Simulation measuring and control platform for porous material steam ironing technique study

A technical research, porous material technology, applied in the field of engineering measurement and control, can solve the problems of discontinuous accuracy, incompleteness, and unsatisfactory steam ironing effect, and achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the present invention more comprehensible, preferred embodiments are described in detail below with accompanying drawings.

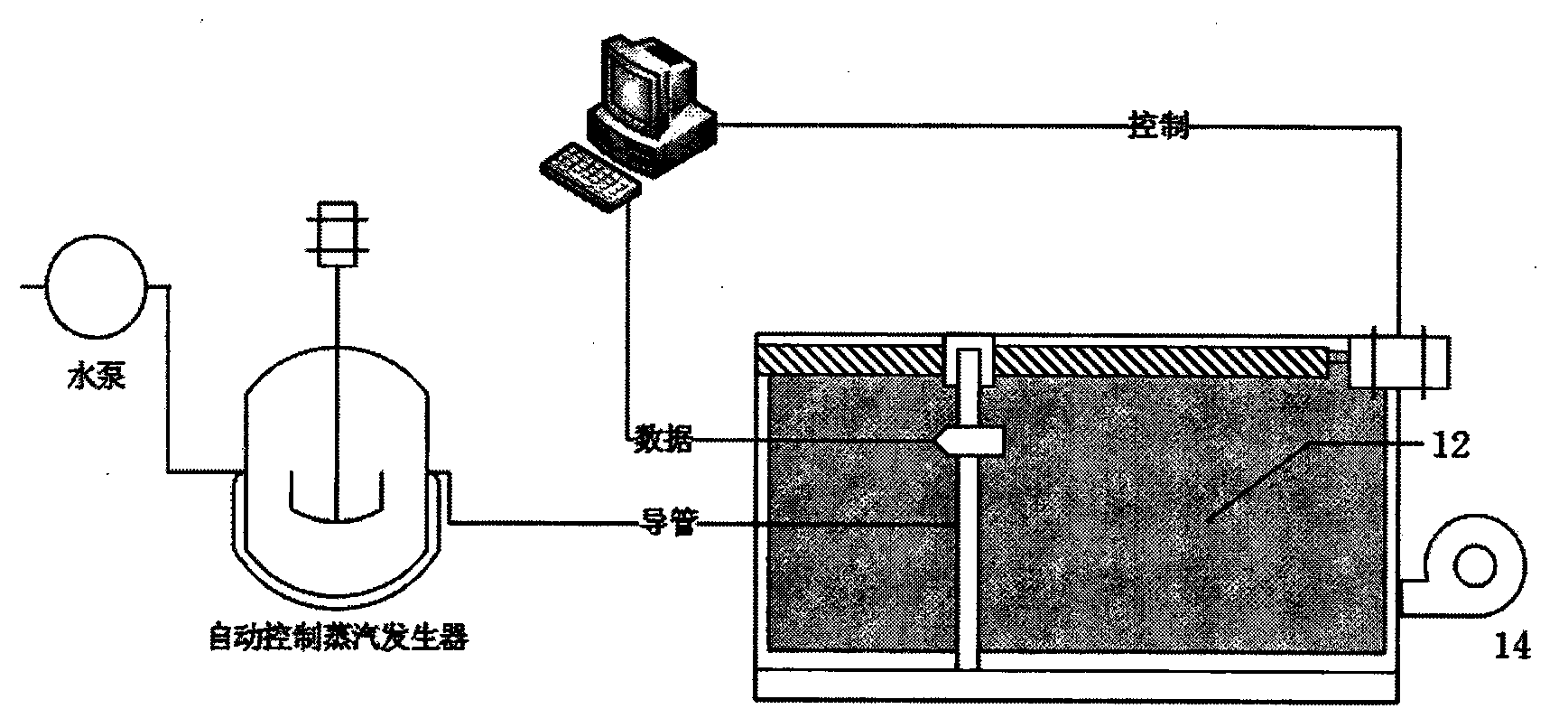

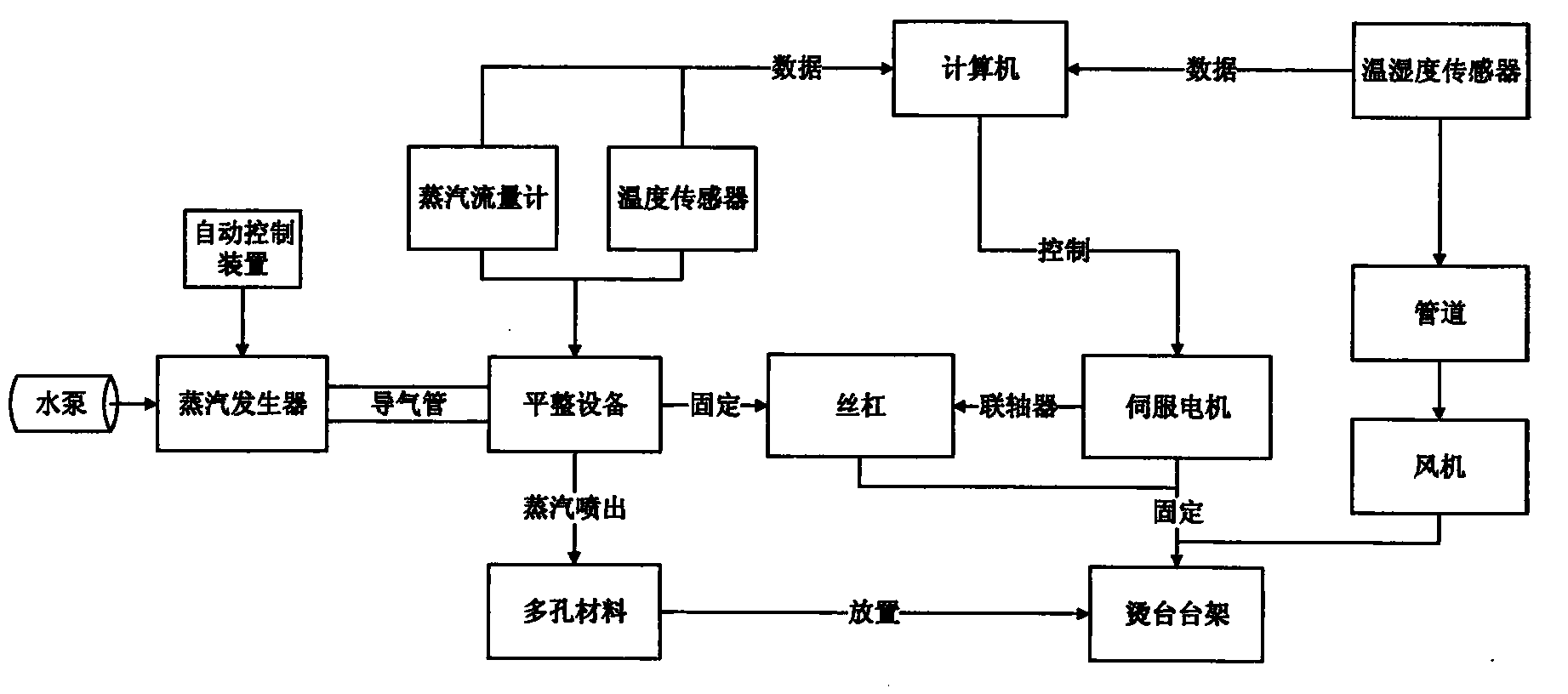

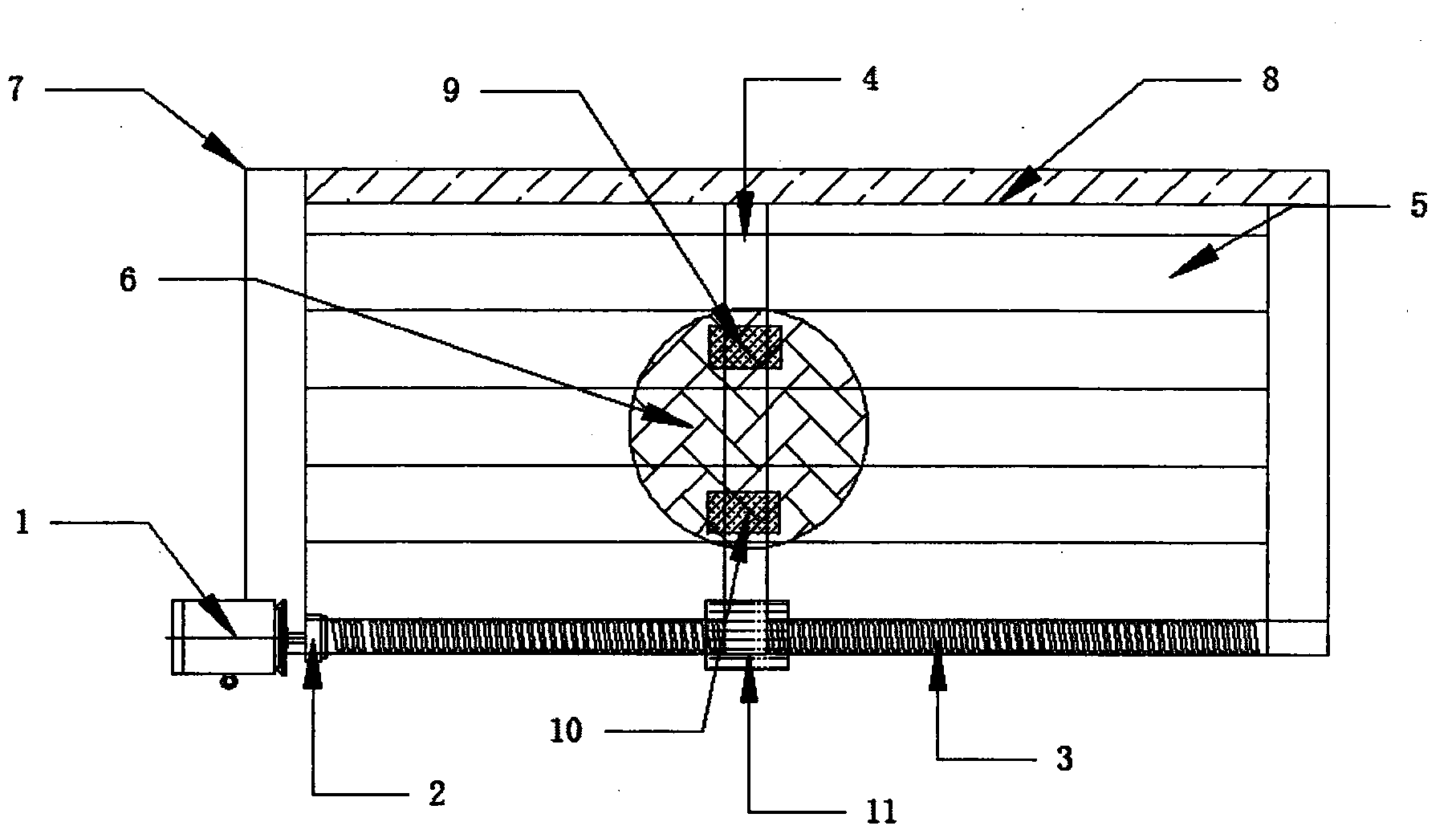

[0024] combine figure 1 and figure 2 , the present invention provides a simulation measurement and control platform for the research of porous material steam ironing technology, including feed water pump, steam generating device with automatic control device, steam air duct, ironing equipment, mobile control device, steam temperature sensor 9. Steam flow meter 10, ironing stand and fan cooling system, pressure sensor 6.

[0025] The steam generating device has a feed water pump to feed water. The steam generating device is used to generate steam, the steam volume of the steam can be adjusted steplessly through the automatic control device, and the pressure and temperature of the steam can be controlled. The steam generating device includes a safety valve, a steam pressure controller, and a steam automatic control device compos...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap