Electronic system with a composite substrate

A technology for electronic components and electronic devices, applied in circuits, printed circuits, electrical components, etc., to solve problems such as inability to conduct heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

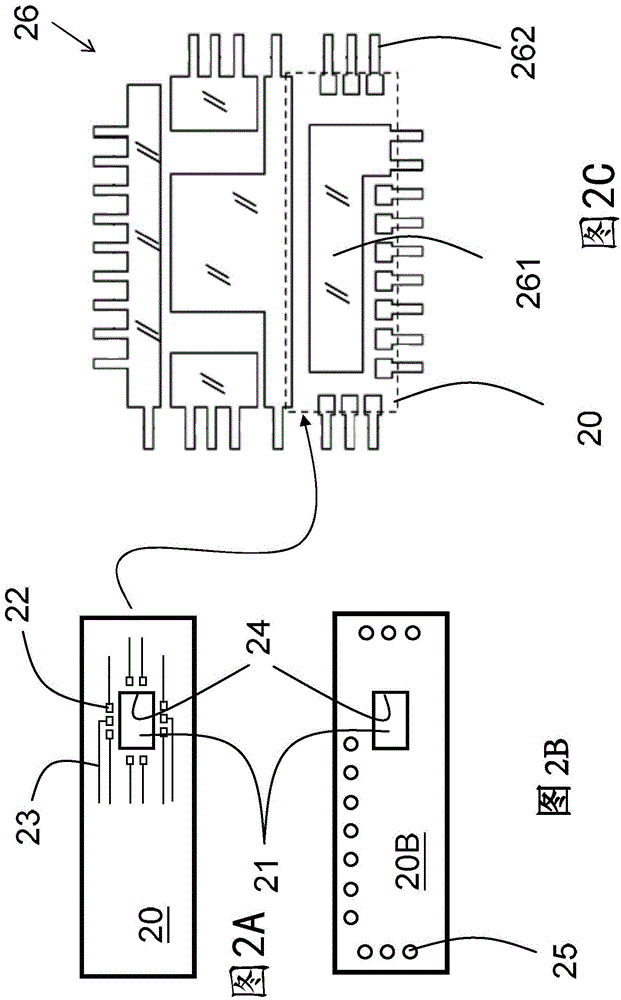

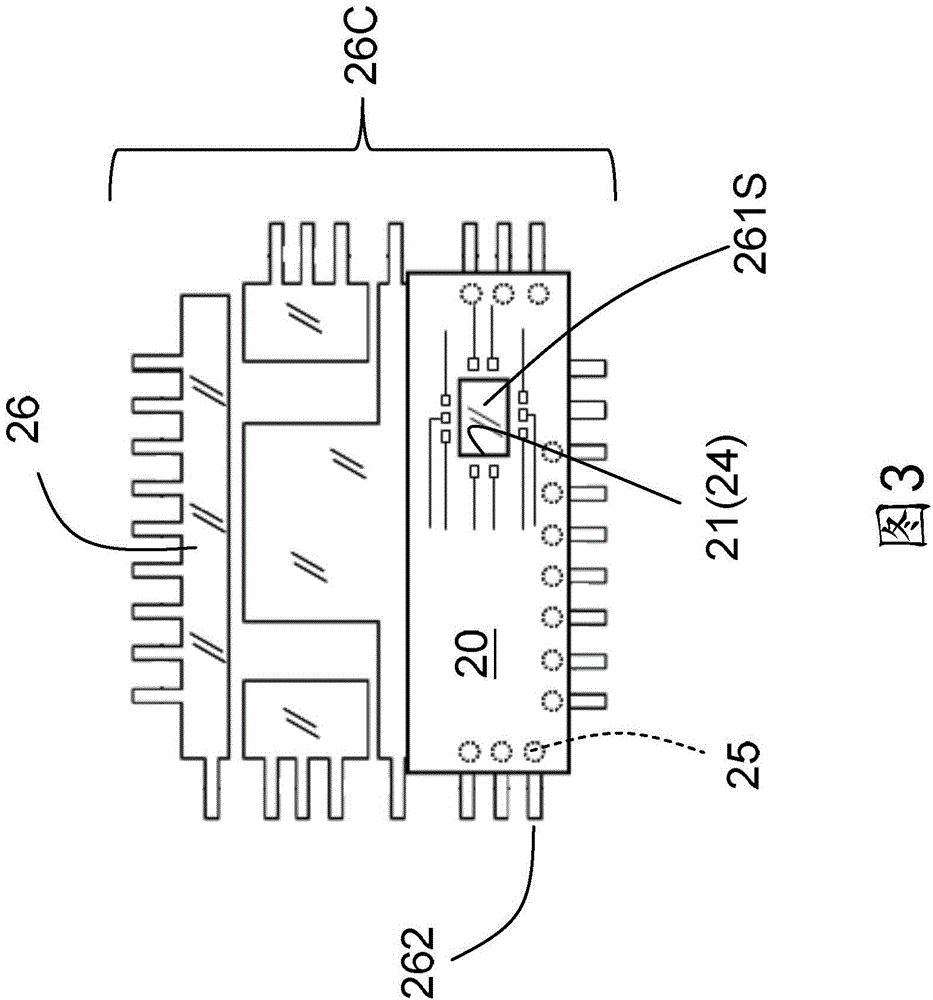

[0059] Such as Figure 2A The display circuit board 20 has a rectangular opening 21 , and a group of metal pads 22 surround four edges 24 of the rectangular opening 21 . The metal pad 22 is a part of the circuit on the circuit board 20 , and the metal pad 22 is electrically coupled to the circuit (not shown) on the circuit board 20 via the metal wire 23 .

[0060] Such as Figure 2B As shown, a set of bottom metal contacts 25 are disposed on the bottom surface 20B of the circuit board 20 , and the metal contacts 25 are subsequently electrically coupled to corresponding metal pins 262 on the circuit board 20 .

[0061] Such as Figure 2C As shown, a metal frame 26 has several large pieces of metal 261, which can carry high-heating electronic components; the metal frame 26 also has a set of peripheral metal feet 262 distributed around the metal frame 26, followed by packaging After packaging, the peripheral metal pins 262 serve as output / input pins of the electronic system. ...

Embodiment 2

[0068] Such as Figure 5A As shown, the edge of the circuit board 203 has a U-shaped opening 213 , and a group of metal pads 223 are disposed beside three edges 243 of the U-shaped opening 213 . The metal pad 223 is a part of the circuit on the circuit board 203 , and the metal pad 223 is electrically coupled to the circuit (not shown) on the circuit board 203 through the metal wire 233 . A group of metal contacts 253 are disposed on the bottom surface of the circuit board 203 as the input and output contacts of the circuit on the circuit board 203 .

