Axial flow fan propeller

A fan impeller, axial flow technology, used in mechanical equipment, non-variable capacity pumps, machines/engines, etc., can solve the problems of difficult drafting, high cost of precision casting molds, and difficult replacement, and achieve reliability and processing. The effect of improving accuracy, reducing production costs and extending service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

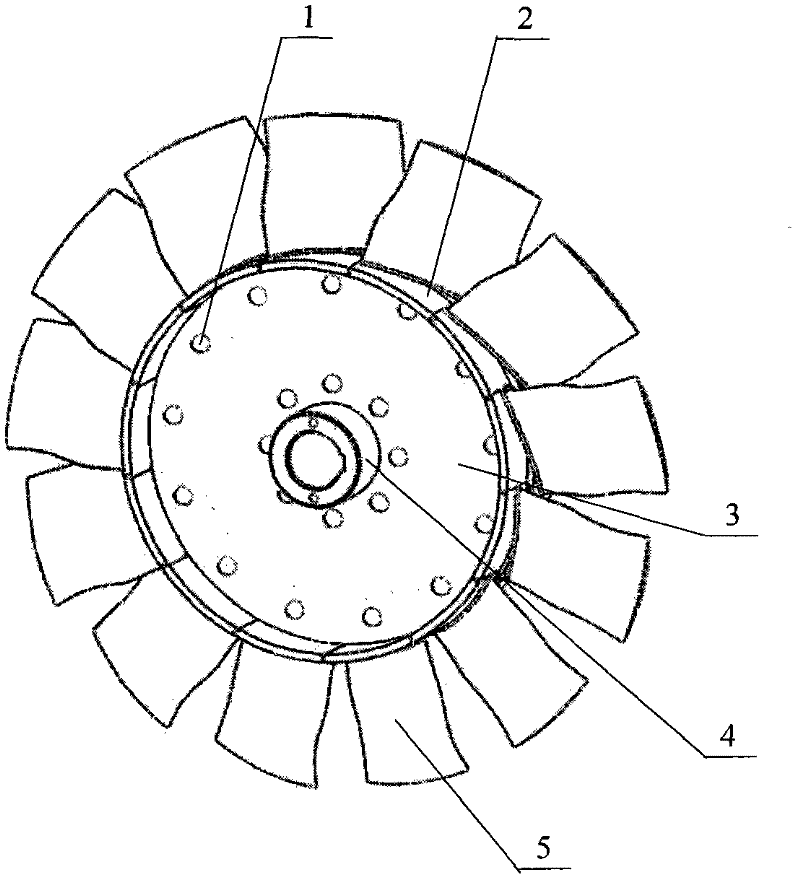

[0016] This embodiment is an axial flow fan impeller.

[0017] This embodiment includes a blade disc 2 , a spoke disc 3 , a hub 4 , a blade 5 and a petiole 8 .

