Die-cutting machine electric cabinet test device

A technology for testing devices and electromechanical cabinets, which is applied in the direction of measuring devices, measuring electricity, and measuring electrical variables, etc. It can solve problems such as inability to completely test the wiring of the electric cabinet, the inability to control the contact action of the contactor, and the inability to control the circuit board of the electric cabinet. , to achieve the effect of easy to fix errors, improve assembly quality, and save man-hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

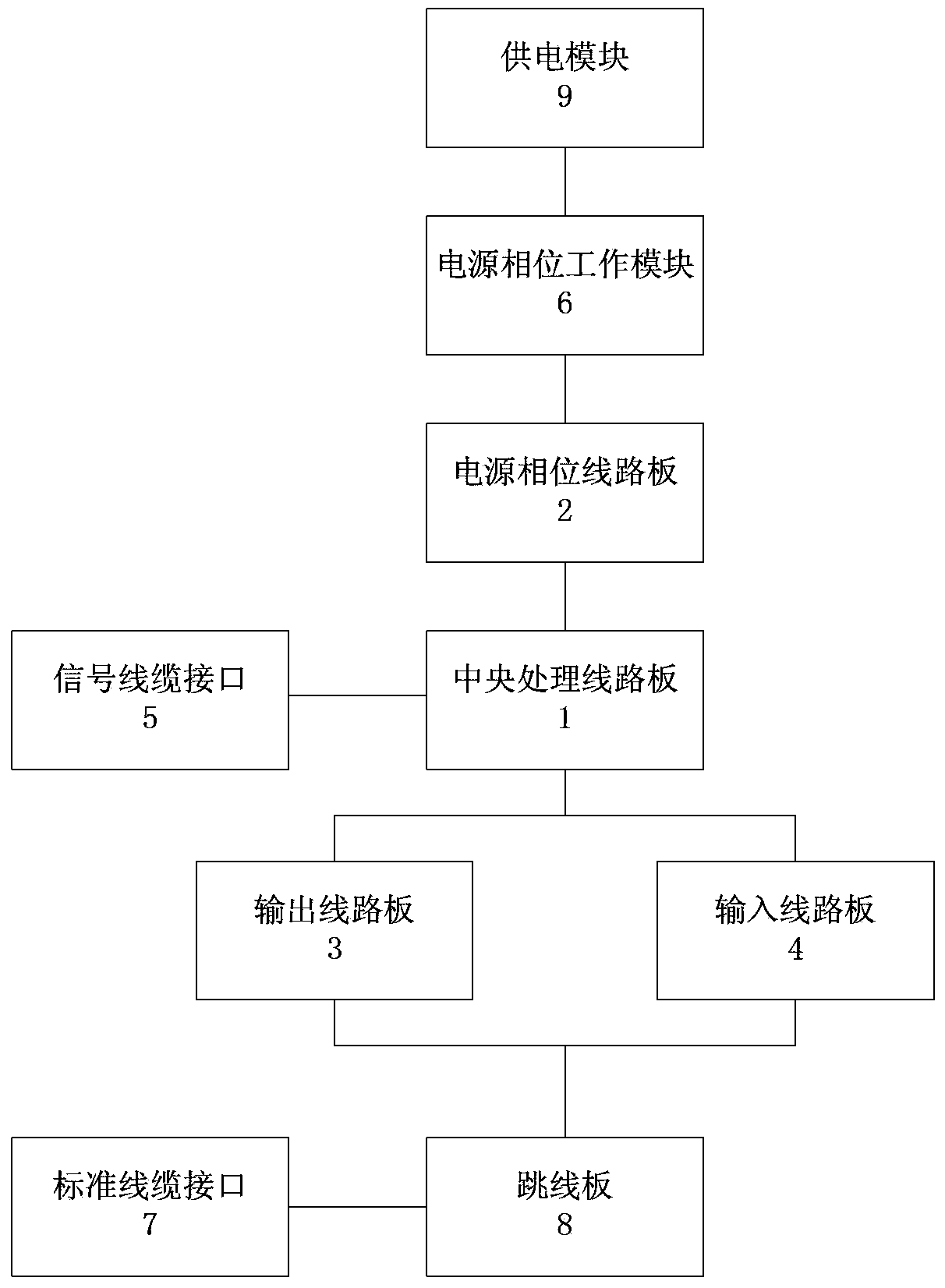

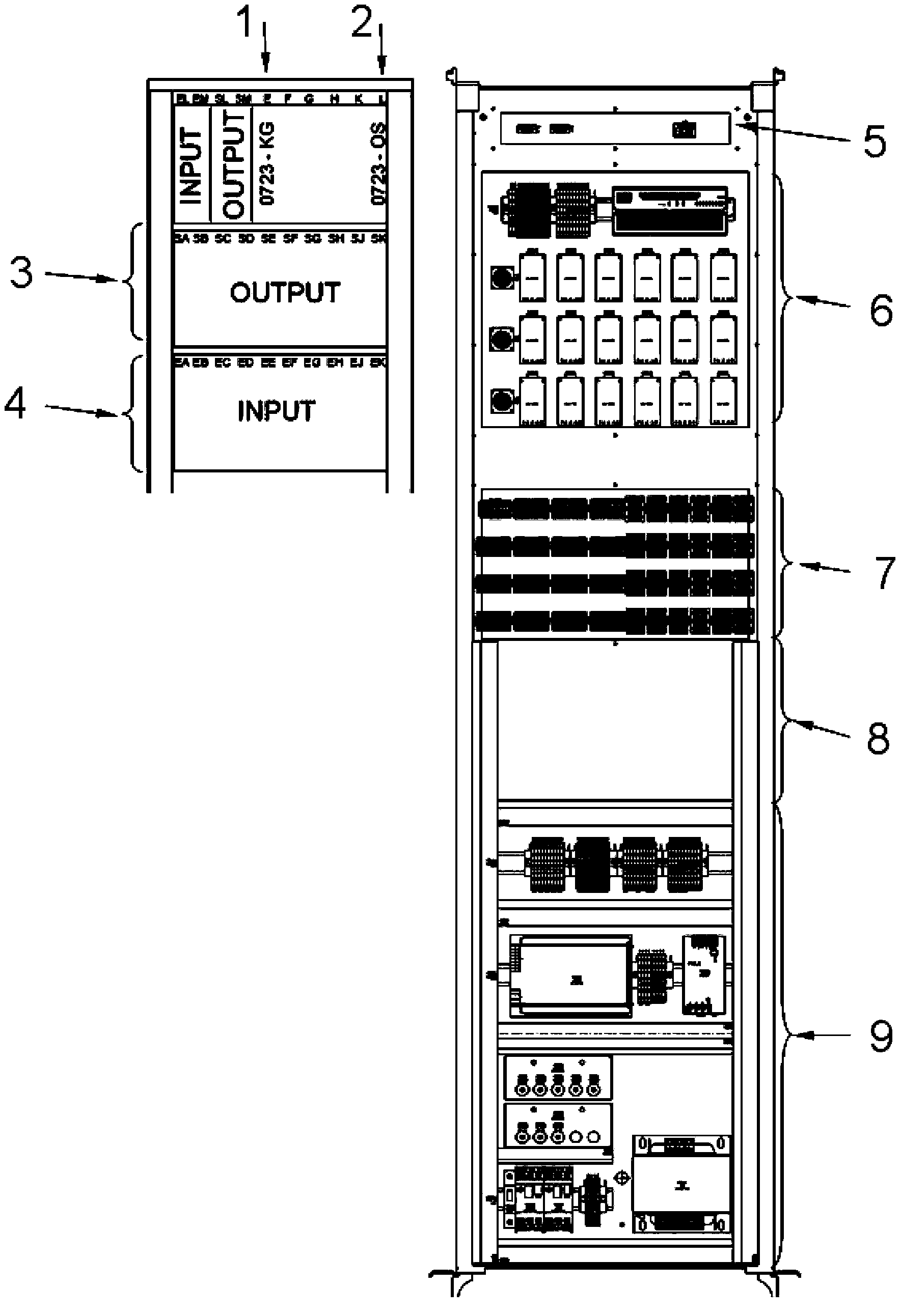

[0016] like figure 1 As shown, a die-cut electromechanical cabinet test device includes a central processing circuit board 1, a power phase circuit board 2, an output circuit board 3, an input circuit board 4, a signal cable interface 5, a standard cable interface 7, and a power phase working circuit board. Module 6, power supply module 9, the output circuit board 3, input circuit board 4, signal cable interface 5, and jumper board 8 are respectively connected with the central processing circuit board 1, and the power supply module 9 passes through the power supply phase working module 6 in turn 1. The power phase circuit board 2 is connected to the central processing circuit board 1, the jumper board 8 is connected to the input circuit board 4 and the output circuit board 3, the standard cable interface 7 is connected to the electric cabinet and the jumper board 8, and the central processing The circuit board 1 is connected to the host computer. Its specific hardware structu...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap