Automotive filter casing drawing machine

A filter and stretching machine technology, applied to vehicle parts, transportation and packaging, etc., can solve the problems of manual operation, low degree of automation, and many faults, and achieve high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

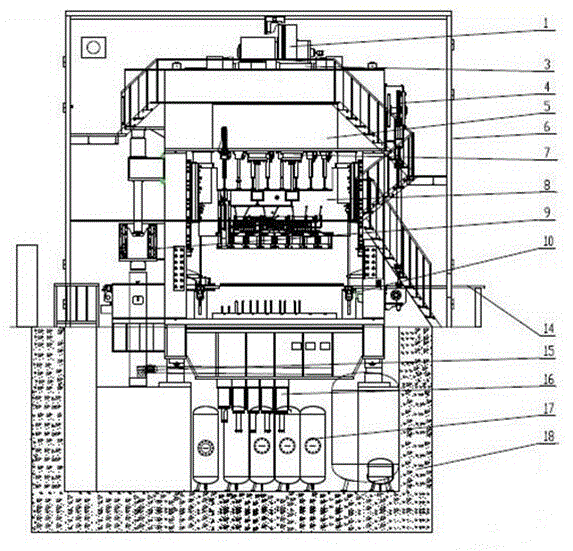

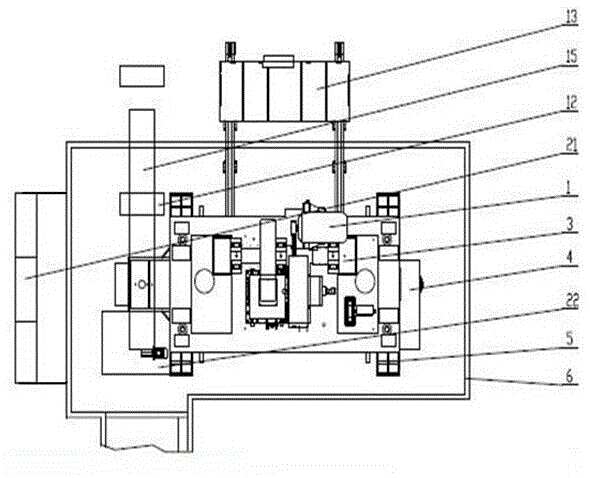

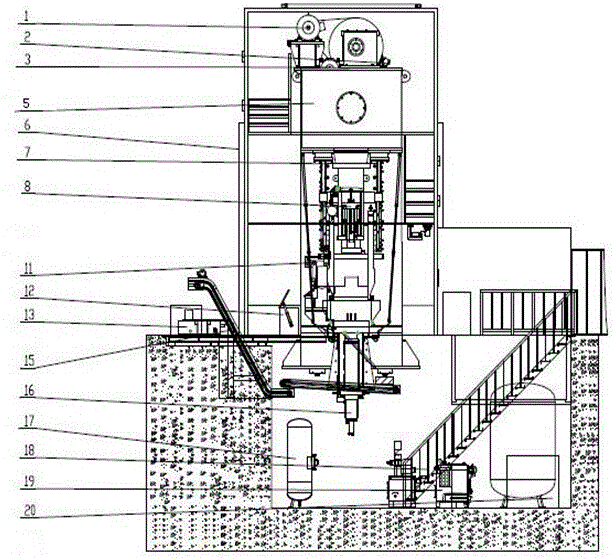

[0029] Examples, see attached figure 1 , 2 , 3, a kind of automobile filter shell stretching machine, comprise filter shell stretching fuselage part 5, filter shell puller is housed above the filter shell stretching fuselage part 5 Stretching transmission system 3, filter housing stretching clutch and brake 1 and filter housing stretching flywheel brake 2 are installed above the filter housing stretching machine transmission system 3; The left side of the stretching fuselage part 5 is equipped with an automobile filter housing stretching auxiliary slider mechanism 9, and a filter housing stretching mechanism is installed under the right side of the filter housing stretching fuselage part 5. The splint opening and closing mechanism 10; the filter housing stretching finished material delivery mechanism 14 is installed on the right side of the filter housing stretching splint opening and closing mechanism 10; the filter housing stretching machine is installed on the In the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com