Rubber face rockfill dam and its construction method

A technology of face rockfill dam and construction method, applied in dams, barrages, water conservancy projects, etc., can solve the problems of low anti-seepage performance, open face joints, etc., and achieve the effects of high strength, simple construction and good plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

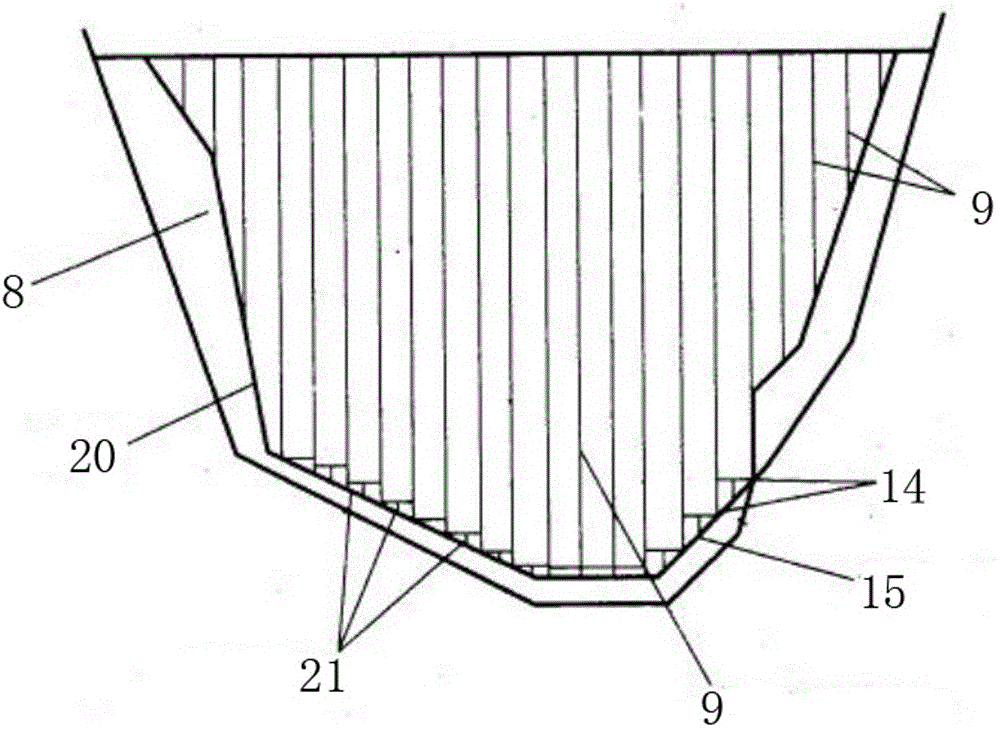

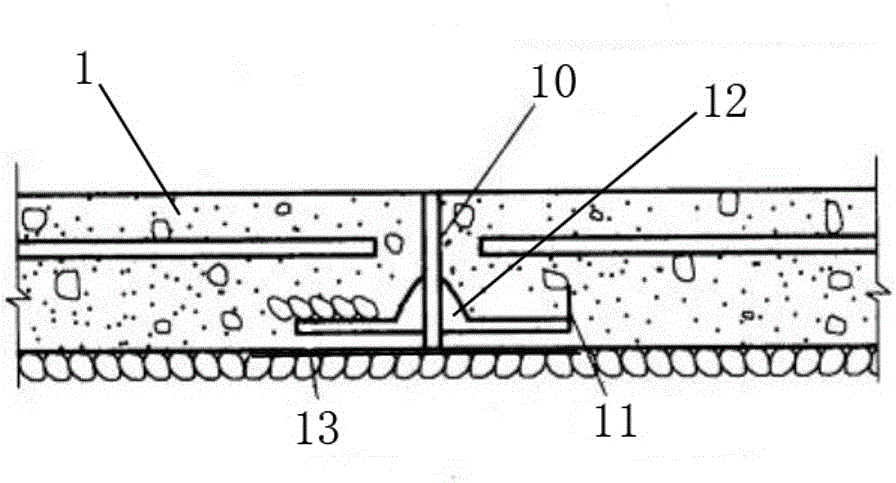

[0024] Example 1: Rubber face rockfill dam, see figure 1 , including the main structure of the rock-fill dam. The main body of the rock-fill dam mainly includes rock-fill bodies (the upstream main rock-fill body and the downstream secondary rock-fill body), wave walls, curtain grouting layers and other structures, and the riverbed is paved with sand and gravel. see image 3 , on the water-facing surface of the main body of the rockfill dam, from the inside to the outside, there are transition layer, dry stone cushion, inner foam board cushion, rubber panel anti-seepage layer, outer foam board layer and bedding layer. Wherein, the rubber panel includes a skeleton on the inside and a rubber layer on the outside of the skeleton.

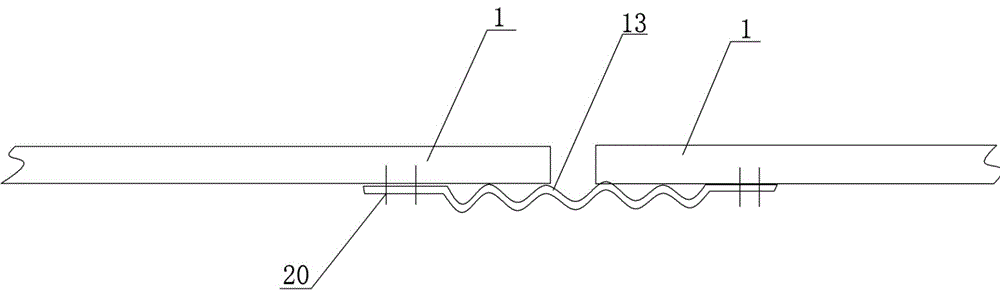

[0025] see figure 2 , the anti-seepage layer of the rubber panel is composed of a plurality of strip-shaped rubber panels adjacent to each other, and the middle expansion joint is arranged at the joint of the butt joint of the adjacent rubber panels;...

Embodiment 2

[0028] Embodiment 2: A construction method of a rubber face rockfill dam, comprising the main structure of the rockfill dam, after the cushion is laid on the surface of the transition zone of the main body of the rockfill dam, on the surface of the transition zone on the water-facing surface of the main body of the rockfill dam, on the compacted and leveled cushion after rolling Pave the anti-seepage layer of the rubber panel; the cushion layer includes a layer of dry stone layer and a layer of foam board layer, the dry stone layer is laid on the surface of the transition zone and compacted, the foam board layer is laid on the surface of the dry layer, and the rubber The anti-seepage layer of the panel is laid and fixed on the surface of the foam board layer; the anti-seepage layer of the rubber panel is composed of a plurality of adjacent rubber panels, and a wrinkled rubber expansion joint 13 is arranged at the butt joint of the adjacent rubber panels. Both ends of the corrug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com