Construction method of bare concrete prefabricated box beam with complicated structure

A fair-faced concrete and box girder construction technology, applied in truss-type structures, joists, girders, etc., to save resources, change traditional concepts, and simplify construction steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

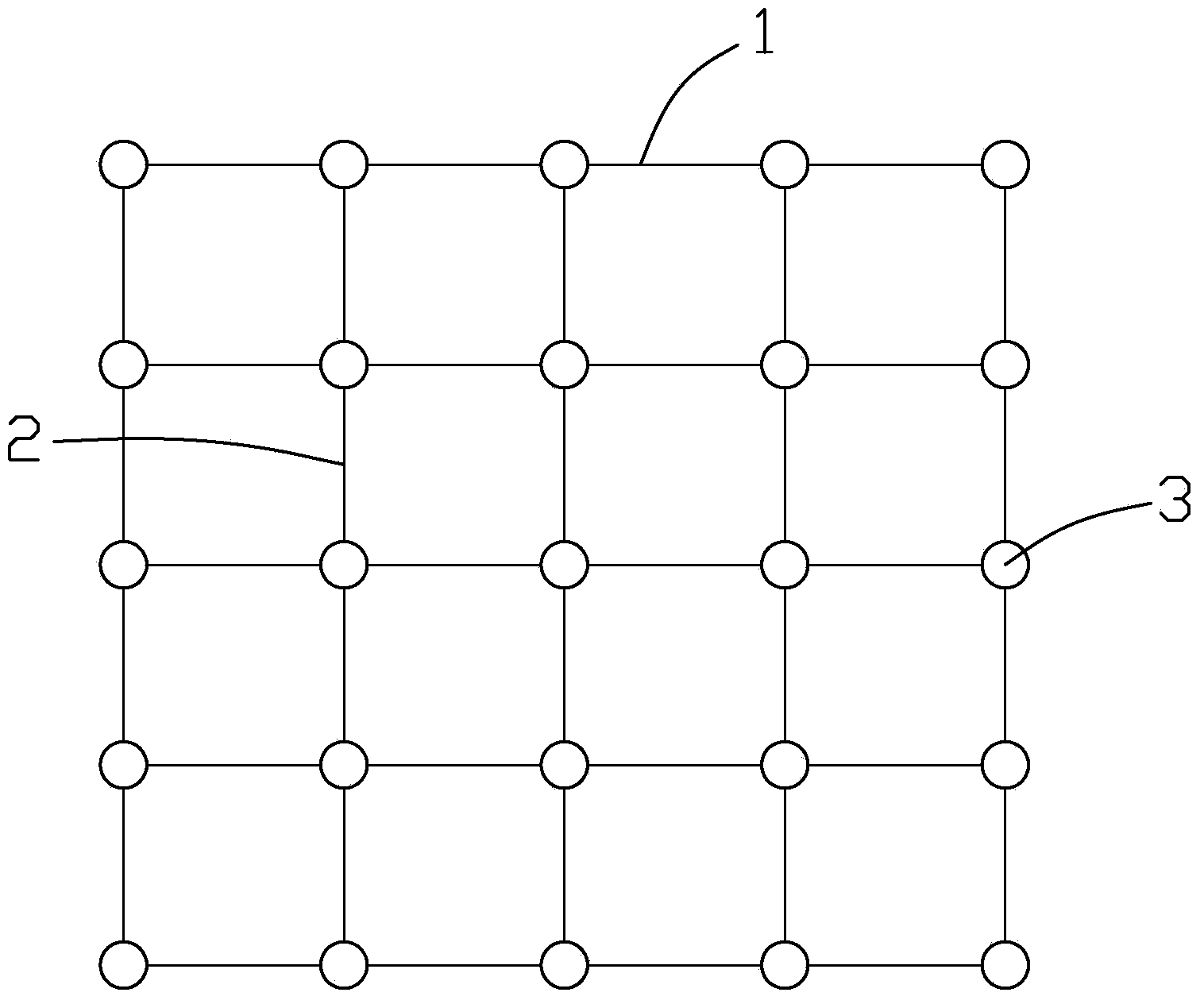

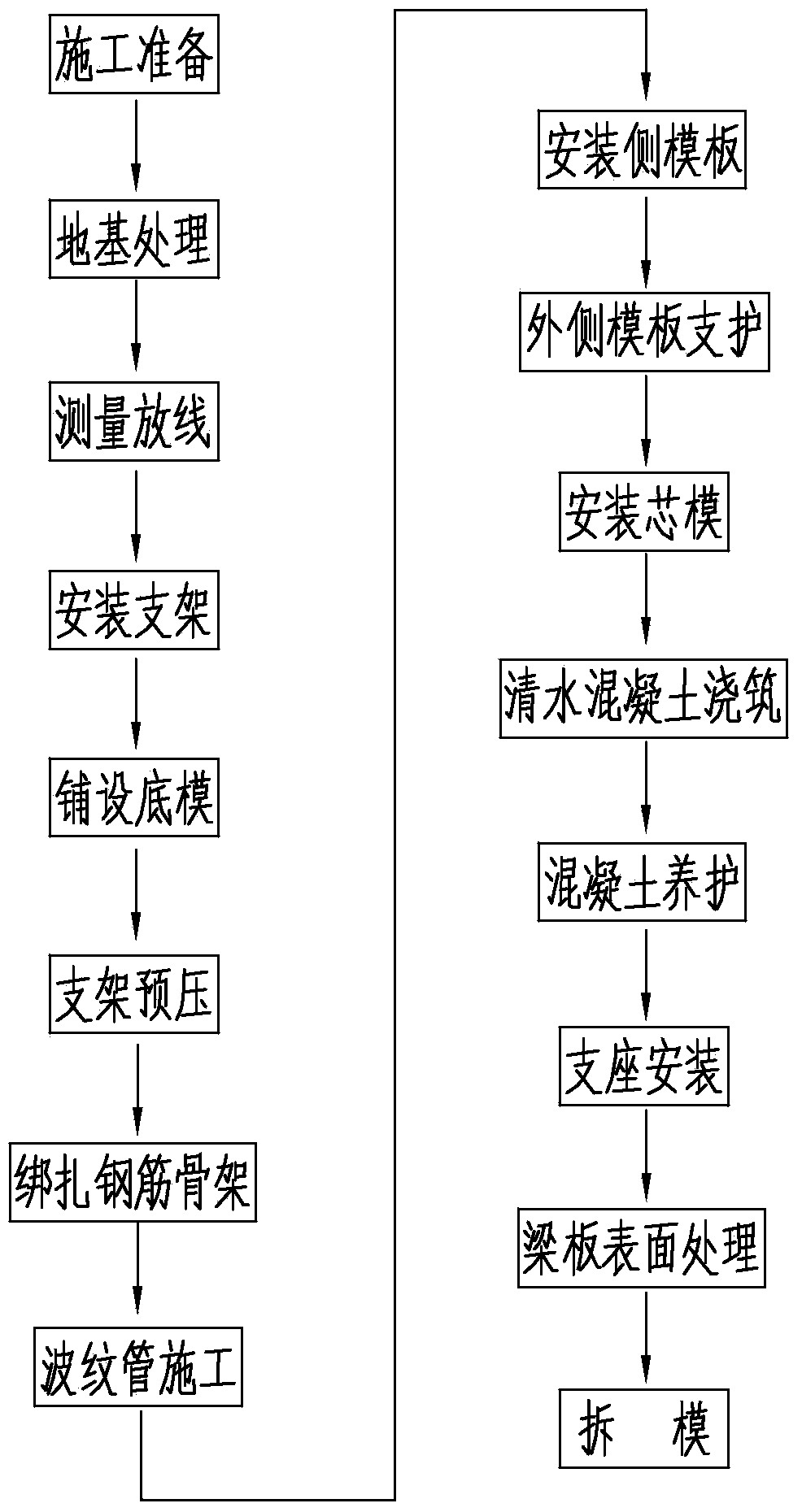

[0051] The present invention is a construction method of complex structure clear-faced concrete prefabricated box girder. By organizing and managing the concrete building structure, on the basis of ensuring the structural performance, the size deviation and appearance quality defects of the concrete structure are reduced as far as possible, and the effect of smooth concrete surface is achieved.

