Parallel-connection liquid-electricity feed suspension system

A suspension system, parallel technology, applied in the field of vehicle suspension system, can solve problems such as unfavorable vehicle ride comfort control, difficulty in realizing separate adjustment, etc., to improve handling stability and driving comfort, stabilize generator speed, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

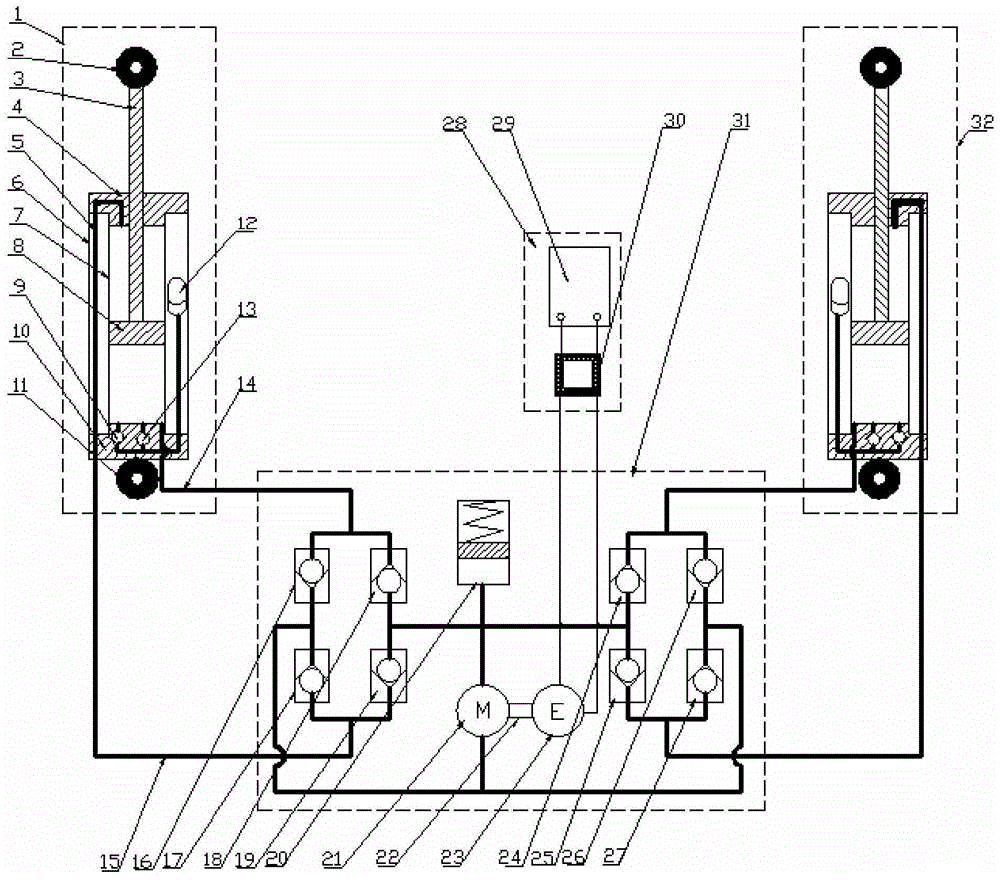

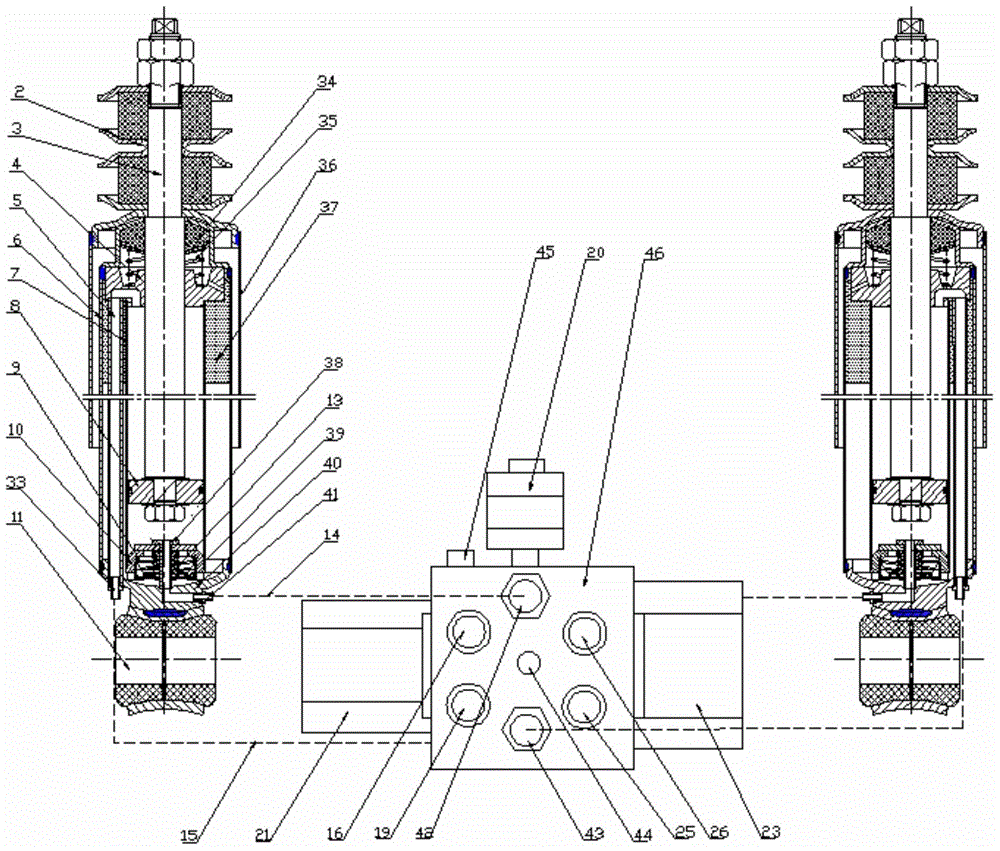

[0026] Embodiment 1. A parallel hydraulic-electric energy-feeding suspension system

