Pressure-bearing type sealing cartridge used on spraying pipe inside electrothermal film

A technology of electric heating film and sealing sleeve, which is applied in ohmic resistance heating parts, fluid heaters, lighting and heating equipment, etc., can solve problems such as cable short circuit, and achieve the effect of low probability of cable short circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

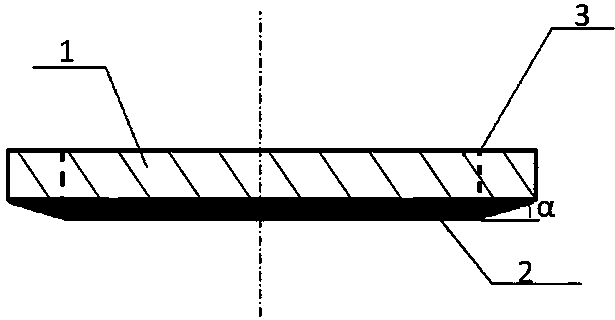

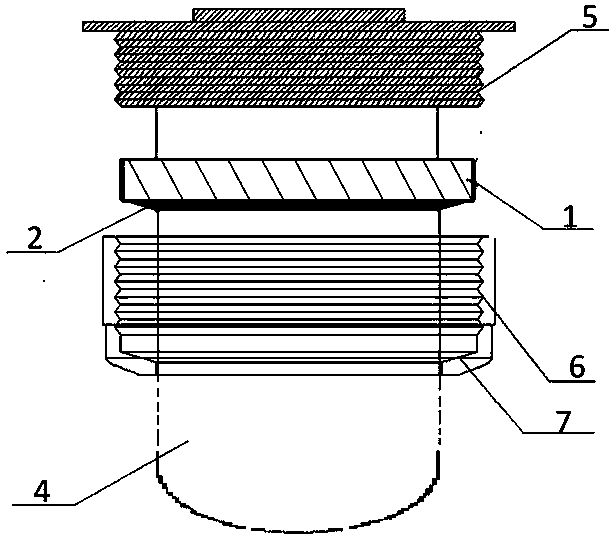

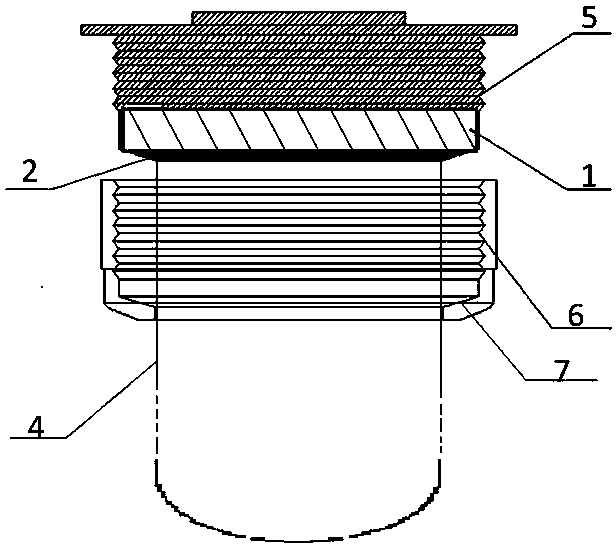

[0016] Such as figure 1 Shown is a schematic diagram of the side structure of the pressure-bearing sealing sleeve in this embodiment. The upper end of the sealing sleeve is a cylinder 1, and the lower end is a round platform 2 with an inclined side. The cylinder 1 and the round platform 2 are coaxially arranged and integrally formed. The radius of the upper bottom surface of the round platform 2 is the same as that of the cylinder 1. The radius of the lower bottom surface is smaller than the radius of the upper bottom surface, the angle α between the inclined side surface and the upper bottom surface or the lower bottom surface is greater than 0° and less than or equal to 60°, and the side of the round table 2 is designed to have a certain angle with the bottom surface. It forms a seal with the internal thread 6 on the container. In add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com