Photovoltaic charger control device and method

A photovoltaic charger and control device technology, applied in circuit devices, battery circuit devices, current collectors, etc., can solve problems such as maintenance, inability to guarantee battery voltage, and inability to guarantee battery voltage maintenance, so as to avoid stuck situations and track effects. Good and efficient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

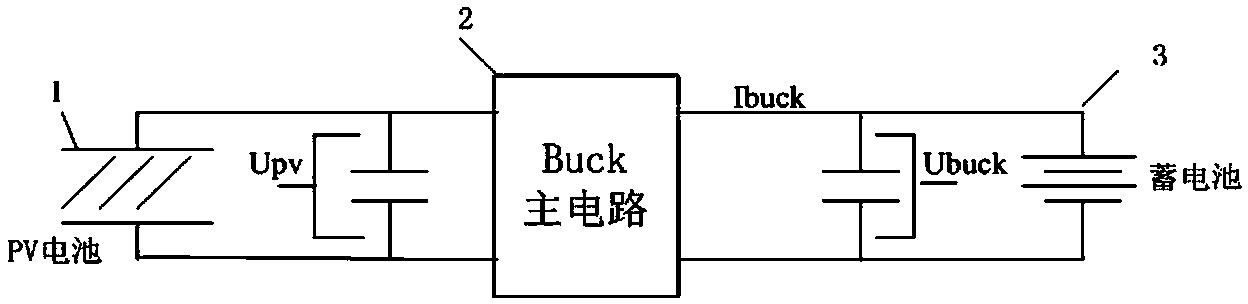

[0041] like figure 2 It is shown that the main topology of the photovoltaic charger in this embodiment is a Buck circuit.

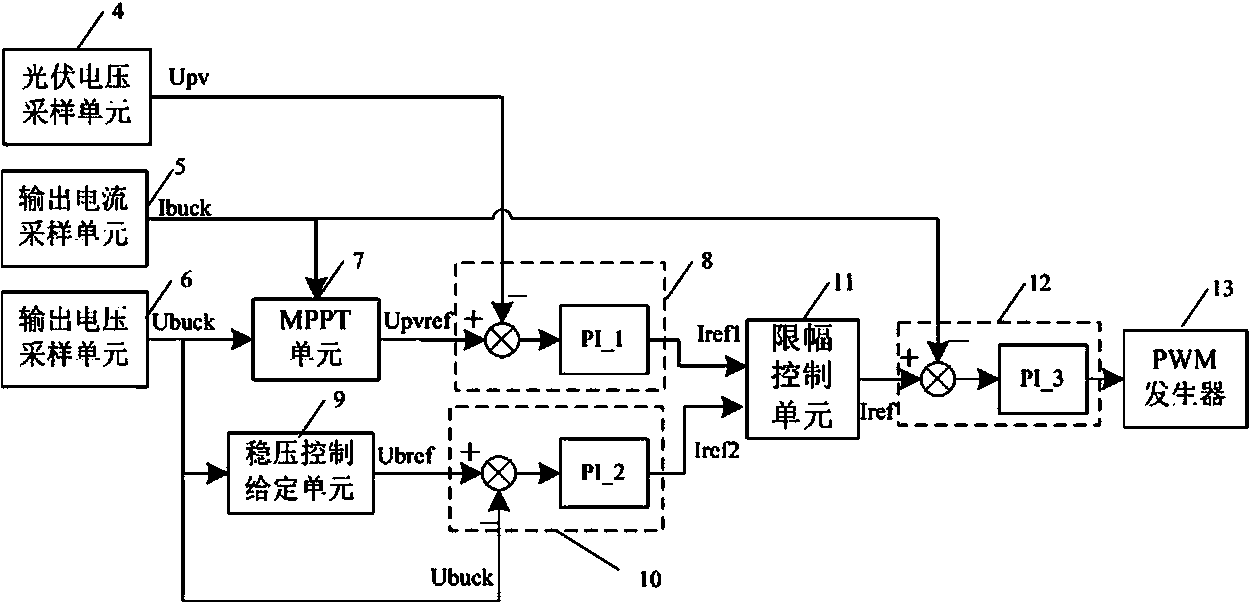

[0042] Please refer to figure 1, the present invention provides a photovoltaic charger control device, which is characterized in that it includes a photovoltaic voltage sampling unit 4 for sampling the output voltage signal Upv of the photovoltaic plate 1;

[0043] An output current sampling unit 5 for sampling the output current signal Ibuck of the photovoltaic charger;

[0044] An output voltage sampling unit 6 for sampling the output voltage signal Ubuck of the photovoltaic charger;

[0045] An MPPT unit 7, according to the output current signal Ibuck and the output voltage signal Ubuck of the photovoltaic charger,

[0046] Use the maximum power tracking technology to perform maximum power tracking on the photovoltaic po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com