Method for shrinkage fit of protective ring of 50kW ultrahigh-speed permanent magnetic generator rotor

A permanent magnet generator, ultra-high-speed technology, applied in the manufacture of the stator/rotor body, etc., can solve the problems of thin wall of the retaining ring, small heat capacity, easy cooling, and inability to heat fit, etc., and achieve the effect of meeting the requirements of the heat fit of the retaining ring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to enable those skilled in the art to better understand the technical solution of the present invention, its specific implementation will be described in detail below in conjunction with the accompanying drawings:

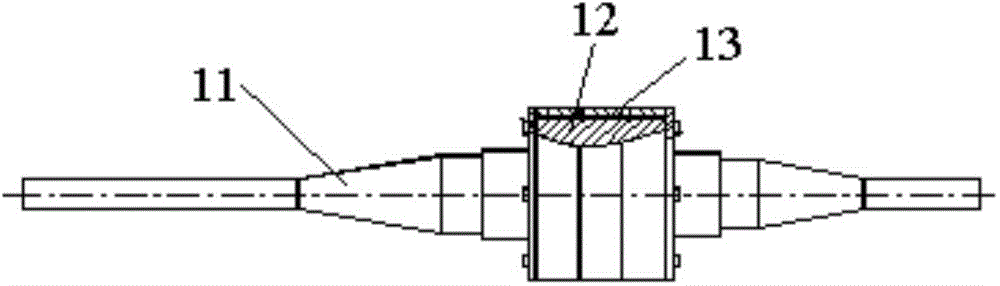

[0023] Please refer to the figure, the rotor of the 50kW ultra-high speed permanent magnet generator includes a rotating shaft 11, a magnetic yoke 12 that is shrink-fitted on the outer circle of the rotating shaft 11, and a magnetic steel 13 installed on the outer circumferential surface of the magnetic yoke 12, and the retaining ring is circular. The cylindrical structure, the wall of the guard ring is thin, and the guard ring is sleeved on the outer circle of the magnetic steel 13 .

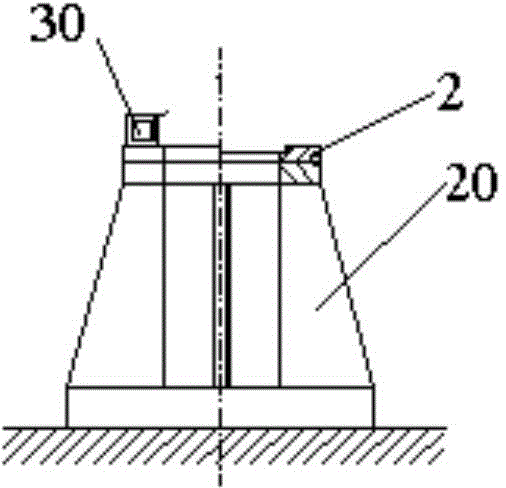

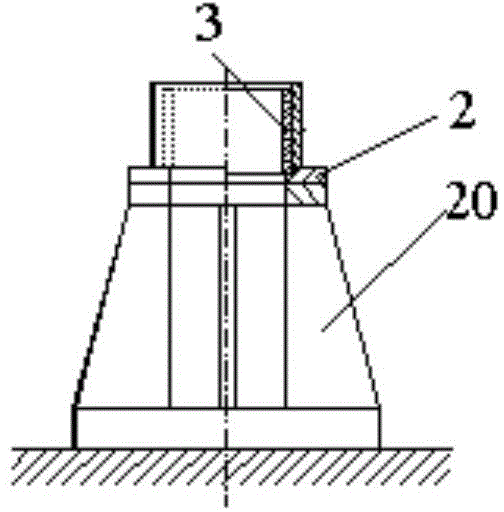

[0024] For an example of the invention, see Figure 2 to Figure 7 , a 50kW ultra-high-speed permanent magnet generator rotor retaining ring shrink-fit method, comprising the following steps:

[0025] S1, the step of processing the support plate: the support plate 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com