Treatment and flow control method for gas compressor casing with scattered seam type circumferential grooves

A casing processing and flow control technology, applied in the direction of machines/engines, mechanical equipment, engine functions, etc., can solve problems affecting the stable working range of the compressor, strong vibration, performance deterioration, etc., to improve the stable working range and improve Blade tip flow field and the effect of increasing stall margin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

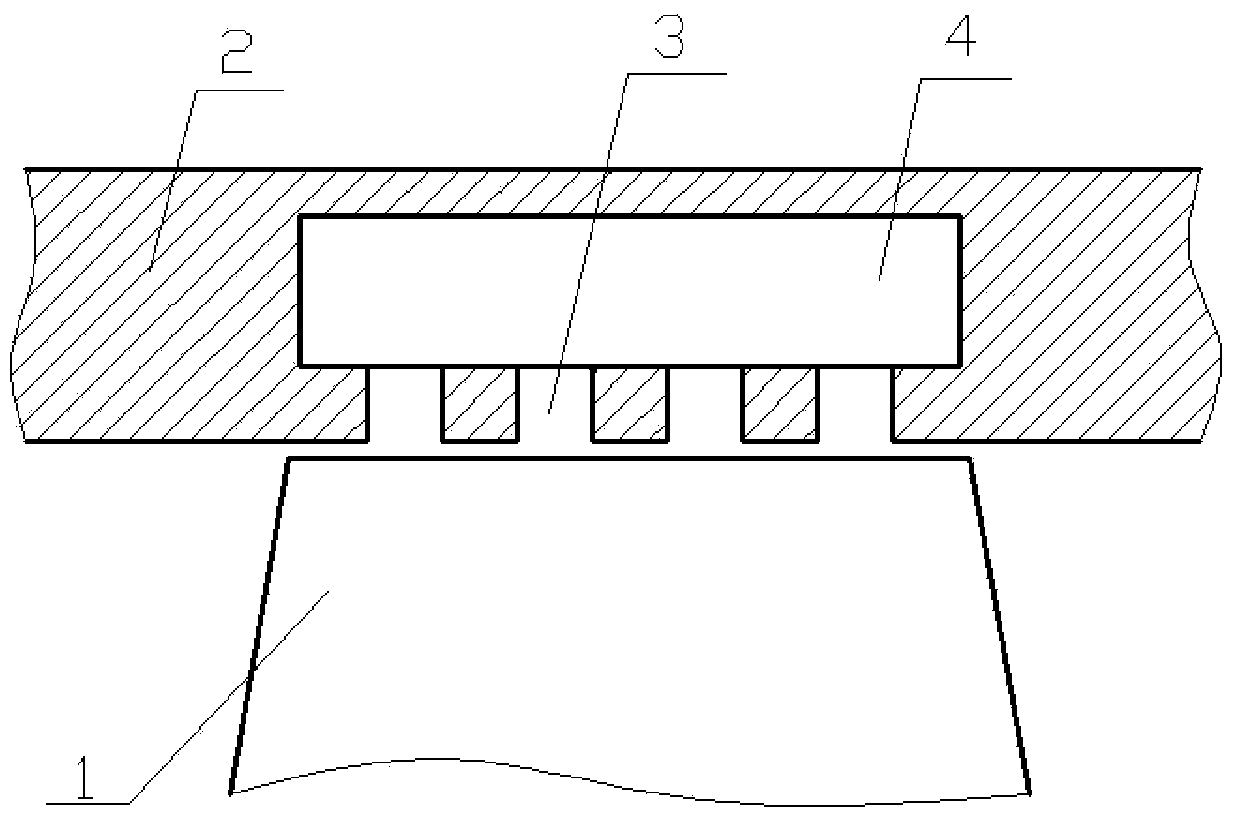

[0024] The compressor device aimed at by the present invention is made up of compressor motor vane 1, compressor casing 2, circumferential groove 3 and discrete seam 4, as Figure 1a~1c shown. The rotating blades add work to the airflow flowing through the compressor, increasing the pressure of the airflow. Under certain speed conditions, when the gas flow through the compressor decreases to a certain extent, the compressor will experience instability. The casing with discrete slit circumferential slots improves the stable operating range of the compressor by controlling the flow field at the top of the compressor blade.

