Measurement method for effective extraction radius of drill hole

A technology of drainage radius and measurement method, which is applied to earthwork drilling, measurement, mining equipment, etc., can solve the problems of attenuation of gas leakage pressure value in pressure measurement drilling holes, difficulty in measuring gas pressure, etc., so as to reduce the difficulty of measurement and improve The effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

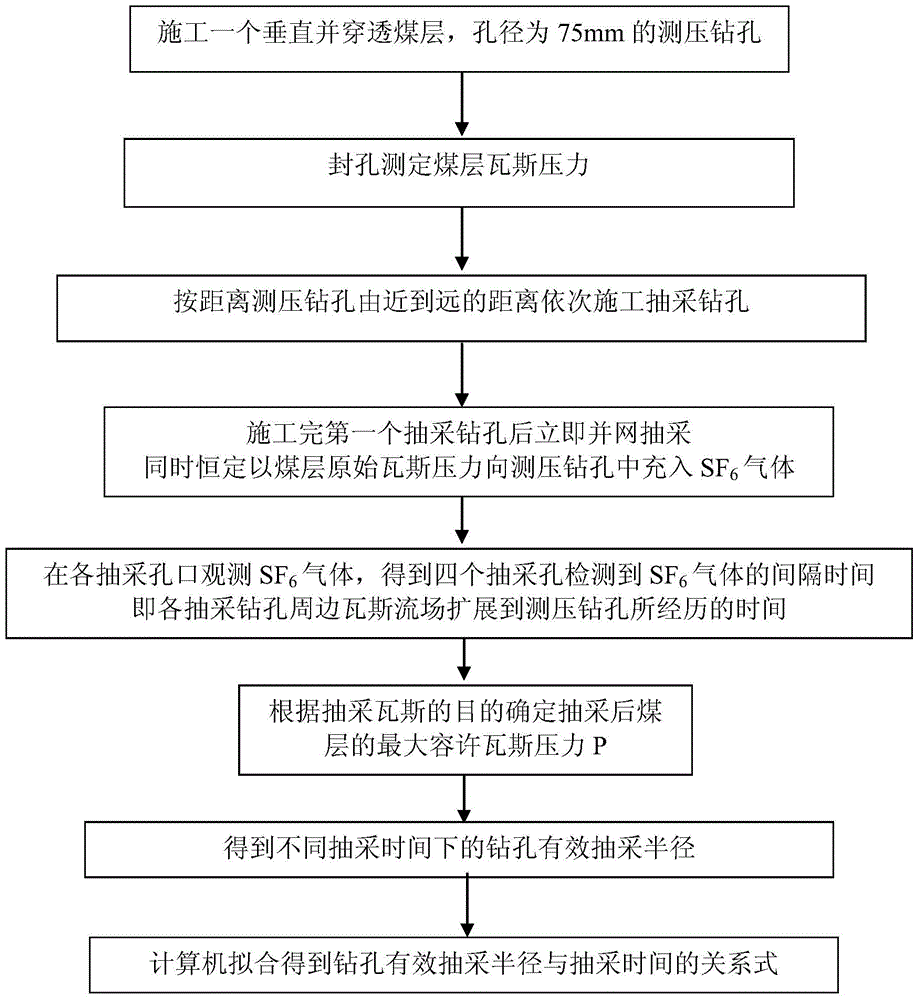

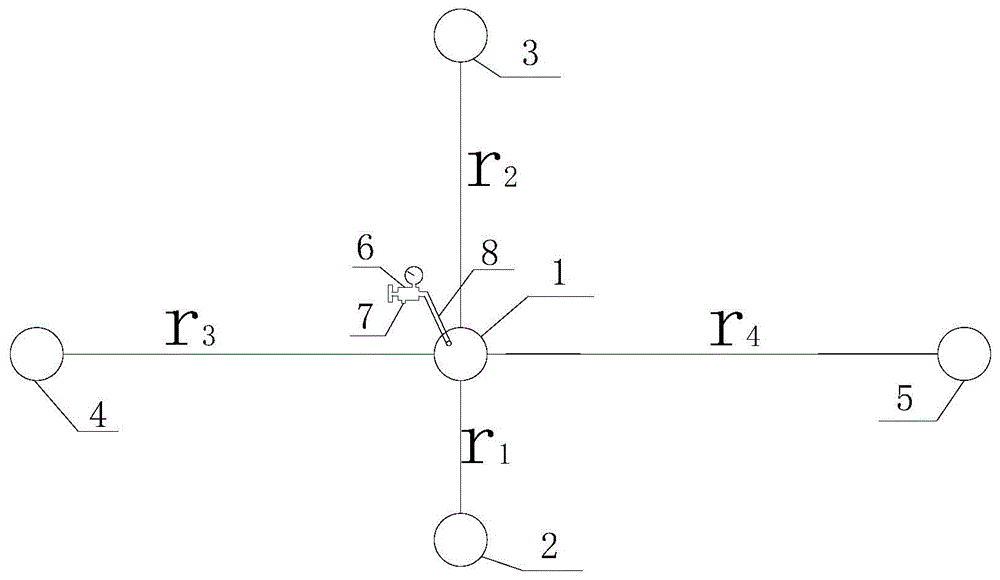

[0019] The method for measuring the effective drainage radius of the borehole based on the radial stable flow field of the present invention is to measure the gas pressure of the coal seam by constructing a borehole perpendicular to the coal seam underground in the coal mine, and to measure the gas pressure of the coal seam by constructing four parallel gas drains around the borehole. Drain the borehole, and then fill the pressure measurement borehole with SF at the original gas pressure of the coal seam 6 Gas, create the measurement conditions of radial stable flow field, record the observation of SF under different spacing conditions between the drainage observation hole and the gas filling hole 6 Determine the extension range of different gas flow fields and the corresponding time; and determine the effective drainage radius at different times according ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com