Visual detection method and device for defects of liquid crystal display screen

A visual inspection, liquid crystal technology, applied in nonlinear optics, instruments, optics, etc., can solve problems such as manual inspection of liquid crystal screen defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

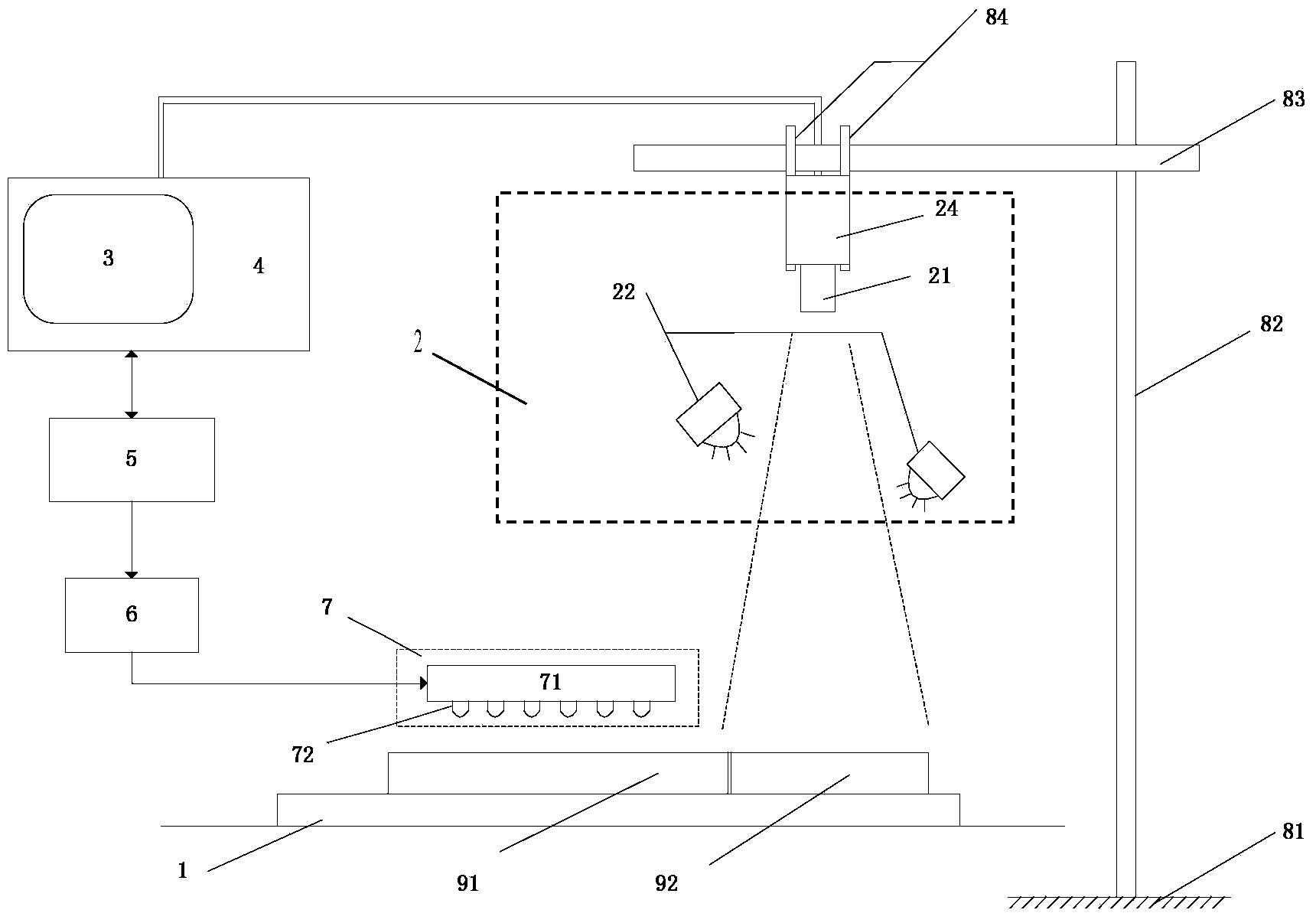

[0061] like figure 1As shown, a liquid crystal screen defect visual detection system device of the present invention includes:

[0062] A support composed of a support base 81 , a vertical support 82 , a horizontal support 83 and a fixing clip 84 . The camera acquisition device 2 is installed on the horizontal support 83 through a fixing clip, and the horizontal support 83 is connected with the vertical support 82 and fixed on the support base 81 . The vertical height of the camera acquisition device 2 can be adjusted by moving the horizontal bracket 83 up and down, and the horizontal position of the camera acquisition device 2 can be adjusted by moving the fixing clip 84 left and right.

[0063] The sample to be tested includes a keyboard area 91 and a liquid crystal display area 92. The acquisition lens 21 of the camera acquisition device 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com