A heat treatment quenching pool

A quenching pool and pool body technology, applied in the field of machinery, can solve the problems of slow cooling speed, high cost, and high energy consumption of workpieces, and achieve the effects of ensuring cooling speed, improving hardenability, and increasing cooling speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

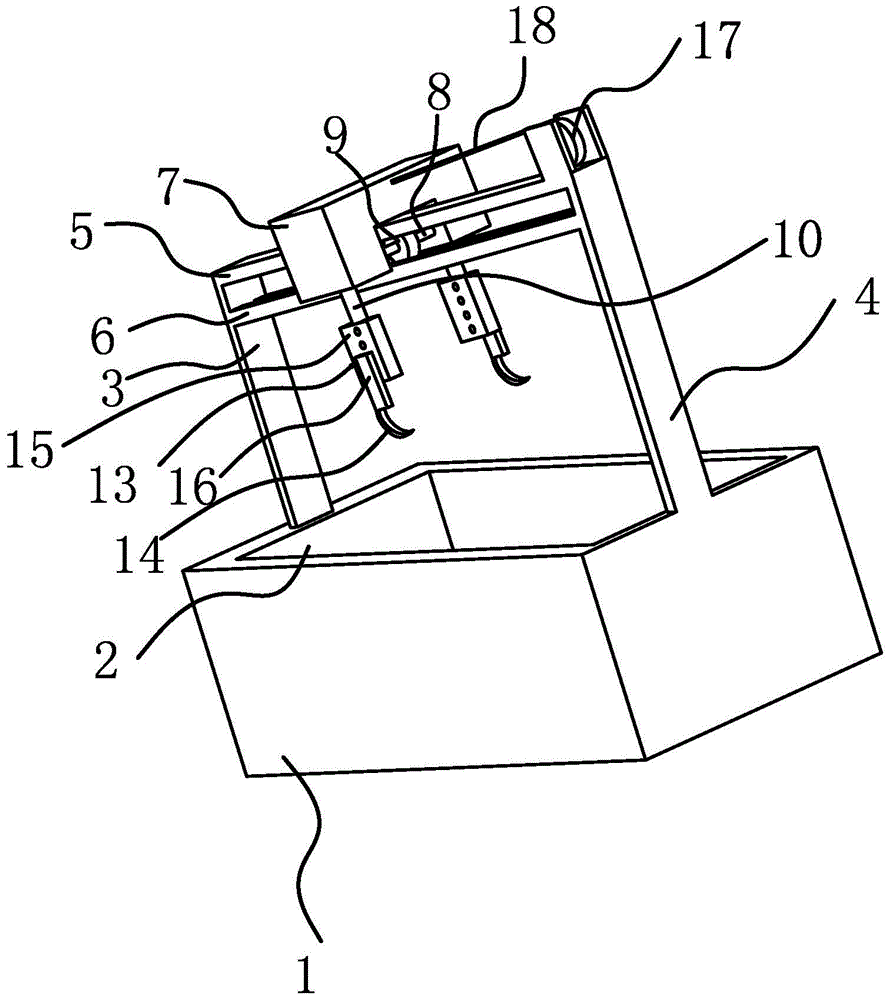

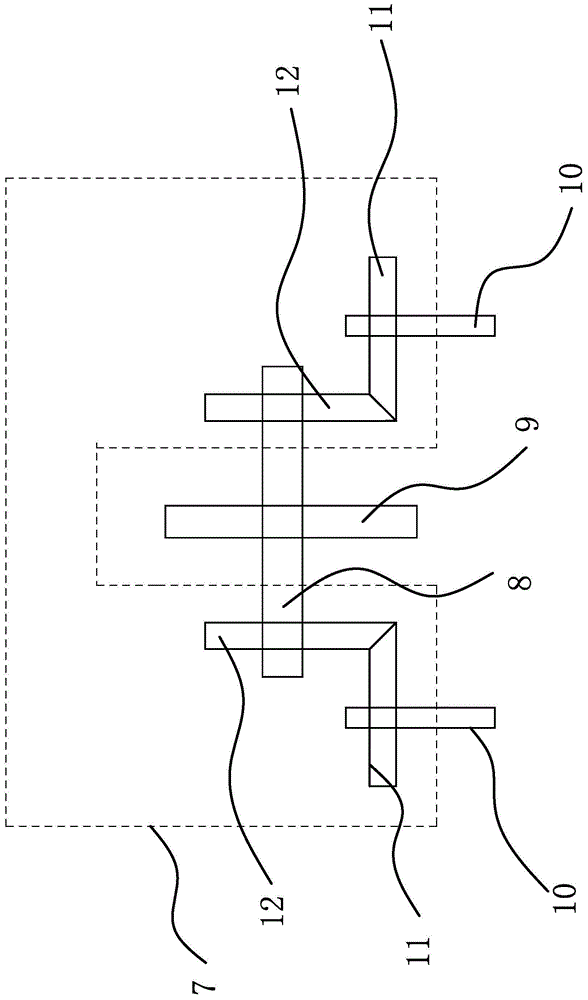

[0029] Such as figure 1 , figure 2 As shown, the quenching pool includes: a pool body 1, the pool body 1 is in the shape of a cuboid, and a groove 2 for containing cooling liquid is opened in the pool body 1; a low column 3 is vertically fixed on one side of the pool body 1 The high column 4 is vertically fixed on the other side of the pool body 1 and is set opposite to the low column 3; the upper slide rail 5 and the two ends of the upper slide rail 5 are respectively fixed on the upper end of the low column 3 and the high column 4 the upper end of the lower rail 6, the lower rail 6 is located directly below the upper rail 5 and parallel to the upper rail 5, and the two ends of the lower rail 6 are respectively fixed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com