A Method for Sensitivity Analysis of Machining Accuracy Reliability of CNC Machine Tool

A technology of sensitivity analysis and machining accuracy, applied in program control, computer control, general control system, etc., can solve problems such as difficulty in obtaining satisfactory results

- Summary

- Abstract

- Description

- Claims

- Application Information

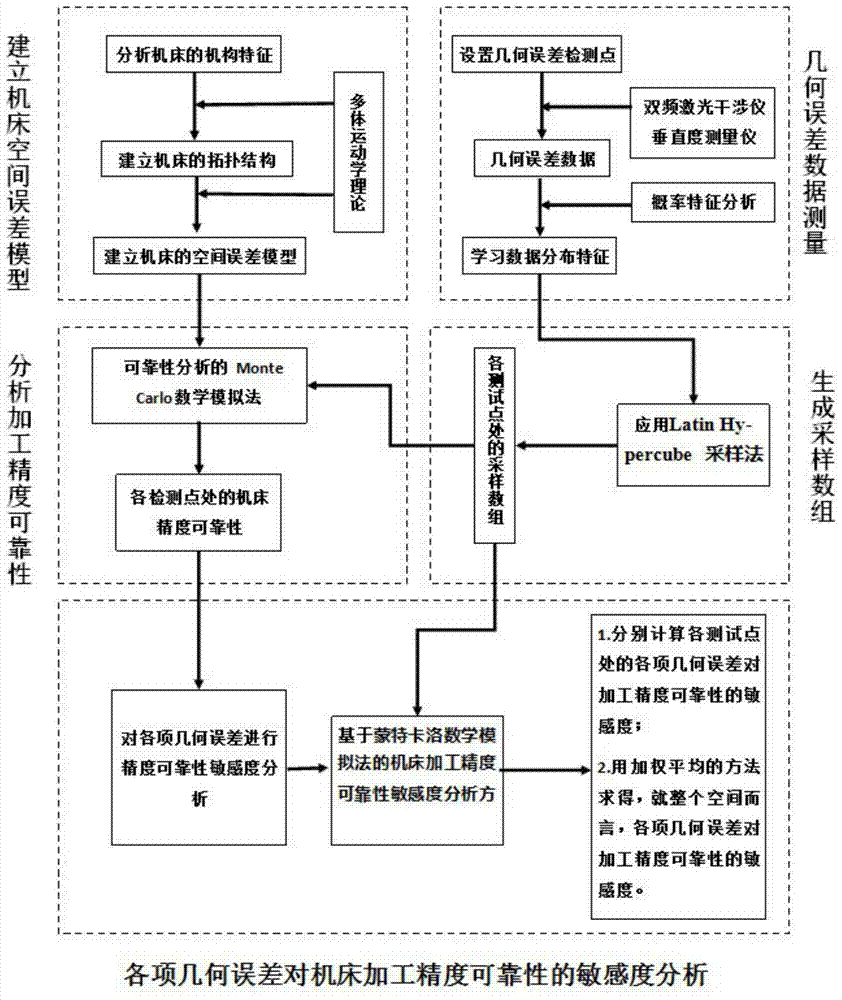

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

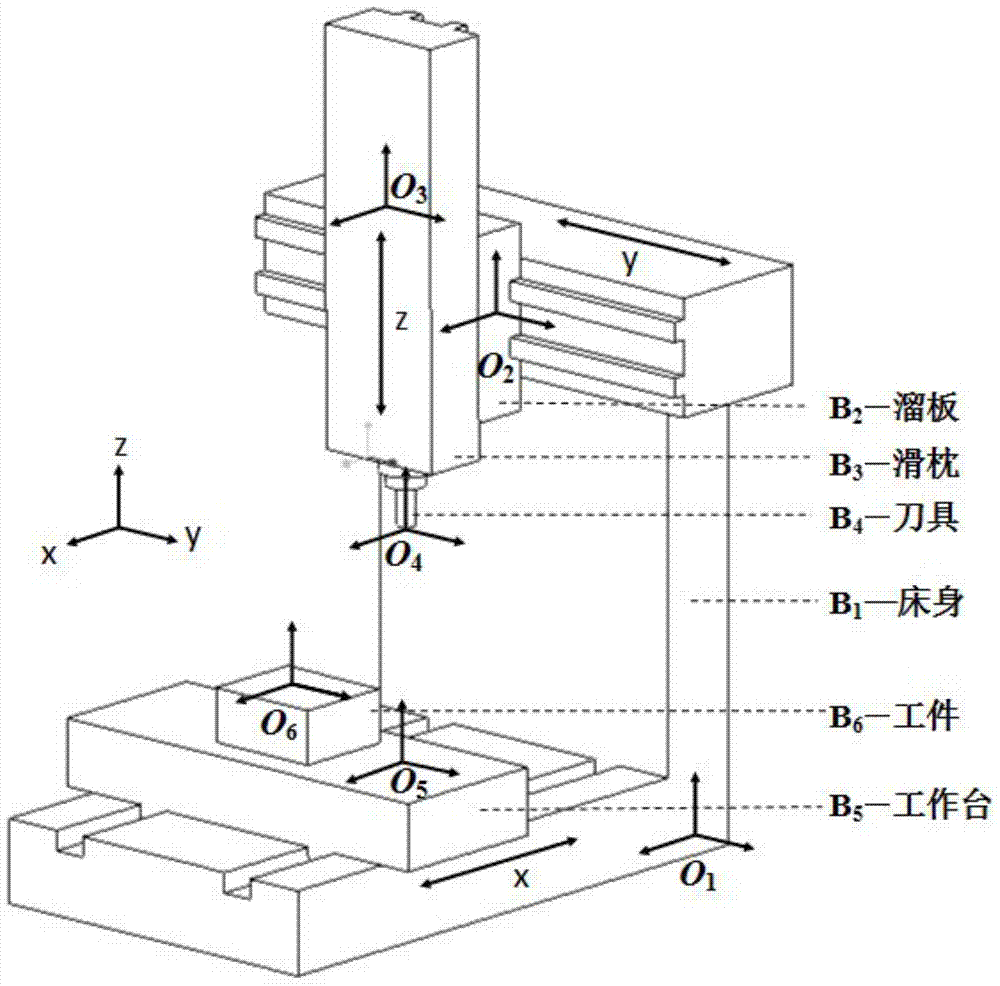

[0154] The present invention takes a three-axis precision vertical machining center as an example to verify the above-mentioned numerical control machine tool machining accuracy reliability sensitivity analysis method.

[0155] Specifically include the following steps:

