Wiring mechanism, permanent-magnetic adjustable-speed motor, and centrifugal refrigeration compressor

一种永磁调速、接线板的技术,应用在机电装置、电路、连接等方向,能够解决可靠性低、生产困难、体积大等问题,达到可靠性和安全性高、减少装配工序、集成化程度高的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to solve the problem of high temperature, a wiring mechanism to reduce the heating effect, a permanent magnet speed regulating motor and a centrifugal refrigeration compressor are proposed.

[0033] The above and other technical features and advantages of the present invention will be described in more detail below in conjunction with the accompanying drawings.

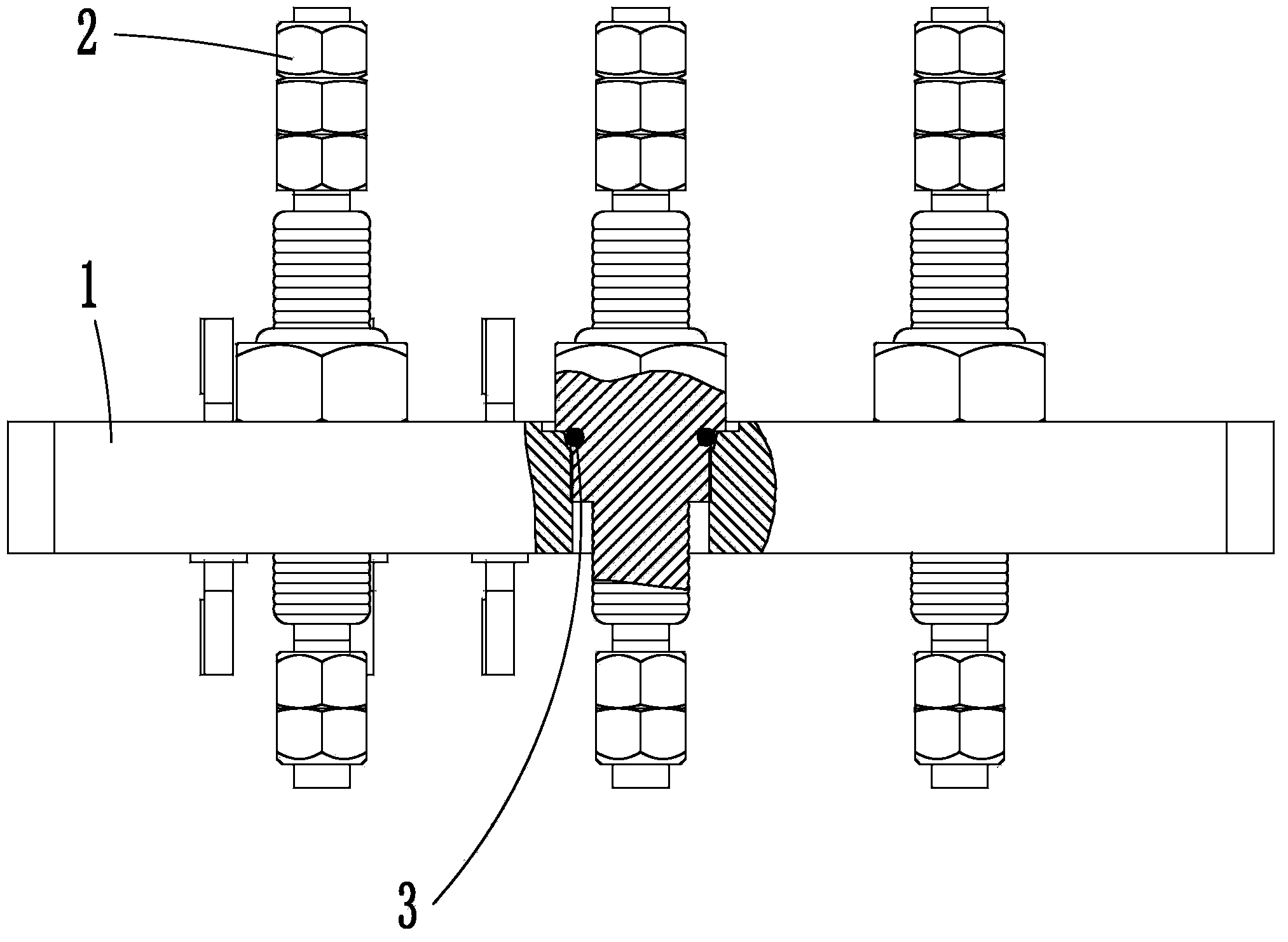

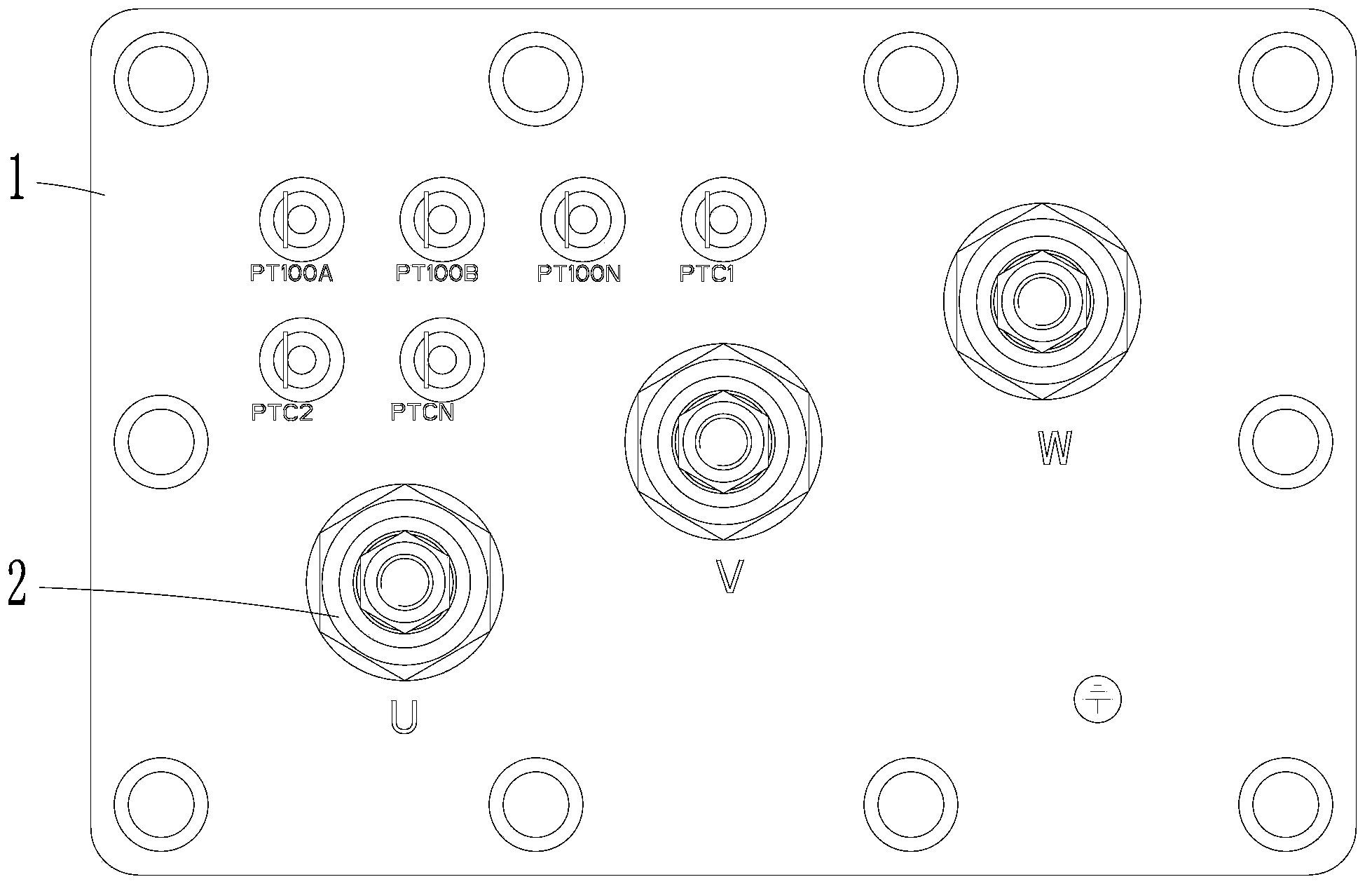

[0034] see figure 1 As shown, it is a schematic front view of the wiring mechanism, and the wiring mechanism includes a wiring board 1 , a power terminal 2 and a sealing ring 3 .

