Method for on line identifying and dynamically inhibiting resonance of electromechanical servo system

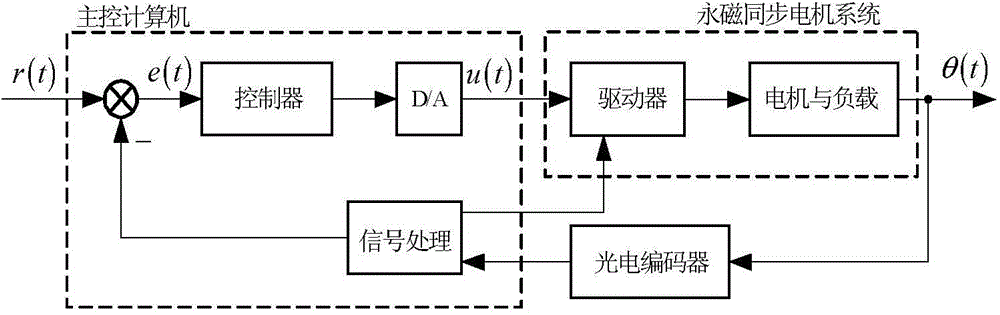

An electromechanical servo system and resonance technology, applied in the field of electromechanical servo systems, can solve the problems of consuming manpower and material resources, endangering electromechanical servo systems, and poor reliability of electromechanical servo systems, so as to save manpower and material resources and ensure reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

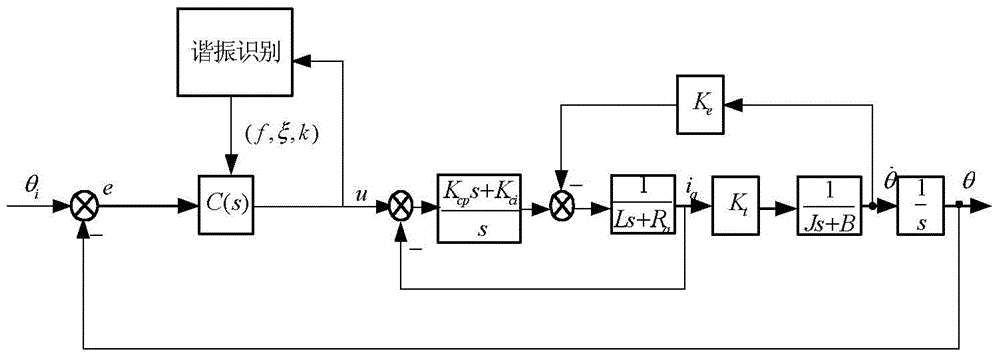

Method used

Image

Examples

specific Embodiment approach 1

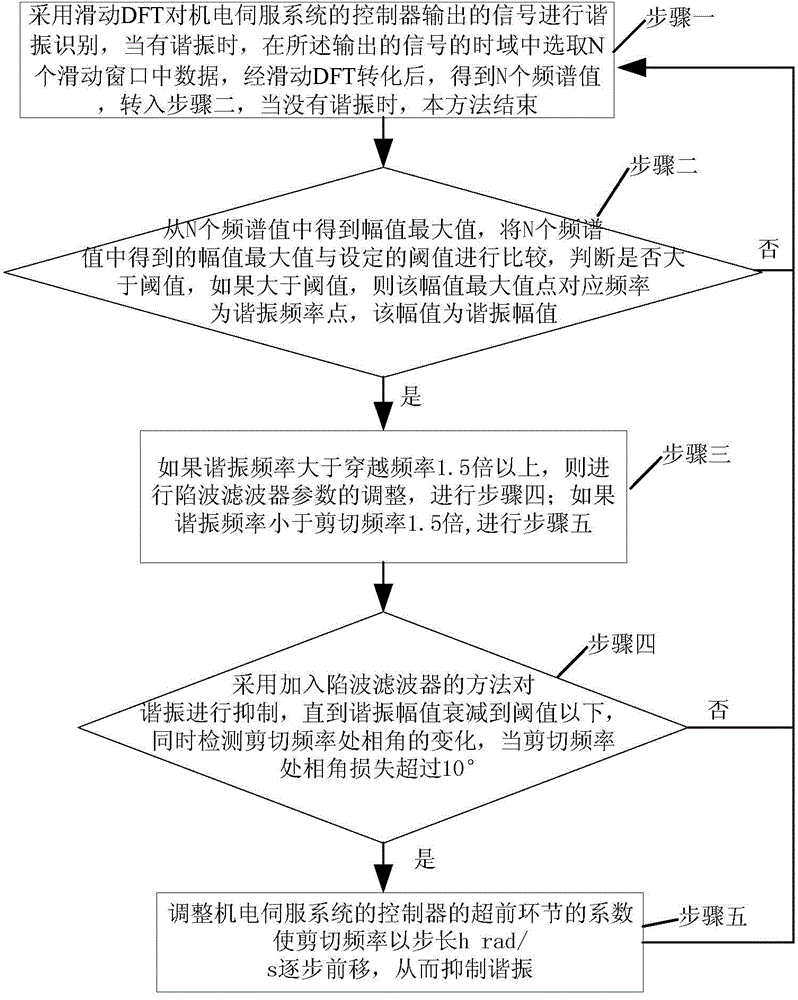

[0019] Specific implementation mode one: refer to image 3 Specifically illustrate the present embodiment, the electromechanical servo system resonance online identification and dynamic suppression method described in the present embodiment, it comprises the following steps:

[0020] Step 1. Using sliding DFT to carry out resonance identification on the signal output by the controller of the electromechanical servo system. When there is resonance, select the data in N sliding windows in the time domain of the output signal, and convert it through sliding DFT to obtain N spectral values, turn to step 2, when there is no resonance, the method ends;

[0021] Step 2. Obtain the maximum value H of the amplitude from the N spectrum values max , the maximum amplitude H obtained from the N spectrum values max with the set threshold H th Compare and judge H max Is it greater than the threshold H th , if H max is greater than the threshold, then the maximum value of the amplitude ...

specific Embodiment approach 2

[0025] Specific embodiment 2: This embodiment is to further explain the resonance online identification and dynamic suppression method of the electromechanical servo system described in the specific embodiment 1. In this embodiment, the sliding DFT is used in step 1 to output The signal is resonantly identified, and the process of obtaining N spectrum values is as follows:

[0026] According to the fast Fourier transform formula:

[0027] X ( k ) = Σ n = 0 N 2 - 1 x ( 2 n ) W N 2 nk + W N k Σ n ...

specific Embodiment approach 3

[0037] Specific embodiment three: This embodiment is to further explain the electromechanical servo system resonance online identification and dynamic suppression method described in specific embodiment one. suppressed until the resonance amplitude decays to the threshold H th The following process is:

[0038] Decrease the resonance amplitude to the threshold H th The required attenuation amplitude is recorded as ξ is the depth, then at the resonant frequency point f 0 Take points one by one from both sides as the benchmark, set f 0 The spectrum values corresponding to the frequency points on both sides are compared with the set threshold until finding a value less than or equal to the threshold H th The frequency point corresponding to the amplitude of , which is taken as f 1 and f 2 , according to the formula k=2max{(f 0 -f 1 ),(f 2 -f 0 )} to obtain the resonant width k, select the depth ξ and width k as the gradient adjustment to adjust the parameters, set th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com