Reinforced plastic cable wells

A technology for strengthening structures and cable wells, applied in the field of electric power construction or construction, can solve problems such as strength reduction, waste of clay resources, easy corrosion and peeling, etc., to absorb and buffer vibration and pressure, reduce the impact of road traffic, acid resistance and good alkaline effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

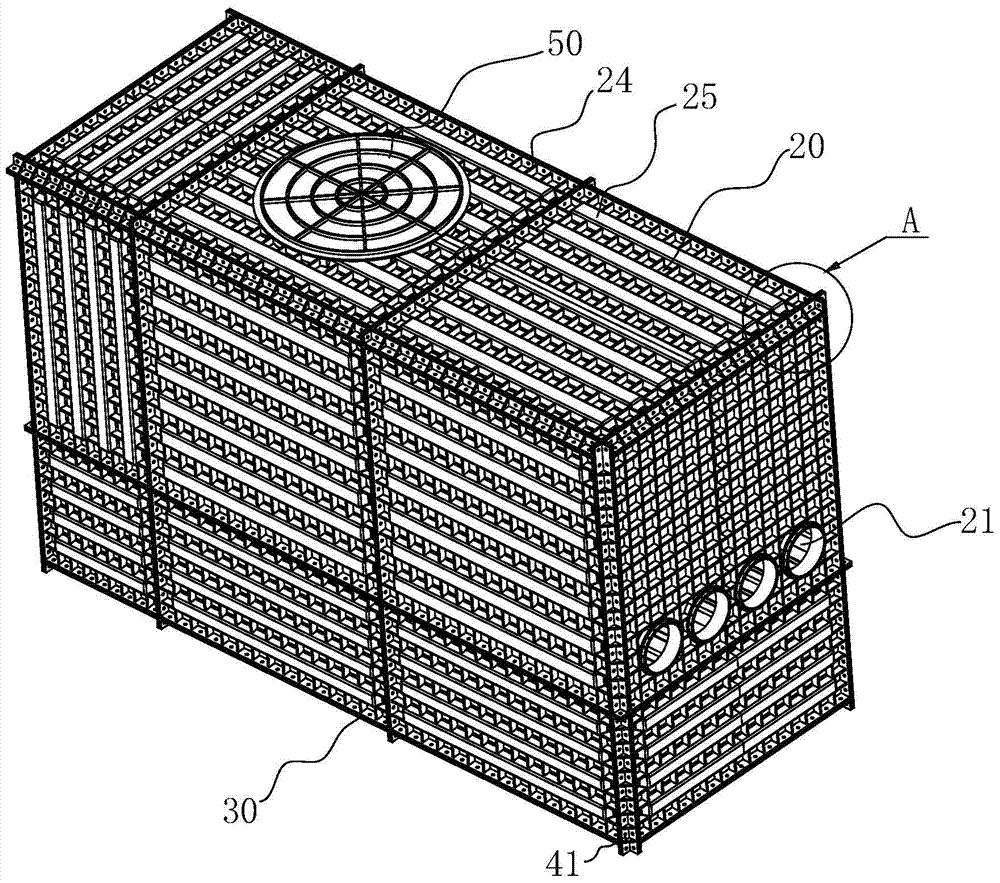

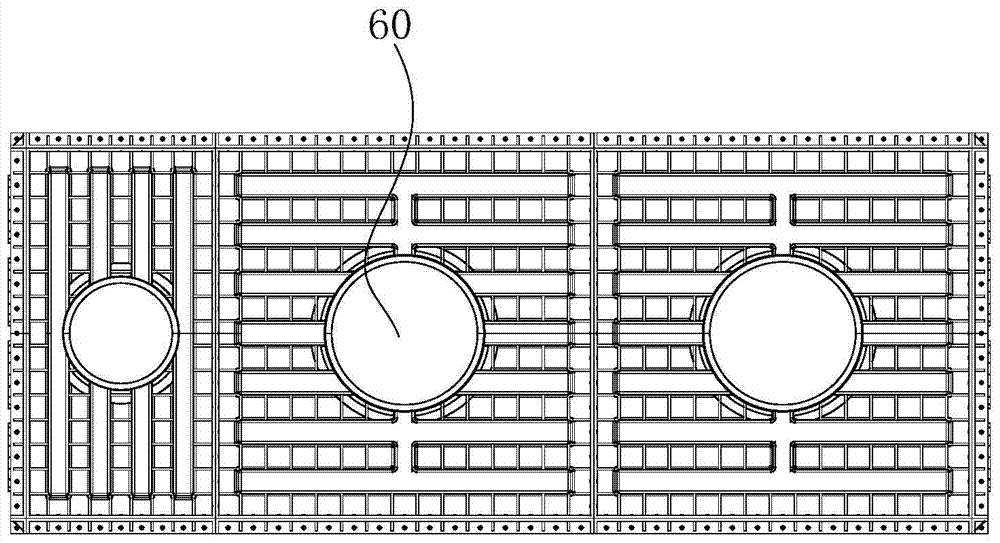

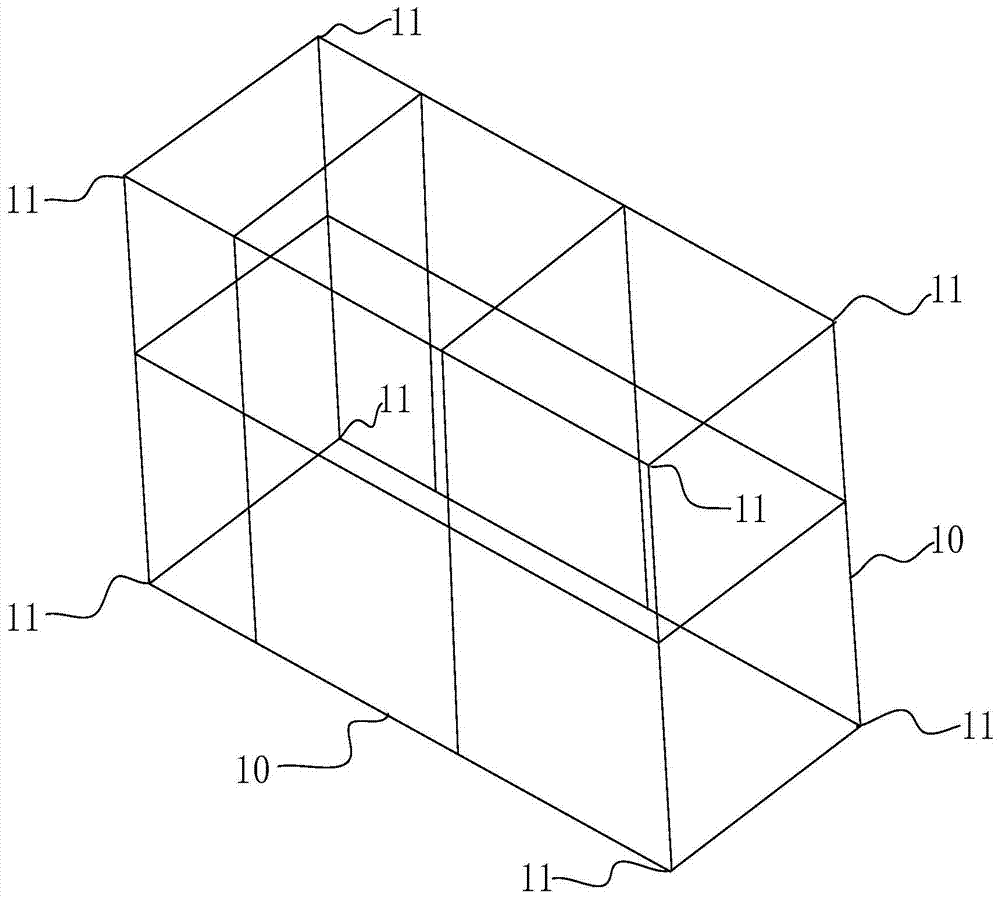

[0017] Such as figure 1 , 2 , The plastic cable well of the reinforced structure shown in 3 and 4, the cable well includes a box-shaped well body, and the improvement of the present invention is that the well body includes internal such as image 3 The metal frame shown and set outside the metal frame such as figure 1 See the casing, the casing is made of plastic material, the casing is provided with a wire inlet 21, and one end opposite to the wire inlet 21, that is, the side opposite to the wire inlet 21 in the length direction of the well body is set Outlet hole, well body upper side is provided with manhole 50 or hand hole, and general large well body is exactly manhole, and small well body is exactly hand hole. The outer surface of the shell is uniformly staggered with reinforcing ribs, and the staggered setting of the reinforcing ribs is criss-cross or obliquely staggered, which can better support the shell and strengthen the structure; such ribs can also be set inside...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com