Single sensor mechanical structure for weighing

A mechanical structure and sensor technology, applied in the field of sensors, can solve the problems of low weighing accuracy, poor stability and reliability, and high price, and achieve the effects of improving measurement resolution, small invalid travel, and good stability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

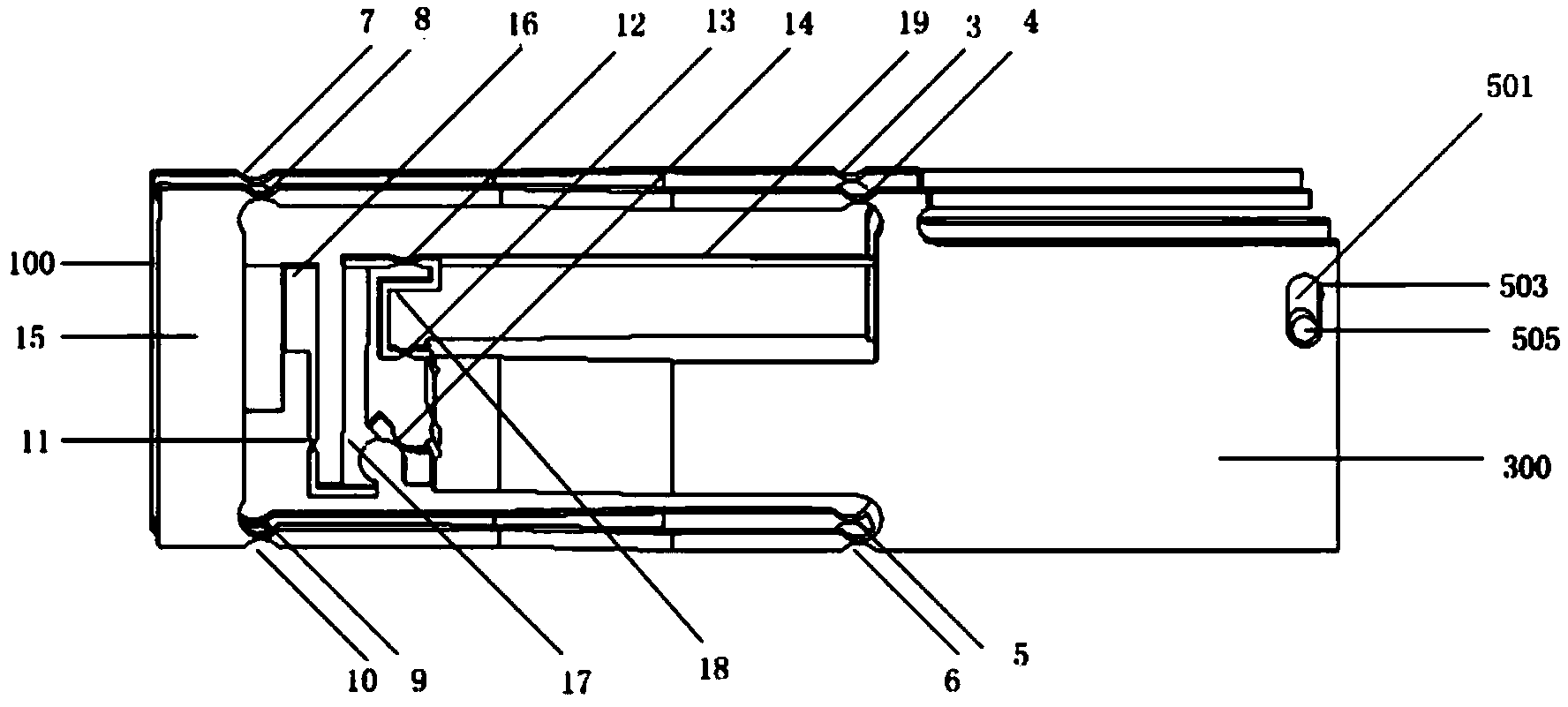

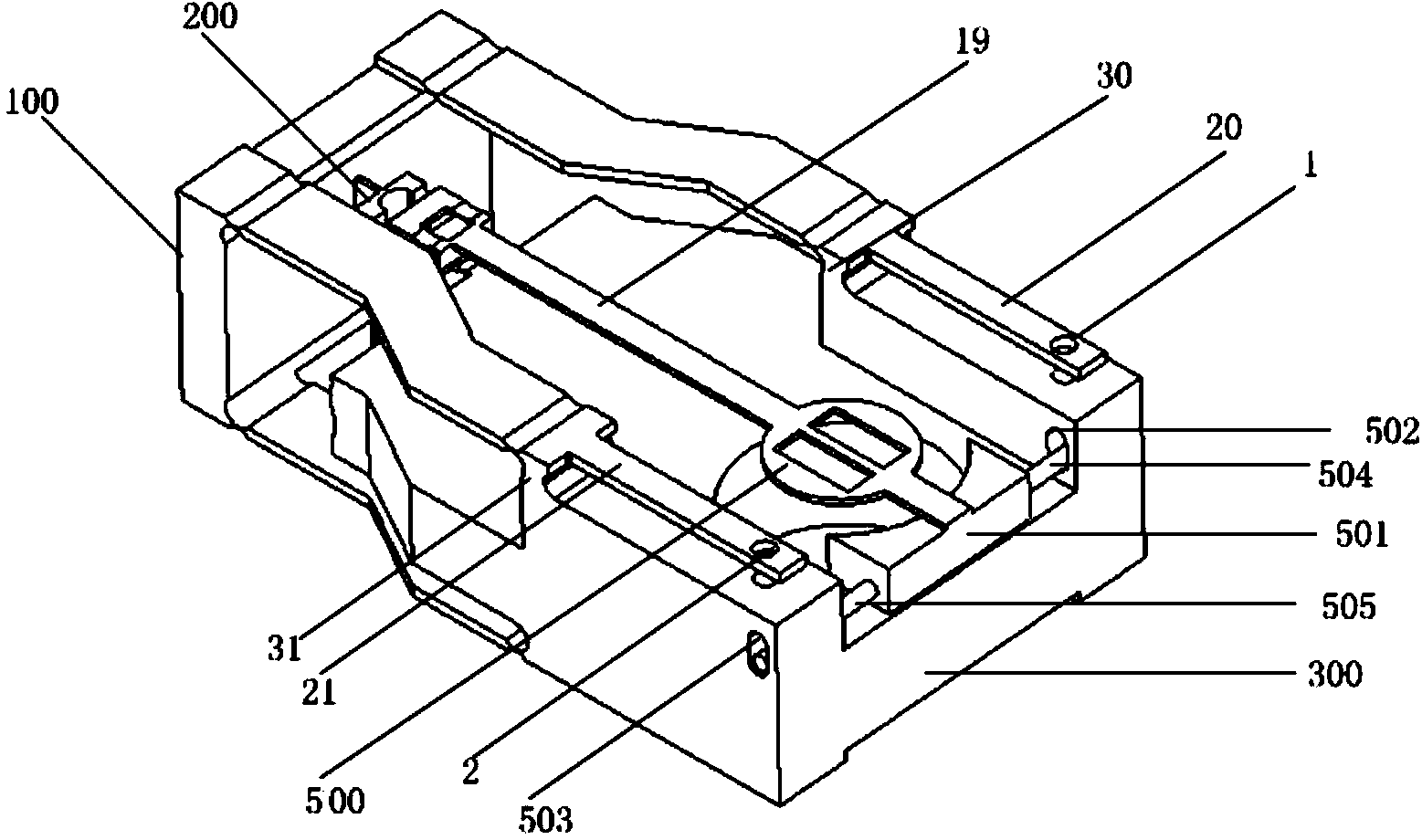

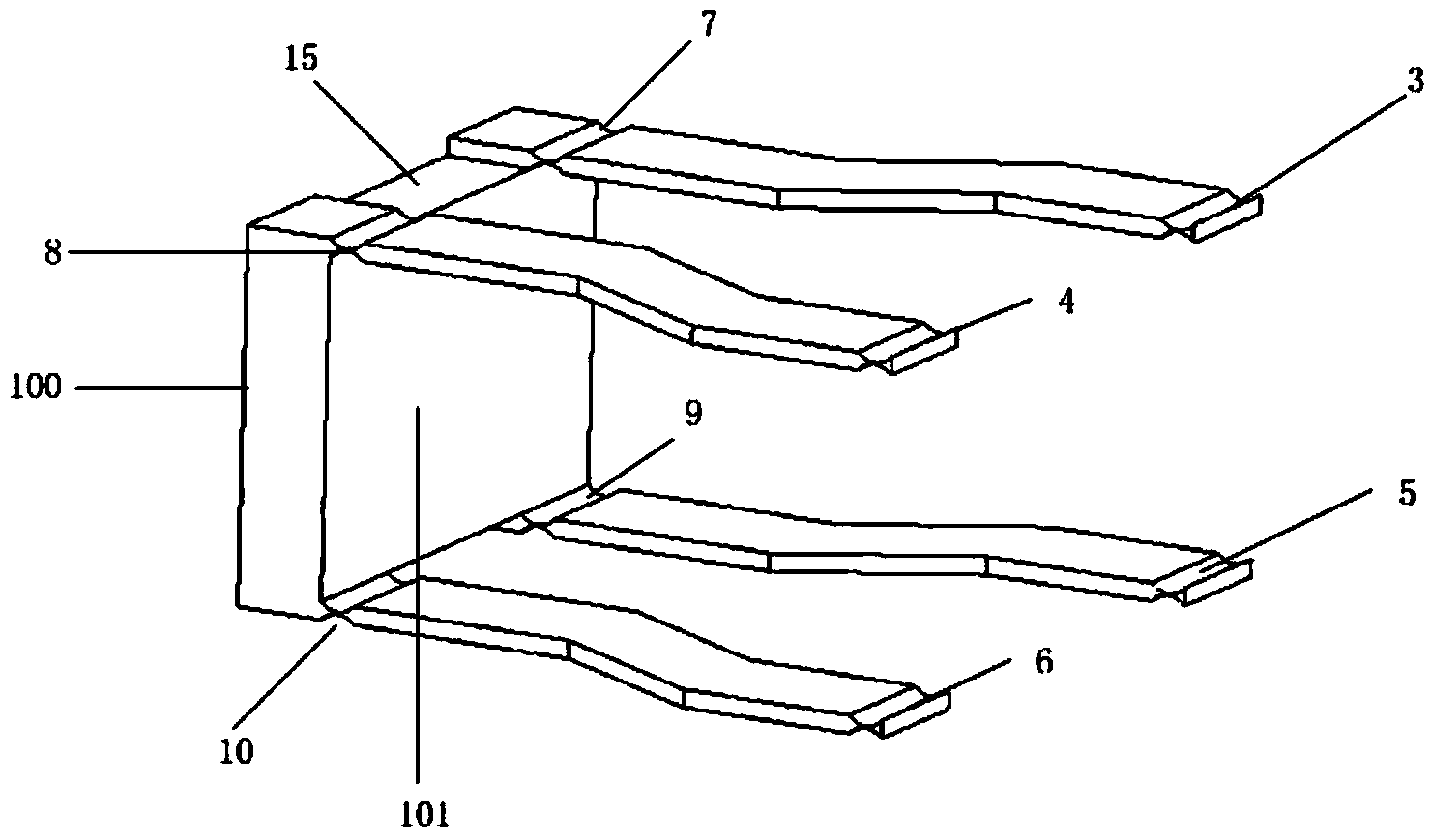

[0017] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0018] The Roberville mechanism is a positive parallelogram linkage mechanism, and its main function is to eliminate the error caused to the weighing result when the weight is eccentrically loaded. The displacement mechanism converts the vertical downward force into the displacement corresponding to the force. The flexible hinge is formed with grooves of arcs with a radius of R on two opposite surfaces of a rectangular cube respectively. The flexible hinge mechanism utilizes the micro-deformation and automatic recovery characteristics of elastic materials, eliminates the lost motion and mechanical friction in the transmission process, and can obtain ultra-high displacement resolution.

[0019] Such as Figure 1 to Figure 5 As shown, a single sensor mechanical structure for weighing, the single sensor mechanical structure is integrally formed w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com