[0052] The inventive method needs to prepare following material:

[0053] 1. Ordinary Portland cement, coarse aggregate, gravel with mud content ≤ 1.0%, fine aggregate, admixture and defoamer.

[0054] 2. Machinery and equipment: Concrete delivery pumps, pump pipes, air compressors, flat vibrators, vibrators, concrete transport vehicles, bucket trucks, hoppers, steel rulers, levels, total stations, theodolites.

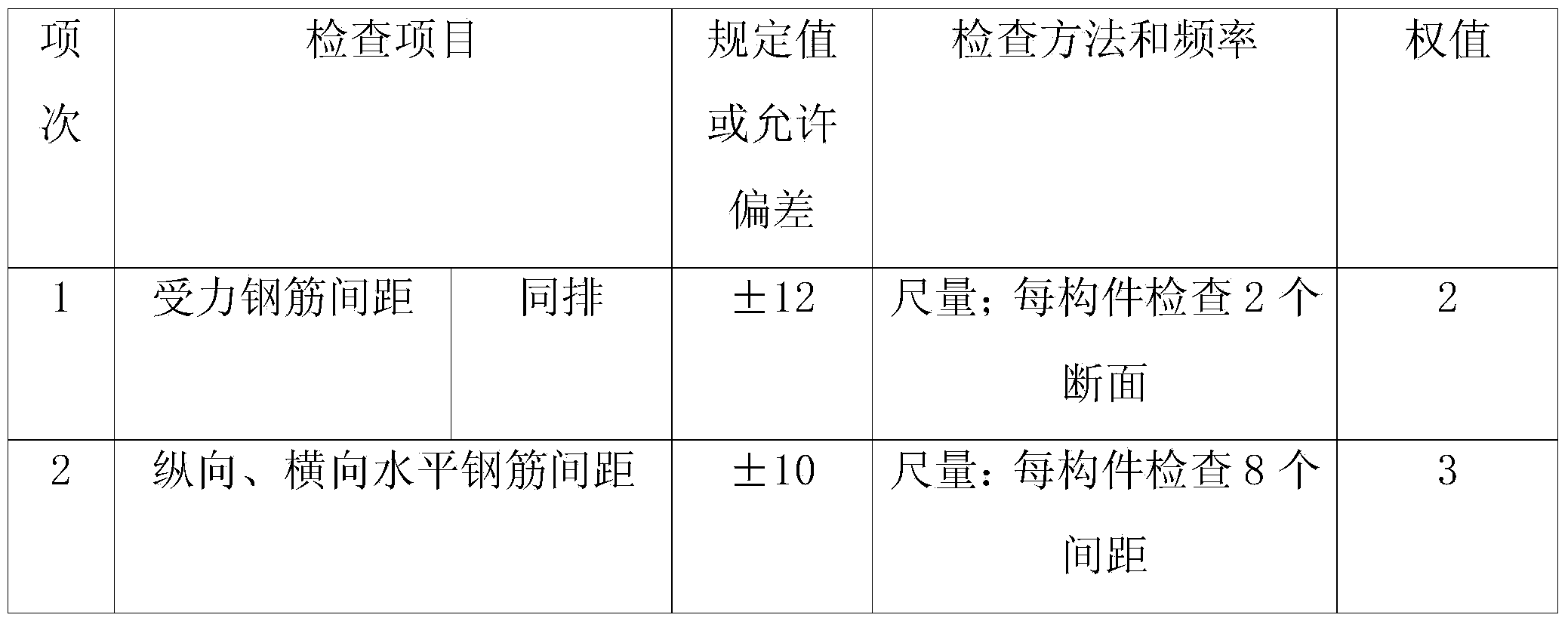

[0055] 3, technical parameter of the present invention (as shown in table 1):

[0056] project

Allowable deviation (mm)

Box girder width

±4

Box...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com