Mop assembly and mop cleaning and dewatering method

A mop and component technology, which is applied in the field of cleaning and dehydration of mop components and mops, can solve the problems of unsatisfactory dehydration effect of mops, increased labor intensity, small effective blocking part, etc., and achieves labor-saving, convenient cleaning and work in dehydration and cleaning operations. stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

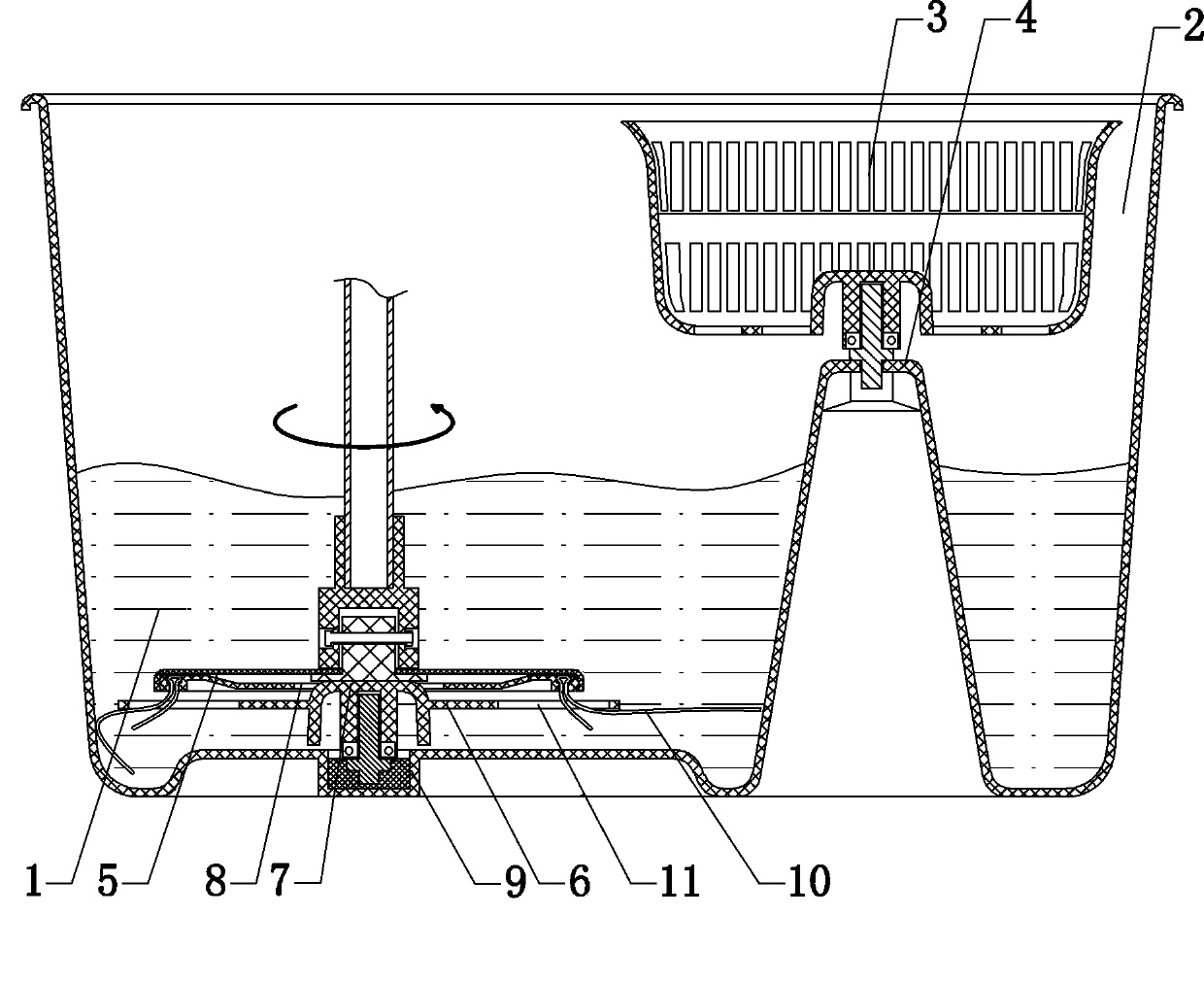

[0046] figure 1 , figure 2 , Figure 5 , Figure 6 , Figure 7 Embodiment 1 of the mop bucket of the present invention is given.

[0047] In this embodiment, a cleaning part 1 and a dehydration part 2 are arranged in the mop bucket, and a rotatable dehydration basket 3 is arranged in the dehydration part. The rotating mop head 5 is driven to rotate. A rotatable cleaning frame 6 is arranged in the cleaning part 1 , and the cleaning frame 6 is arranged at the bottom of the cleaning part 1 , and the cleaning frame 6 is driven to rotate by the rotating mop head 5 .