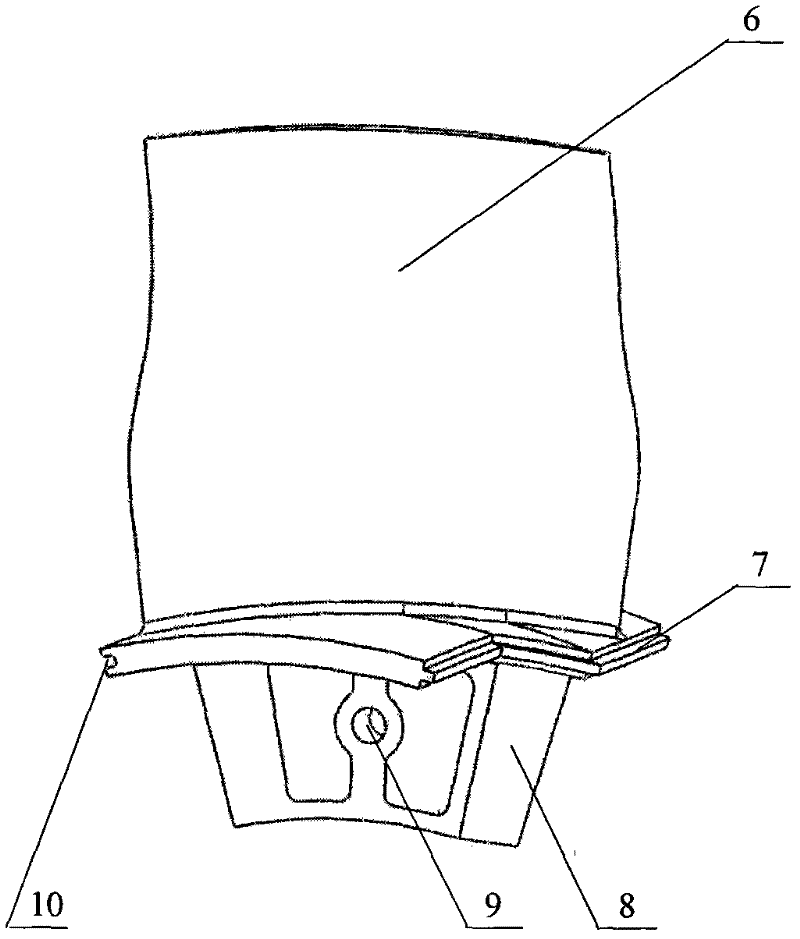

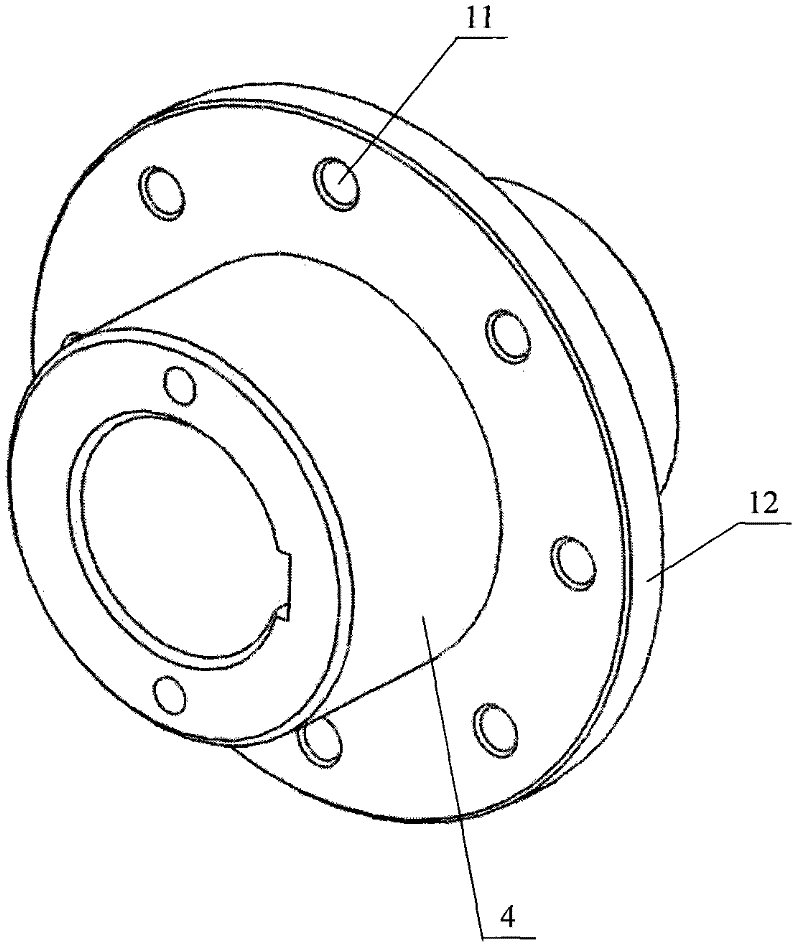

[0018] The blade flap 6 is composed of the blade 5, the tenon 7, the petiole 8, the connecting hole 9 and the tenon and groove 10, and is integrally cast with aluminum alloy. There is a radially protruding petiole mounting plate 12 in the middle of the hub 4 ; the blade 5 is fixed on the petiole mounting plate 12 of the hub 4 through the petiole 8 . The two spoke discs 3 are set on the two ends of the petiole mounting disc 12 on the hub 4 and fixed by bolts 1 . The blade wheel disc 2 is sleeved on the hub 4 . The blade wheel 2 is formed by splicing 13 blade wheel petals 6 . There are tenons 7 and tenon grooves 10 on both sides of the blade wheel disc 6, and the tenon 7 on each blade wheel disc 6 is embedded in the tenon 10 on the other adjacent blade wheel disc 6. Inside, a complete cylindrical blade wheel disc 2 ...

Embodiment 2

[0022] This embodiment is an axial flow fan impeller.

[0023] This embodiment includes a blade disc 2 , a spoke disc 3 , a hub 4 , a blade 5 and a petiole 8 .

[0024] The blade flap 6 is composed of the blade 5, the tenon 7, the petiole 8, the connecting hole 9 and the tenon and groove 10, and is integrally cast by engineering plastic nylon. There is a radially protruding petiole mounting plate 12 in the middle of the hub 4 ; the blade 5 is fixed on the petiole mounting plate 12 of the hub 4 through the petiole 8 . The two spoke discs 3 are set on the two ends of the petiole mounting disc 12 on the hub 4 and fixed by bolts 1 . The blade wheel disc 2 is sleeved on the hub 4 . The blade wheel disc 2 is formed by splicing 18 blade wheel disc petals 6 . There are tenons 7 and tenon grooves 10 on both sides of the blade wheel disc 6, and the tenon 7 on each blade wheel disc 6 is embedded in the tenon 10 on the other adjacent blade wheel disc 6. Inside, a complete cylindrical ...

Embodiment 3

[0028] This embodiment is an axial flow fan impeller.

[0029] This embodiment includes a blade disc 2 , a spoke disc 3 , a hub 4 , a blade 5 and a petiole 8 .

[0030] The blade flap 6 is composed of the blade 5, the tenon 7, the petiole 8, the connecting hole 9 and the tenon and groove 10, and is integrally cast by engineering plastic MPPO. There is a radially protruding petiole mounting plate 12 in the middle of the hub 4 ; the blade 5 is fixed on the petiole mounting plate 12 of the hub 4 through the petiole 8 . The two spoke discs 3 are set on the two ends of the petiole mounting disc 12 on the hub 4 and fixed by bolts 1 . The blade wheel disc 2 is sleeved on the hub 4 . The blade wheel disc 2 is formed by splicing 20 blade wheel disc petals 6 . There are tenons 7 and tenon grooves 10 on both sides of the blade wheel disc 6, and the tenon 7 on each blade wheel disc 6 is embedded in the tenon 10 on the other adjacent blade wheel disc 6. Inside, a complete cylindrical b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com