Positive-pressure joint for needleless medicated transfusion

A technology of crimping joints and sockets, applied in the field of medical devices, can solve the problems of inconvenient clinical use, waste of medicinal solution, insufficient positive pressure, etc., and achieves the effect of high market recognition, guaranteeing accuracy, and reducing residual amount.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

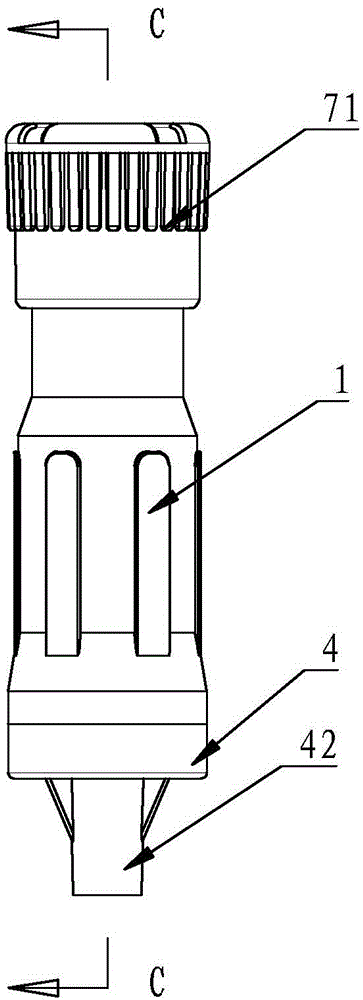

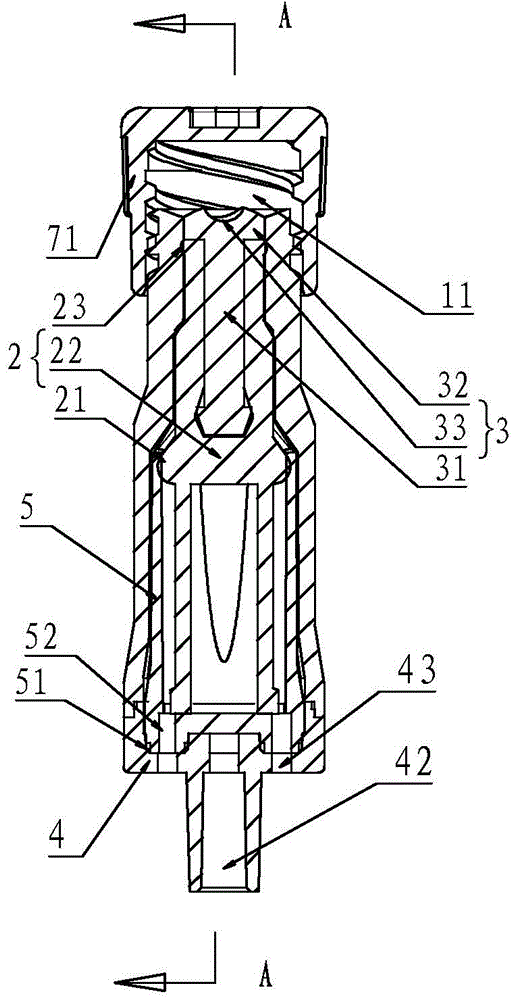

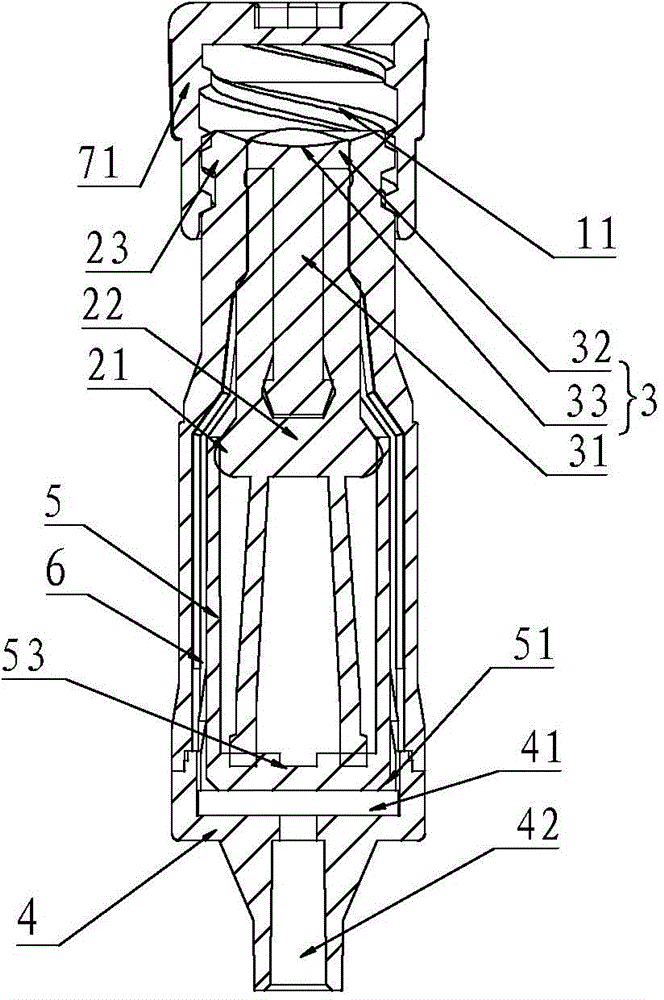

[0026] see Figure 1 to Figure 5 , a positive pressure connector for needle-free drug dosing infusion of the present invention, comprising a housing 1, a hollow rubber plug 2, a socket 4 and a rubber plug housing 5.

[0027] The upper and lower ends of the shell 1 are continuous.

[0028] The socket 4 is socketed on the lower end of the shell 1, and the top surface of the socket 4 is ring-shaped, and the top surface of the socket 4 is provided with an annular boss that can be socketed with the inner peripheral wall of the lower end of the shell 1. The socket 4 is socketed with the lower end of the casing 1 through the annular boss.

[0029] The bottom surface of the inner wall of the socket 4 is provided with a horizontal drainage groove 41 that divides the bottom surface horizontally. Connect the infusion tube 42. The left and right sides of the horizontal drainage groove 41 are respectively provided with an exhaust through hole 43 .

[0030] The rubber plug housing 5 is ...

no. 2 example

[0050] In this embodiment, a dosing tube 12 is added to the shell 1, which is used for tonifying the medicine during the infusion process of the positive pressure connector for the needle-free dosing infusion. One end of the dosing tube 12 is open, and the outer peripheral wall is provided with a second external thread 13 , and a second screw cap 72 is sleeved on the second external thread 13 to protect the external thread 13 . The other end of the dosing tube 12 communicates with a set of longitudinal drainage grooves 6 between the outer peripheral wall of the rubber plug housing 5 and the radial direction of the inner peripheral wall of the housing 1, so that the medicinal solution added through the dosing tube 12 can pass through the horizontal drainage grooves 41 and infusion tube 42 input in the human body. The second screw-on cap 72 is made of medical polyethylene and is opaque.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com