[0069] Such as Figure 5B As shown, the metal frame 26 has a plurality of large pieces of metal 261, and the large pieces of metal 261 are suitable for carrying high-heat-generating electronic components such as chips; a group of peripheral metal feet 262 are placed on the periphery of the metal frame 26 as a follow-up entire electronic system The output and output contacts. Subsequently, the circuit board 203 will be placed ...

Embodiment 3

[0073] Such as Figure 6A As shown, the edge of the circuit board 202 has an L-shaped opening 212 , and a set of metal pads 222 are disposed beside two edges 242 of the L-shaped opening 212 . The metal pad 222 is a part of the circuit on the circuit board 202 , and the metal pad 222 is electrically coupled to the circuit on the circuit board 202 through the metal wire 232 . A group of metal contacts 252 are disposed on the bottom surface of the circuit board 202 as the input and output contacts of the circuit on the circuit board 202 .

[0074] Such as Figure 6B As shown, the basic idea of this embodiment is the same as that of Embodiment 1-2, the only difference is that the shape of the opening of the circuit board is different. Figure 6A The display circuit board 202 has an L-shaped opening 212 , and the chip 302 is disposed on the metal surface 261S exposed by the opening 212 . The circuits in the chip 302 are electrically coupled to the circuits on the circuit board...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com