Pipe end marking device of automatic pipe cutter

A technology of marking device and pipe cutting machine, which is applied in metal processing and other directions, can solve problems such as poor effect and low marking efficiency, and achieve the effect of obvious effect, stable workpiece quality and uniform imprint.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

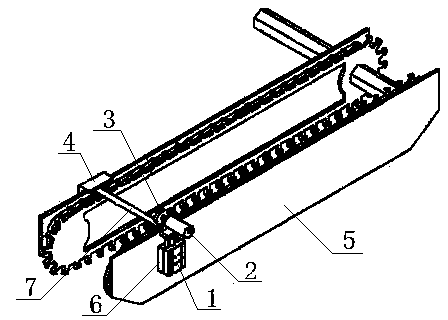

[0013] like figure 1 It is a structural schematic diagram of the present invention, a pipe end marking device for an automatic pipe cutting machine, including a cylinder 1, a motor 2, a brush 3, a baffle 4 and a base guide rail 6, and the baffle 4 and the base guide rail 6 are installed on the automatic pipe cutting machine respectively. On both sides of the motor transmission chain 5, the cylinder 1 is slidably connected on the base guide rail 6, fixed by bolts, the motor 2 is installed on the cylinder 1, and the hairbrush 3 is installed on the motor 2. The motor 2 is connected to the piston rod at the top of the cylinder 1. Hairbrush 3 is disc-shaped, is connected on the rotating shaft of motor 2. The baffle plate 4 and the hair brush 3 are symmetrically distributed on both sides of the transmission chain 5 of the automatic pipe cutting machine, and are pressed on the two ends of the pressure pipe 7 respectively. The baffle plate 4 is "L" shaped and blocks the side and upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com