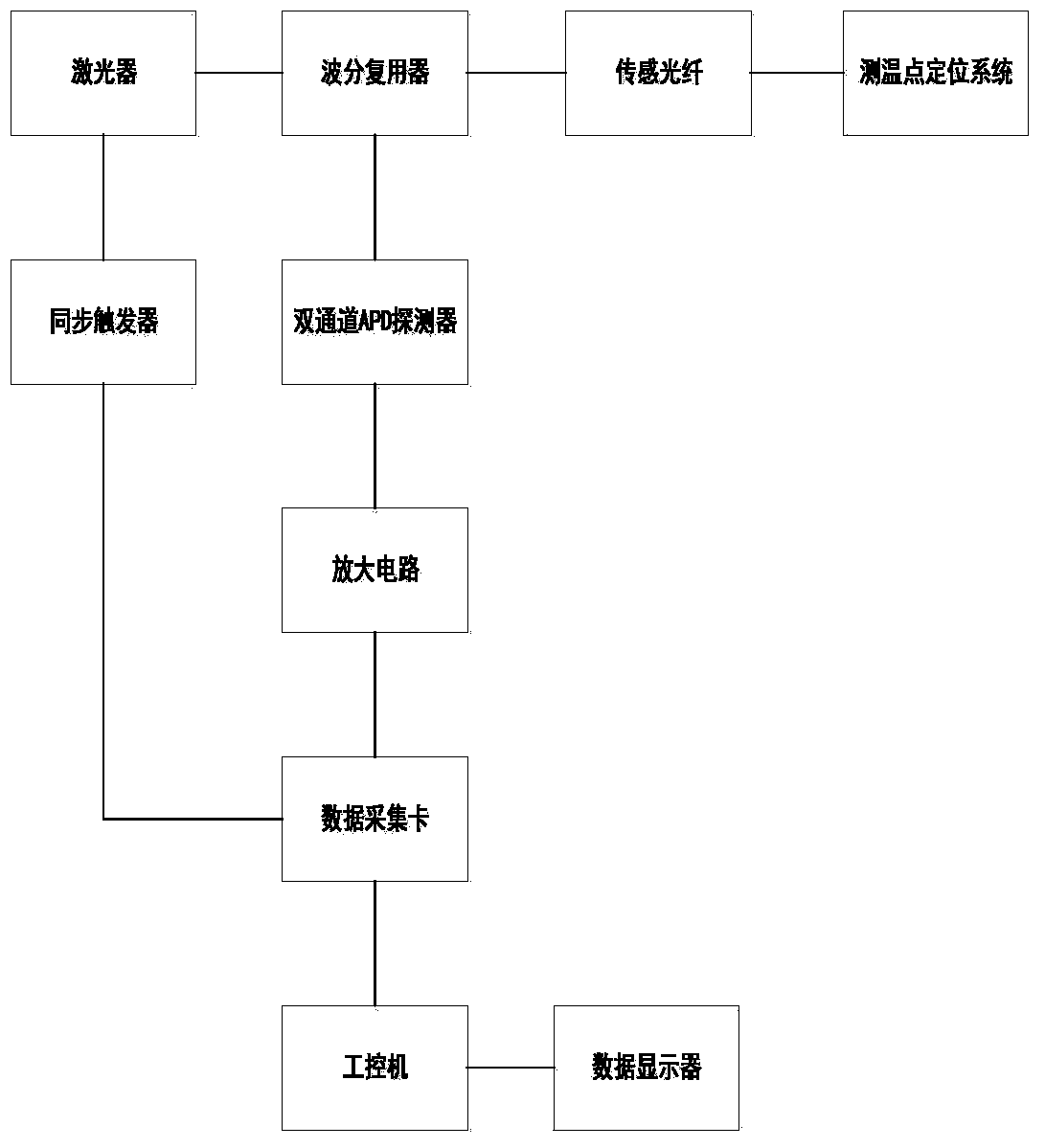

[0082] figure 1 The temperature measurement system based on fiber Bragg grating sensing provided by the embodiment of the present invention is shown in the figure: a temperature measurement system based on fiber Bragg grating sensing provided by the present invention includes a laser, a temperature measurement point positioning system, and a synchronous trigger Device, wavelength division multiplexer, dual-channel APD detector, amplifier circuit, data acquisition card, industrial computer and data display;

[0083] The laser emits a pulsed optical signal, and at the same time sends a synchronous signal through a synchronous trigger to drive the data acquisition card t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com