Rigidity-adjustable type ship model sea load vertical bending moment measuring device

A wave load, vertical bending moment technology, applied in the direction of measuring device, torque measurement, power measurement, etc., can solve the problems of difficult to find steel, the impact of measurement accuracy, manpower, material resources and time waste, to improve accuracy degree, achieve adjustability, and improve the effect of reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

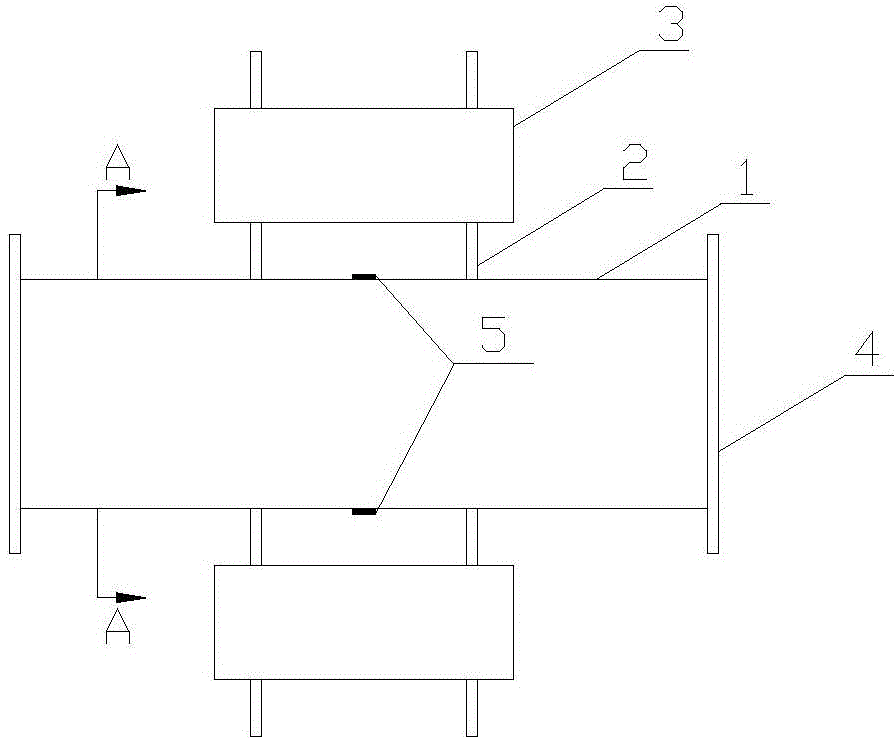

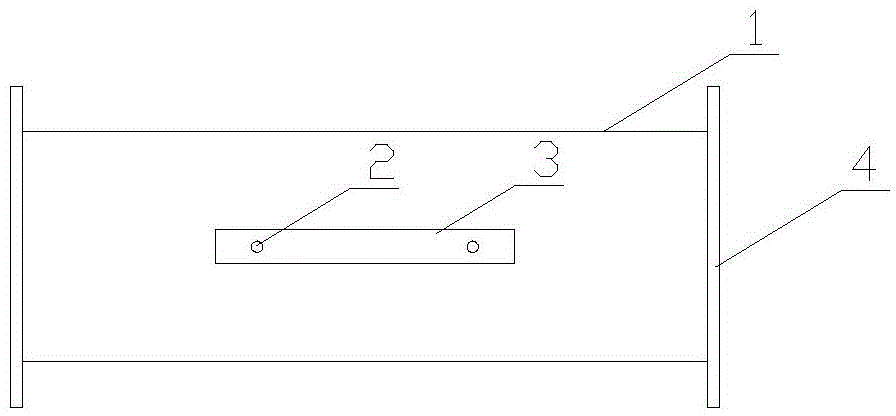

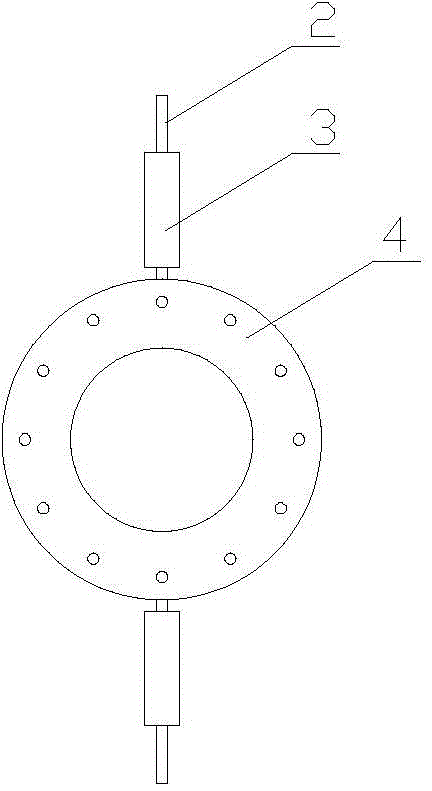

[0015] The invention relates to a ship model vertical bending moment measuring device whose stiffness can be adjusted. For the three views and section views of the device, see Figure 1 to Figure 4 , consists of the following five parts: a circular steel pipe 1; two solid steel bars 2 rigidly connected to the circular steel pipe 1, arranged symmetrically from left to right; A steel slider 3 is symmetrically arranged up and down; a flange 4 rigidly connected to the left and right ends of the circular steel pipe 1; two unidirectional strain gauges 5 pasted on the upper and lower surfaces of the circular steel pipe 1, the The length direction of the shaped steel pipe 1 is connected by a half-bridge bridge way to realize the measurement of the vertical bending moment.

[0016] The schematic diagram of the installation of this device in the shi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com