Closed switching device, and arc extinguish chamber and tank of closed switching device

A technology for arc extinguishing chambers and tanks, which is applied in the direction of switchgear, switchgear settings, electrical components, etc., and can solve problems such as uneven inner wall surface of the tank, rising insulating gas pressure, and breakdown

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

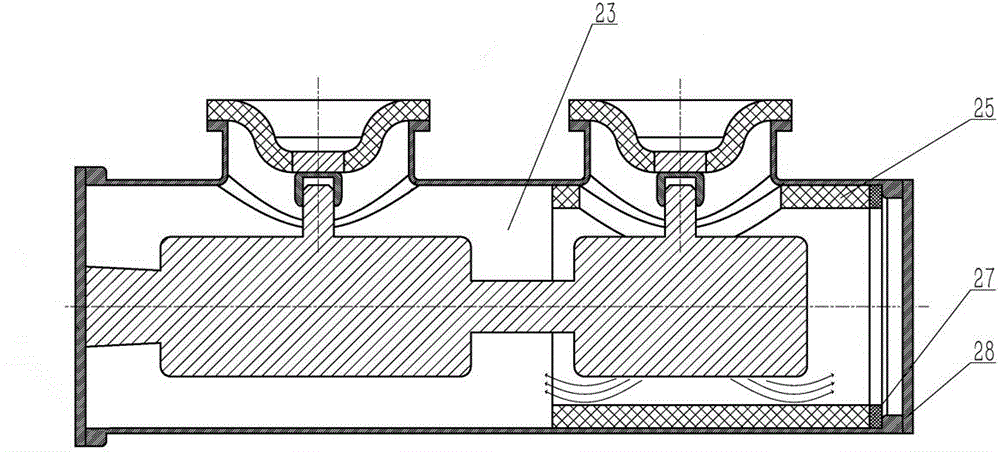

[0035] Embodiment 2 of the enclosed switchgear in the present invention: The difference between this embodiment and Embodiment 1 is that, as figure 2 As shown, the right end of the solid insulating sleeve 25 presses against the left side of the limit ring, that is, the right end of the solid insulating sleeve 25 presses against the left side of the inner flange 28, and the inner flange 28 and the solid insulation An annular peripheral surface adhesive layer 27 is arranged between the sleeves 25, and the inner hole diameter of the peripheral surface adhesive layer 27 is equal to the aperture of the solid insulating sleeve 25, and the outer wall surface of the solid insulating sleeve 25 is the same as the inner wall surface of the tank body 23. The interference fit is such that the solid insulating sleeve 25 is bonded and fixed on the inner flange 28 through the end face bonding layer 27 . In this way, when the solid insulating sleeve 25 needs to be packed into the tank body 23...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com