Composite rubber sleeve device

A technology of composite glue and rubber cylinder, which is applied in wellbore/well components, earthwork drilling, sealing/packing, etc. The sealing effect is safe, reliable and easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention is not limited by the following examples, and specific implementation methods can be determined according to the technical solutions of the present invention and actual conditions.

[0017] In the present invention, for the convenience of description, the description of the relative positional relationship of each component is based on the description attached to the description. figure 1 For example, the positional relationship of front, back, up, down, left, right, etc. is based on the attached figure 1 determined by the layout direction.

[0018] Below in conjunction with embodiment and accompanying drawing, the present invention will be further described:

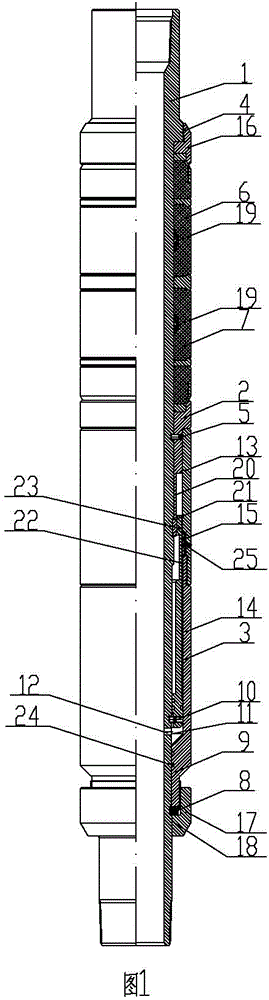

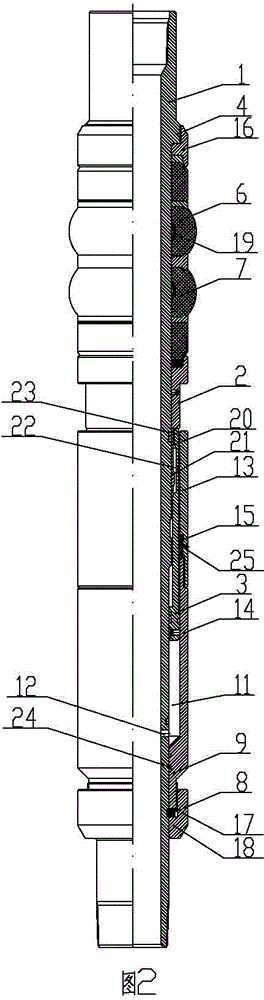

[0019] as attached figure 1 , 2 As shown, the composite rubber cartridge device includes a central rod 1, claw sleeves 2, sleeves and push cylinders 3; an upper card platform 4 is fixed outside the upper end of the central rod 1, and a first shear nail is passed outside the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com