[0048] In this embodiment, a protrusion 7 is provided in the middle of the cleaning frame, and a positioning portion 8 matching the protrusion is provided in the middle of the mop head 5 . In this embodiment, the positioning portion 8 is an opening. The protrusion at the middle part of the cleaning rack cooperates with the positioning part at the middle part of the mop head to prevent the mop head from slippin...

Embodiment 2

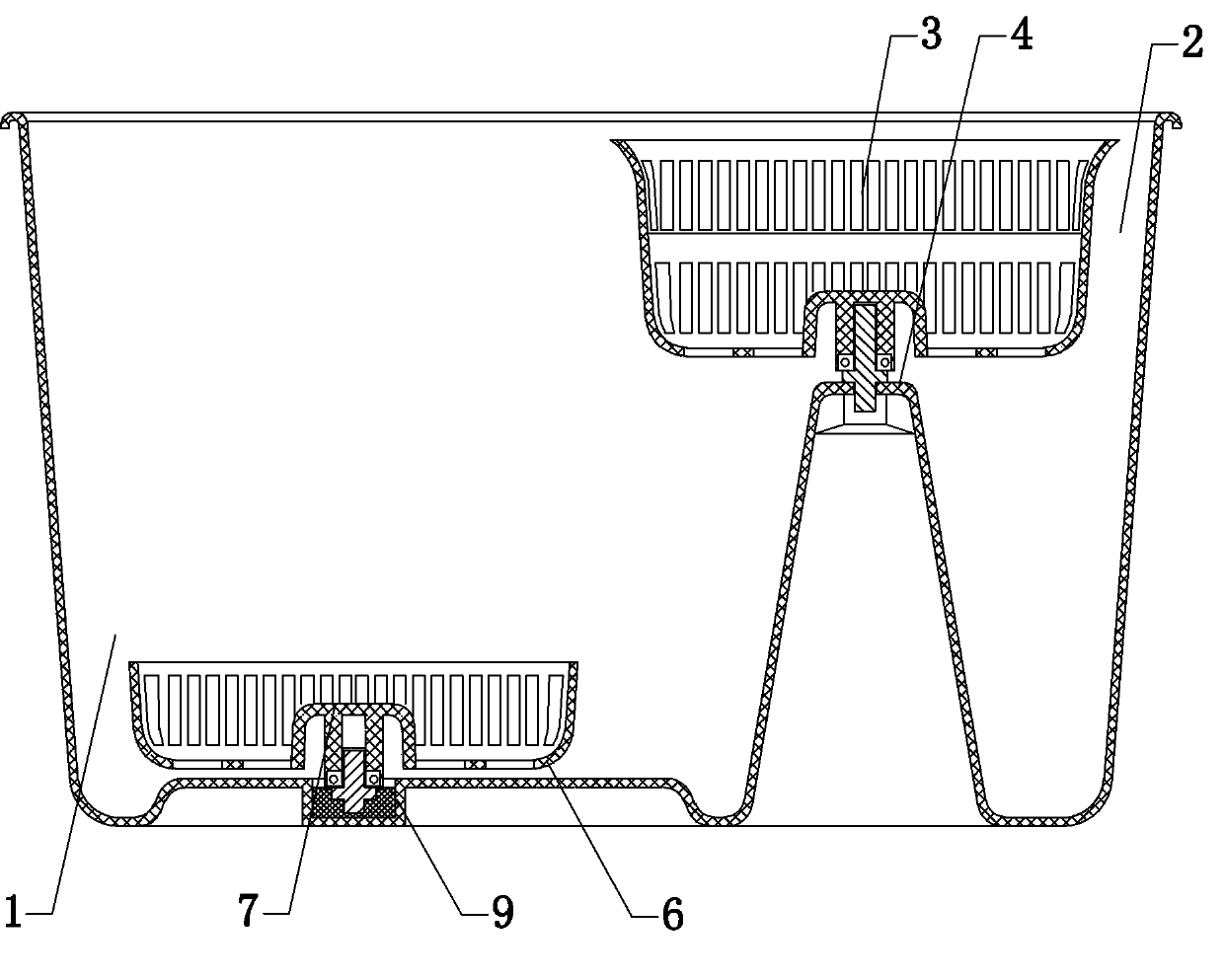

[0054] image 3 Embodiment 2 of the mop bucket of the present invention is given.

[0055] In this embodiment, the cleaning frame 6 interferes with the mop head during cleaning, and at least part of the wipes 10 on the mop head pass through the opening 11 on the cleaning frame. When part of the wipes on the mop head pass through the cleaning rack, the wipes passing through the cleaning rack can be rotated in the water under the drive of the mop head, which can fully contact with the water, and the dirt on the wipes can be wiped in the rotating Under the multiple effects of objects, rotating water and its own centrifugal force, it is easy to be cleaned, and its cleaning effect is very ideal. Simultaneously, the mop bucket can also be cleaned during the rotation process of the wiping objects passing through the cleaning frame. All the other are identical with mop bucket embodiment 1.

