Noise control method of wideband composite sound absorption structure-based steam turbine generator unit

A turbo-generator set and noise control technology, applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve the problems of skin irritation, high water absorption, easy deformation and blockage, etc., and achieve noise reduction and noise reduction effects Obvious and economically beneficial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

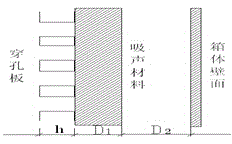

Method used

Image

Examples

Embodiment

[0018] 1 Noise analysis

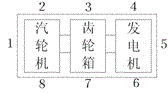

[0019] The near-field noise of the steam turbine unit is evaluated by the noise level 1 meter away from the unit. The operators of this unit work 8 hours a day and are exposed to the noise field. The maximum allowable noise level under this condition is 90dB(A). Due to the limitation of the site near the unit, the measuring points of the unit are arranged as follows figure 1 .

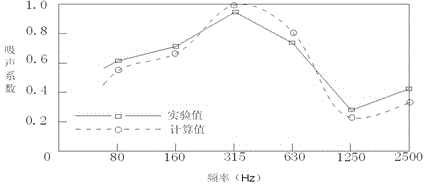

[0020] The original noise value is shown in the figure, the noise of the entire steam turbine unit far exceeds the standard value of 90dB, and the average noise value reaches 111.5 dB, especially the noise value of measuring point 2 reaches 118dB, which shows that the exhaust port of the steam turbine under the same environment and the noise level at the generator is maximum. In order to analyze the noise components of the unit, the noise spectrum test was carried out on the three measuring points 2, 4, and 6 respectively. The results are shown in Table 1:

[0021] Table 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com