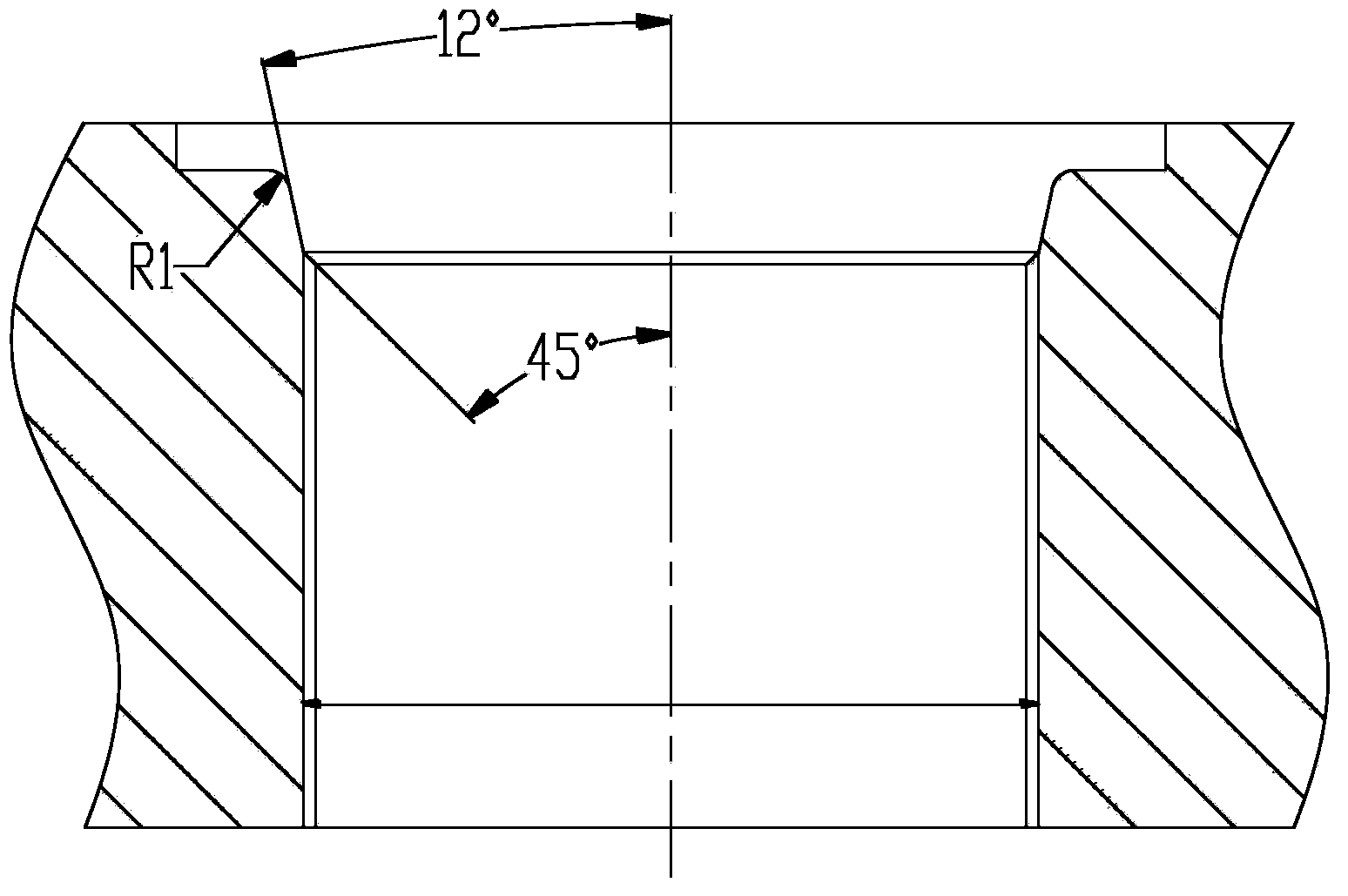

[0035] The wiring board 1 is a flat plate, and the material of the wiring board 1 is steel. In order to avoid heating of the wiring board due to eddy current, the magnetic permeability μ of the steel is not greater than 1.31×10 -6 H / m (magnetic induction B=μH). The steel is preferably non-magnetic steel, which refers to stable austenitic steel that has no ferromagnetism and cannot be magnetized; the metallographic structur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com