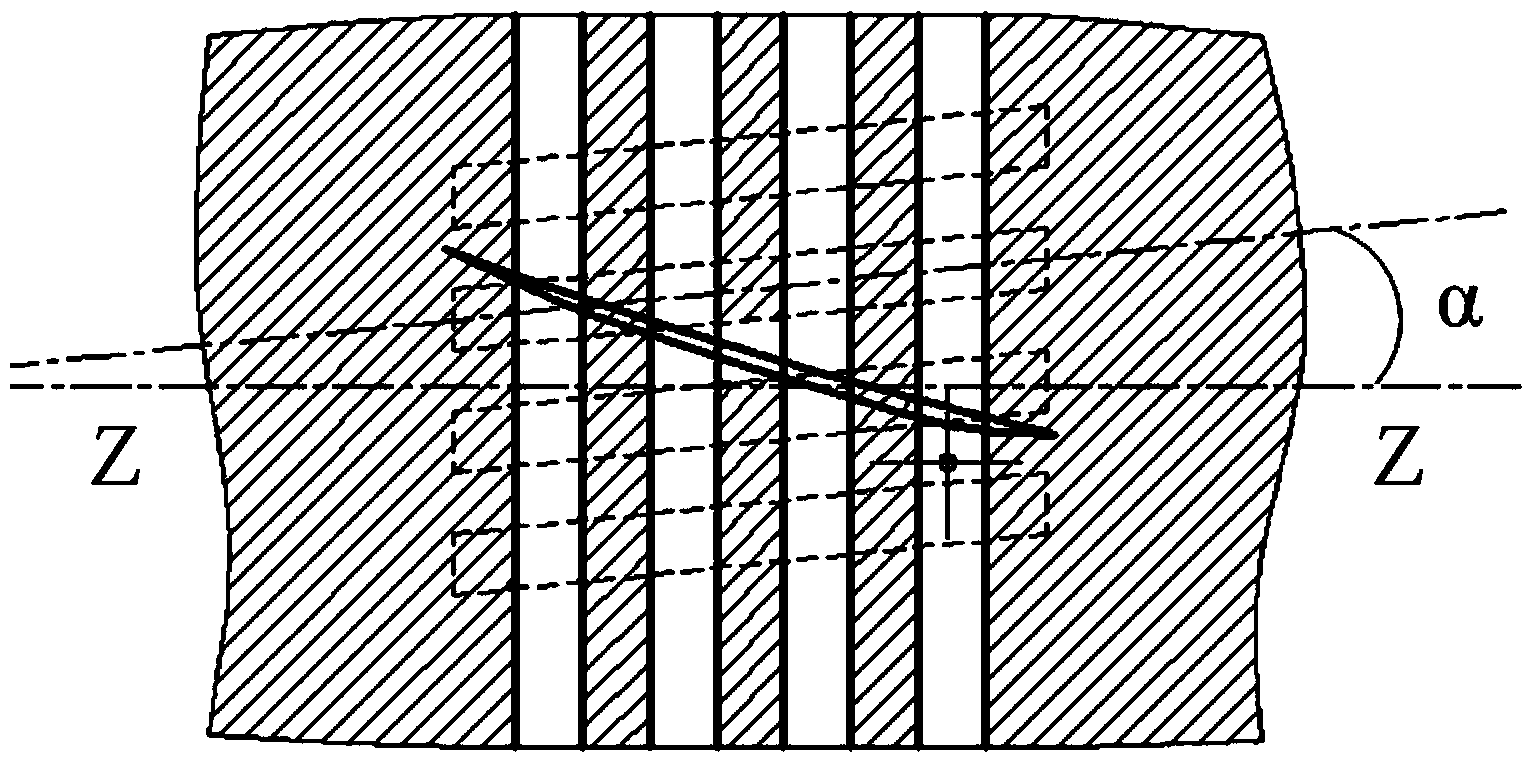

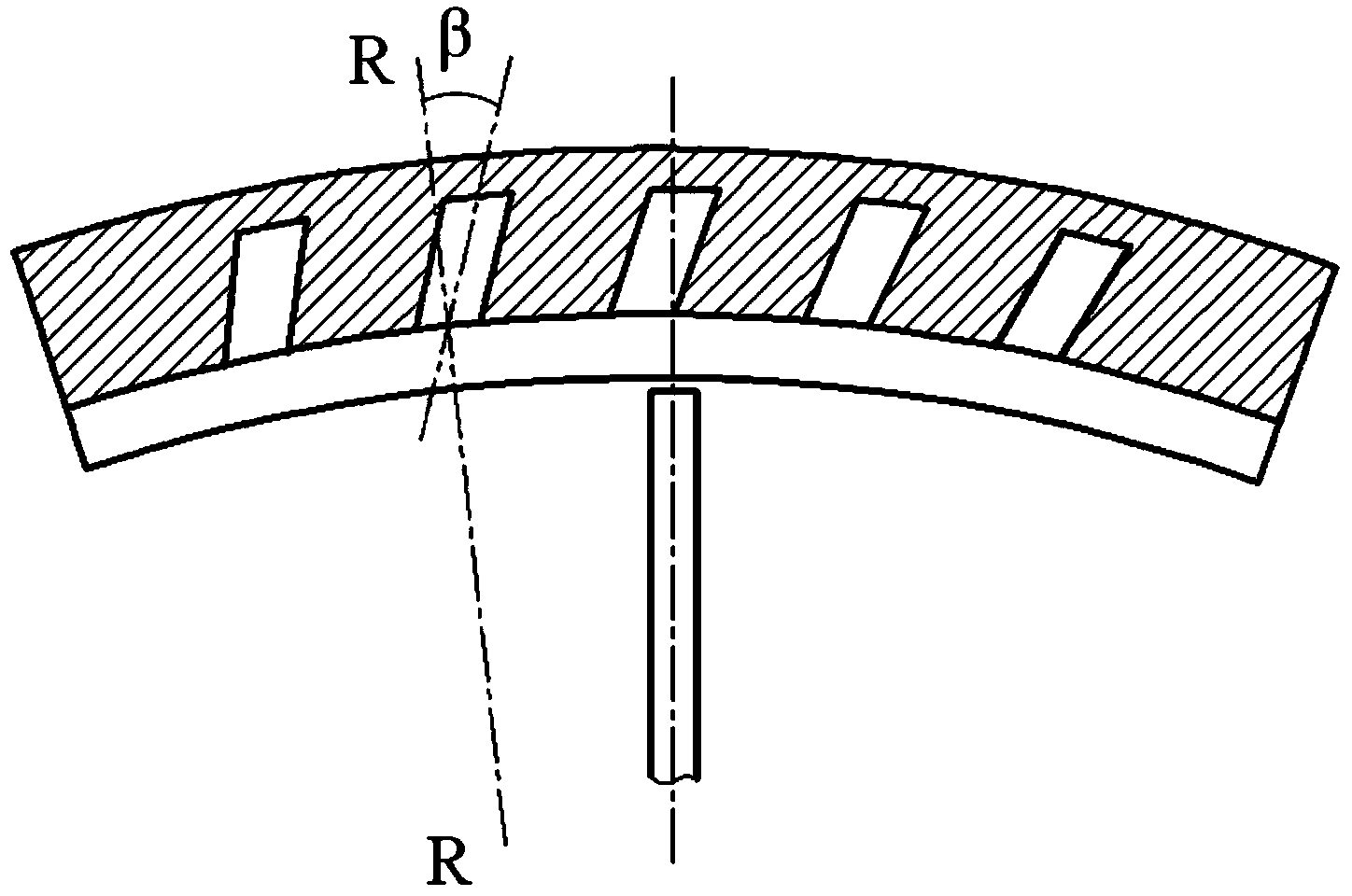

[0025] The case processing structure with discrete slit type circumferential slots is composed of circumferential slots 3 and disc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com