[0027] The parallel hydraulic electric energy feed suspension system provided by this embodiment 1 is a kind of suspension system such as figure 1 and figure 2 The structure shown is composed of two hydraulic cylinder modules with the characteristics of two-way cylindrical shock absorbers connected in parallel to a hydraulic-electric energy conversion module with the characteristics of a complete rectifier bridge. The external oil pipe 14 of the rod cavity is matched and connected.

[0028] The first hydraulic cylinder module 1 is transformed from a two-way cylinder shock absorber. The hydraulic cylinder module consists of a piston push rod hinge 2, a piston push rod 3, a guide 4, an extension stroke pipeline 5, Oil storage cylinder 6, working cylinder 7, piston 8, compensation valve 9, compression valve seat 10, cylinder body hinge 11, compression valve 13, oil pipe flange with rod cavity...

Embodiment 2

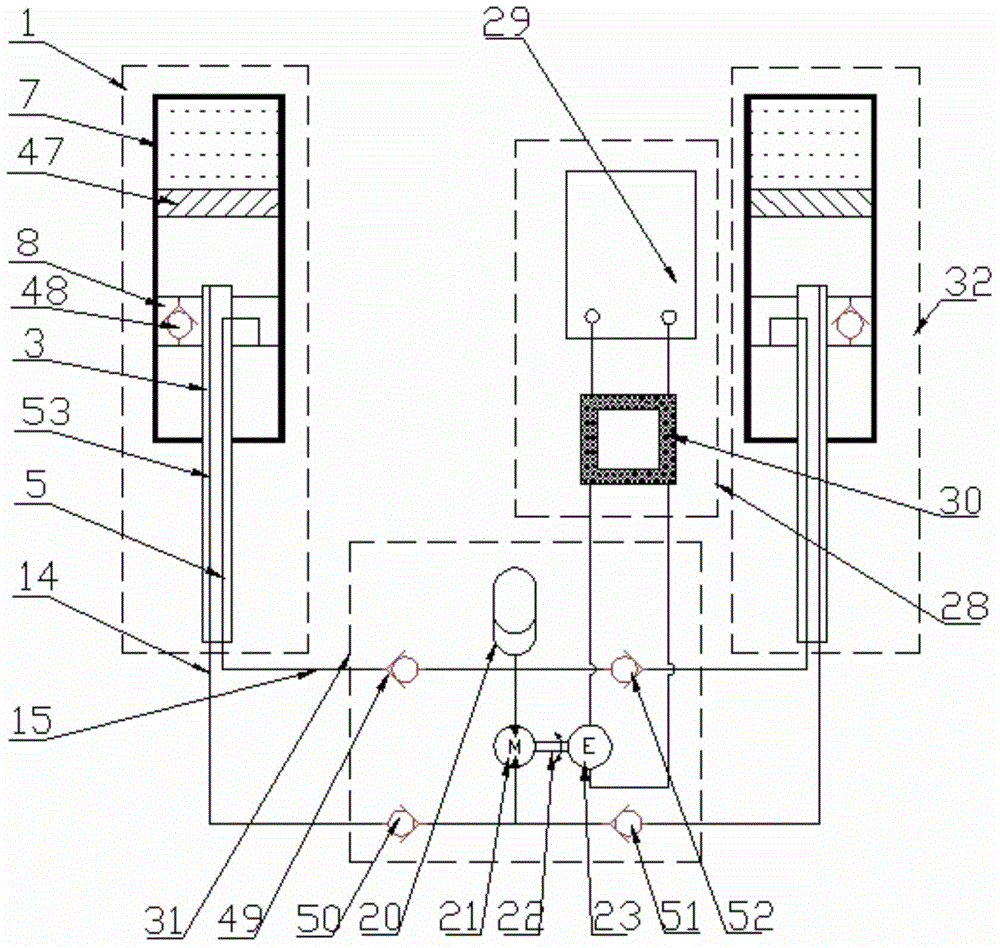

[0031] Embodiment 2. The second parallel hydraulic electric energy feed suspension system

[0032] The parallel hydraulic electric energy feed suspension system provided by this embodiment 2 is a kind of suspension system such as image 3 and Figure 4 The shown structure consists of two hydraulic cylinder modules with the characteristics of a single-tube oil-pneumatic shock absorber connected in parallel to a hydraulic-electric energy conversion module with the characteristics of a partial rectifier bridge. The two modules are externally connected to the oil pipe 15 and The external oil pipe 14 of the rodless cavity is matched and connected.

[0033] The first hydraulic cylinder module 1 is transformed from a single-tube oil-gas shock absorber. The hydraulic cylinder module consists of a piston push rod 3, an extension stroke pipeline 5, a working cylinder 7, a piston 8, a floating piston 47. The piston compression valve 48 is composed of a compression stroke pipeline 53, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com