Laser scribing device for photovoltaic cells

A photovoltaic cell and laser scribing technology, applied in laser welding equipment, circuits, electrical components, etc., can solve the problems of high-quality products connected, different force, product cost increase, etc., to solve the problem of debris and cracks, The effect of avoiding electrical stress and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

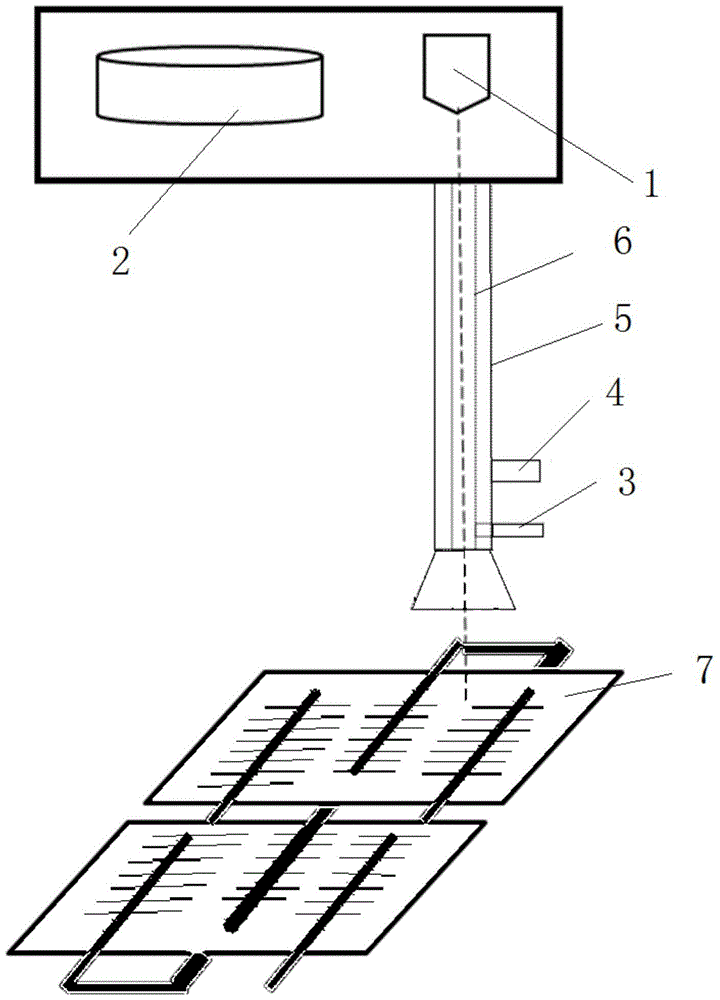

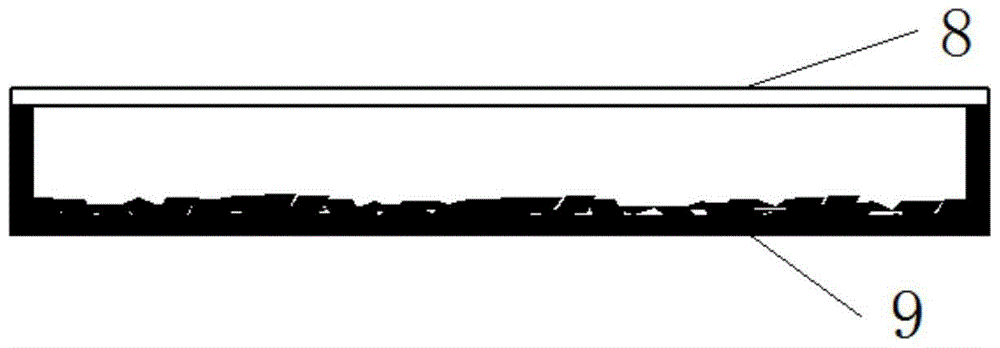

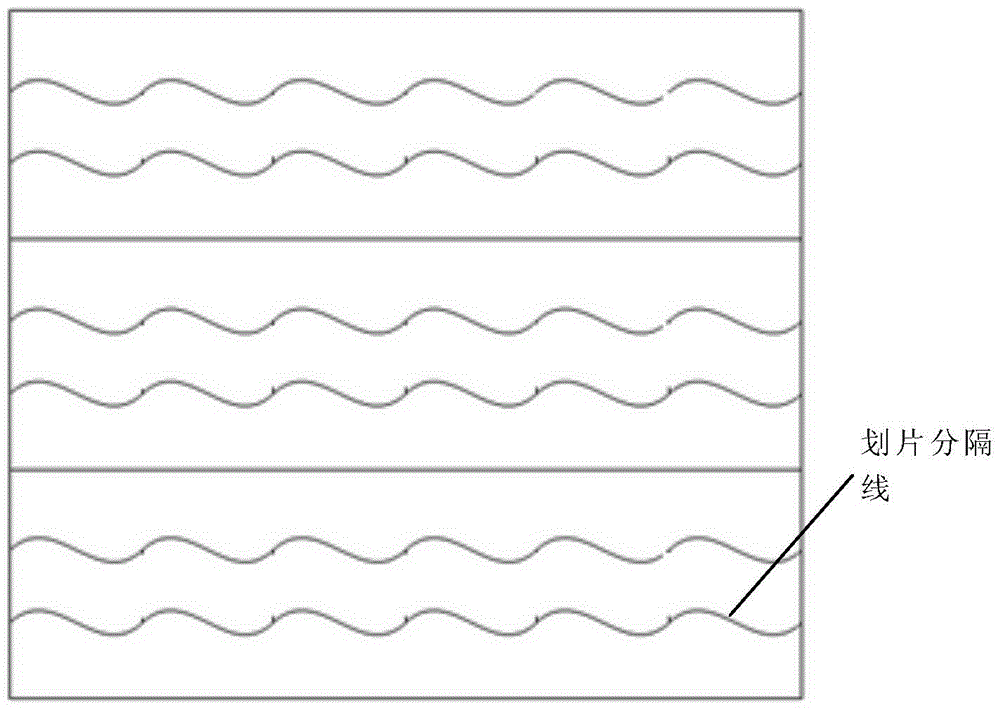

[0021] Such as figure 1 As shown, a laser scribing device for photovoltaic cells includes a laser source 1, an inner tube structure 6, an outer tube structure 5, an oxidizing gas source, an air extraction system and a scribing workbench 8, and the outer tube structure 5 is set Outside the inner tube structure 6, the end of the outer tube structure 5 close to the photovoltaic cell 7 is a bell mouth, and the beam emitted by the laser source 1 passes through the inner tube structure 6 and then shines on the scribing table 8 where the photovoltaic cell 7 is placed , the inner pipe structure 6 has a vent pipe 3 for connecting the oxidizing gas source, the oxidizing gas of the oxidizing gas source enters the inner pipe structure 6 through the vent pipe 3, and is sprayed to the front of the laser scribing through the inner pipe structure 6, On the outer pipe structure 5 there is an air extraction pipe 4 for connecting the air extraction system, the air extraction system is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com