[0156] Step 1 Set up the generalized coordinate system for the three-axis machine tool, and establish the spatial error model of the machine tool.

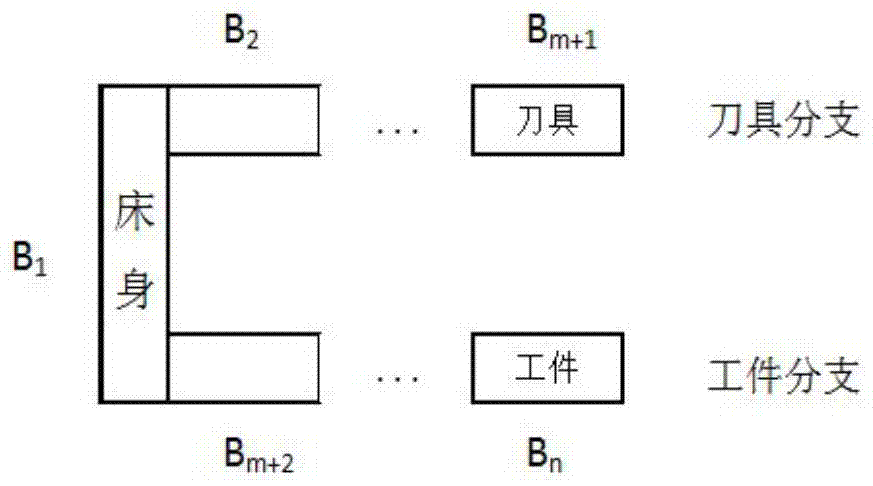

[0157] Based on the multi-body system kinematics theory, low-order body arrays are used to describe the topology of the abstract machine tool system, a generalized coordinate system is established in the multi-body system, positional relationships are expressed by vectors and their column vectors, and multi-body is represented by a homogeneous coordinate transformation matrix interrelationships between systems;

[0158] Step 1.1 Establish the topology of the three-axis machine tool

[0159] The structure of the machine is as image 3 shown. The machine tool in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com