Tilt rotor submersible device

A submersible and tilting propeller technology, which is applied to underwater ships, underwater operation equipment, propulsion components, etc., can solve the problems of increasing the complexity of the propulsion system, waste of institutional resources, and a large number of propellers, and achieves easy promotion, Simple structure, the effect of reducing complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

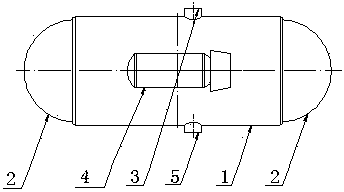

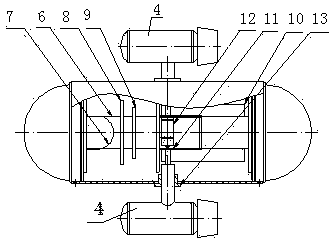

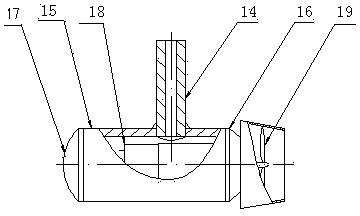

[0018] Such as figure 1 , Figure 5 with Image 6 As shown, the present invention includes a pressure chamber composed of front and rear end covers 2 and a main cylinder 1. Considering weight and strength, the main cylinder 1 can be made of high specific strength materials such as engineering plastics and aluminum alloys. Considering the cost, The present invention is made of engineering plastics; in order to ensure the observability of the field of view, the front and rear end covers 2 are made of transparent materials, such as quartz glass, plexiglass and the like. The main cylinder body 1 and the front and rear end covers 2 are fixed by bolts, and O-rings are used to ensure the watertightness of the connection, and the pressure chamber formed provides the main underwater buoyancy.

[0019] The umbilical cable port 3 is set above the main cylinder 1, and the communication umbilical cable is led out to the water surface through the umbilical cable port 3, and connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com