Embodiment 3

[0057] Figure 4 Embodiment 3 of the mop bucket of the present invention is given.

[0058] In this embodiment, the cleaning rack 6 is a cleaning basket, and when the mop head is being cleaned, all the wipes on the mop head are placed in the cleaning basket. The cleaning effect of this type of cleaning rack on the wipes is not as good as that of the aforementioned two structures, but its cleaning effect is much better than that of common cleaning methods. At the same time, the cleaning rack can reduce the noise during the cleaning process. All the other are identical with mop bucket embodiment 1.

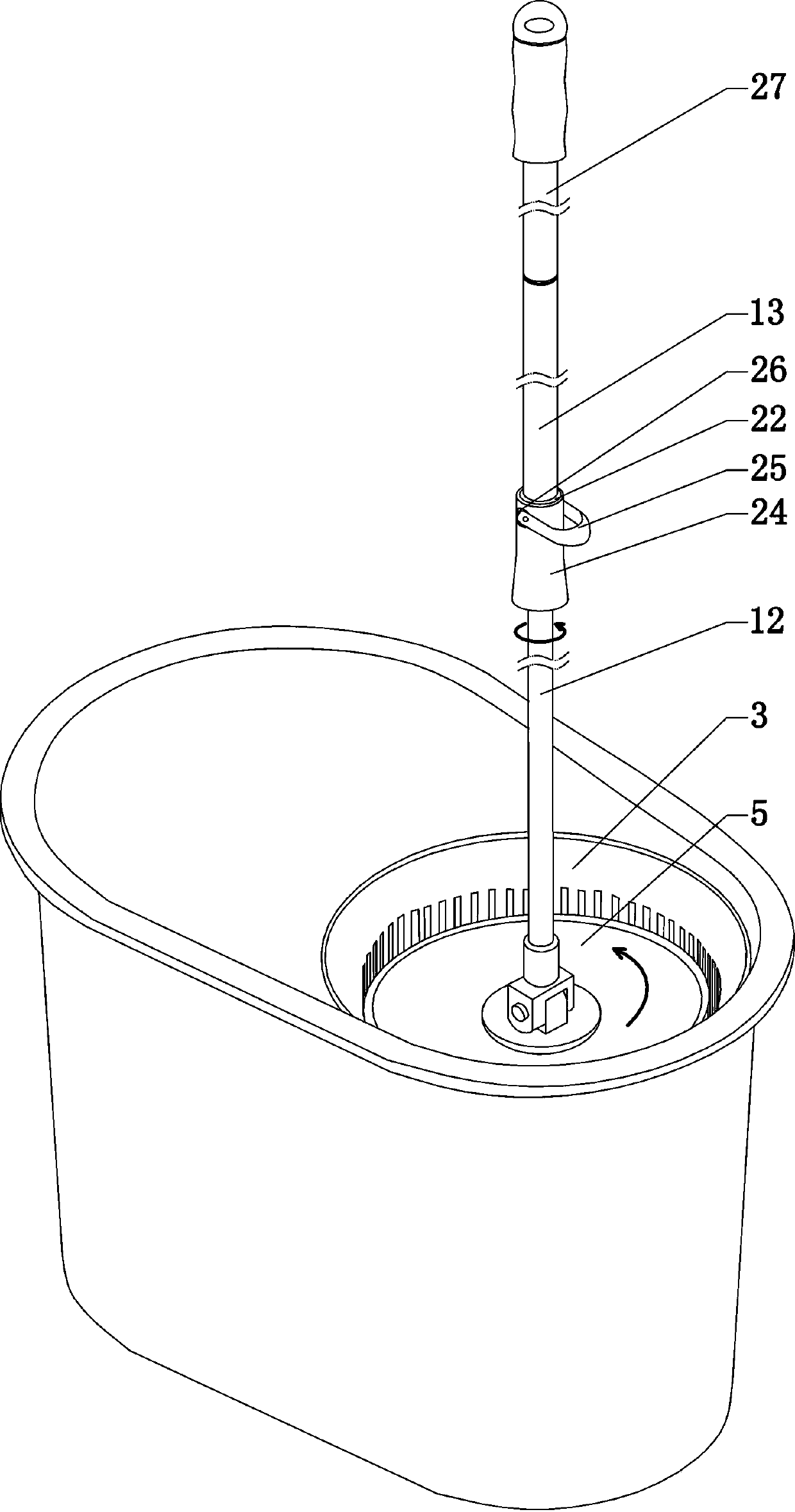

[0059] Mop Example 1.

[0060] Figure 5 , Figure 8 , Figure 9 , Figure 10 , Figure 11 Example 1 of the mop of the present invention is given.

[0061] In this embodiment, the mop matched with the mop bucket includes: the lower end of the mop rod is hinged with a mop head 5 with a wiper 10, and the mop rod at least includes an inner rod 12 and an outer rod 13, which can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com