Gas discharge tube with trigger electrodes

A gas discharge tube and trigger electrode technology, which is applied to spark gaps, electrical components, and circuits with auxiliary triggering devices, can solve the problems of prolonged response time and large freewheeling current, and achieve shortened response time, stable performance, and flow through. The effect of large capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

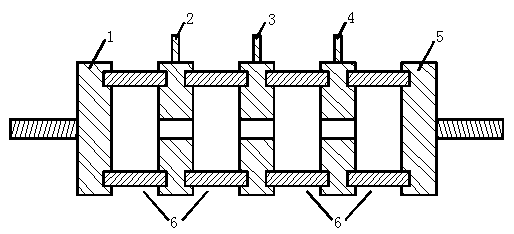

[0020] Such as figure 1 The structure schematic diagram of the present invention is shown, a gas discharge tube with trigger electrodes, including 2 main discharge electrodes 1 and 5, 3 trigger electrodes 2, 3, 4 and 4 ceramic tubes 6. The two main discharge electrodes are arranged at both ends of the gas discharge tube, and the three trigger electrodes are arranged in sequence between the two main discharge electrodes, and between adjacent electrodes (the electrodes here refer to the main discharge electrodes and the trigger electrodes) They are connected by ceramic tubes filled with inert gas argon.

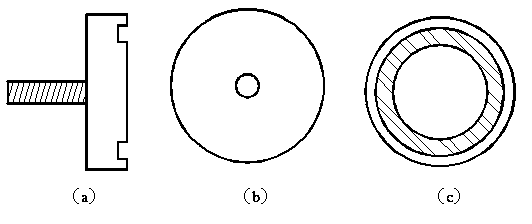

[0021] Such as figure 2 The schematic diagram of the structure of the main discharge electrode in the present invention is shown, including (a), (b), (c) 3 figures, respectively the front view, left view and right view of the main dischar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com