Commercial vehicles including superstructure and chassis

A technology for commercial vehicles and vehicles, applied to the upper structure, upper structure of trucks, vehicle maintenance, etc., can solve the problems of increased fuel consumption, increased air resistance, and no cleaning effect, so as to reduce fuel consumption and reduce air resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

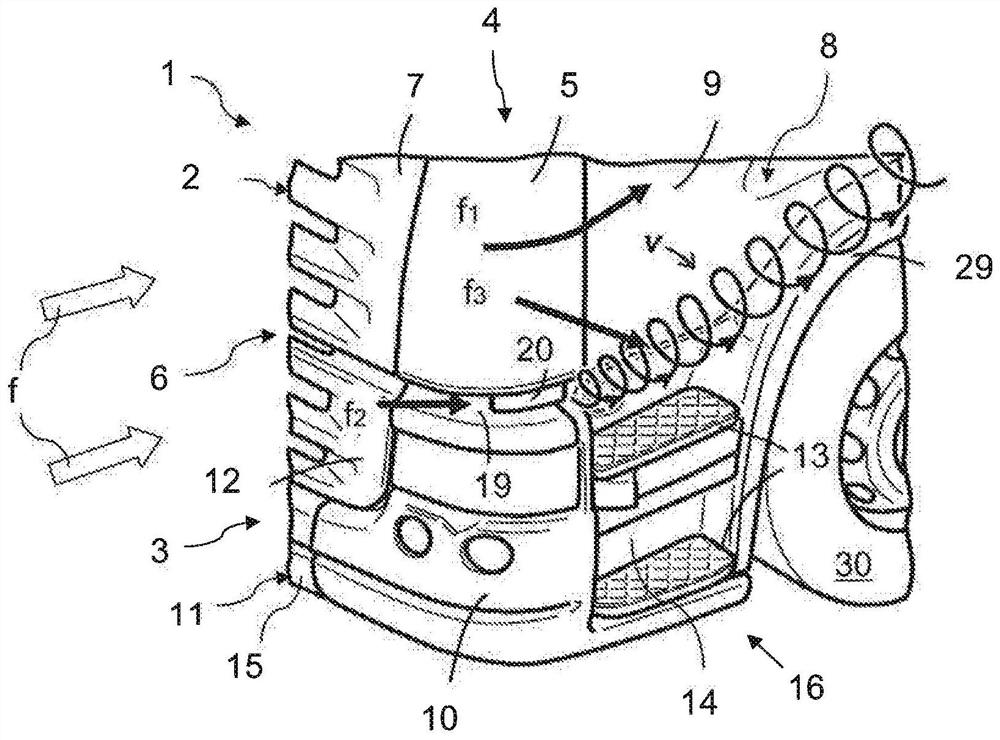

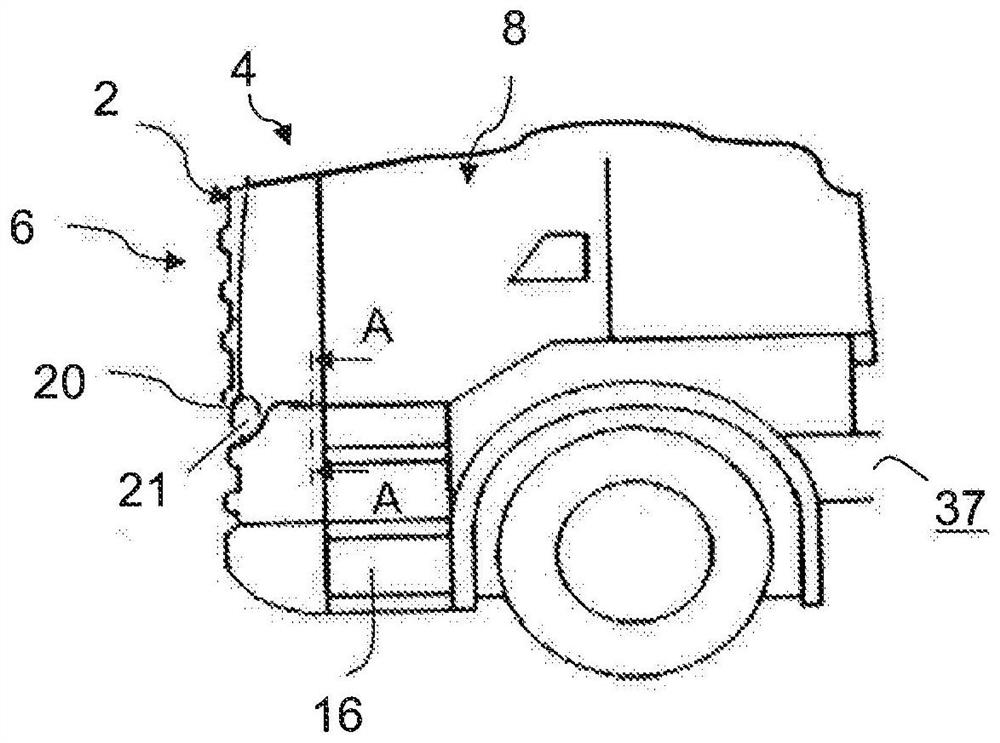

[0024] figure 1 The front of a vehicle 1 is shown, in this case a freight vehicle in the form of a tractor for towing a not shown semi-trailer. The vehicle 1 has an upper structure in the form of a cab 2, the front surface 6 of which faces forward in the direction of movement of the vehicle. The cab is elastically mounted on a frame in the form of the chassis 3 in a manner not depicted in more detail.

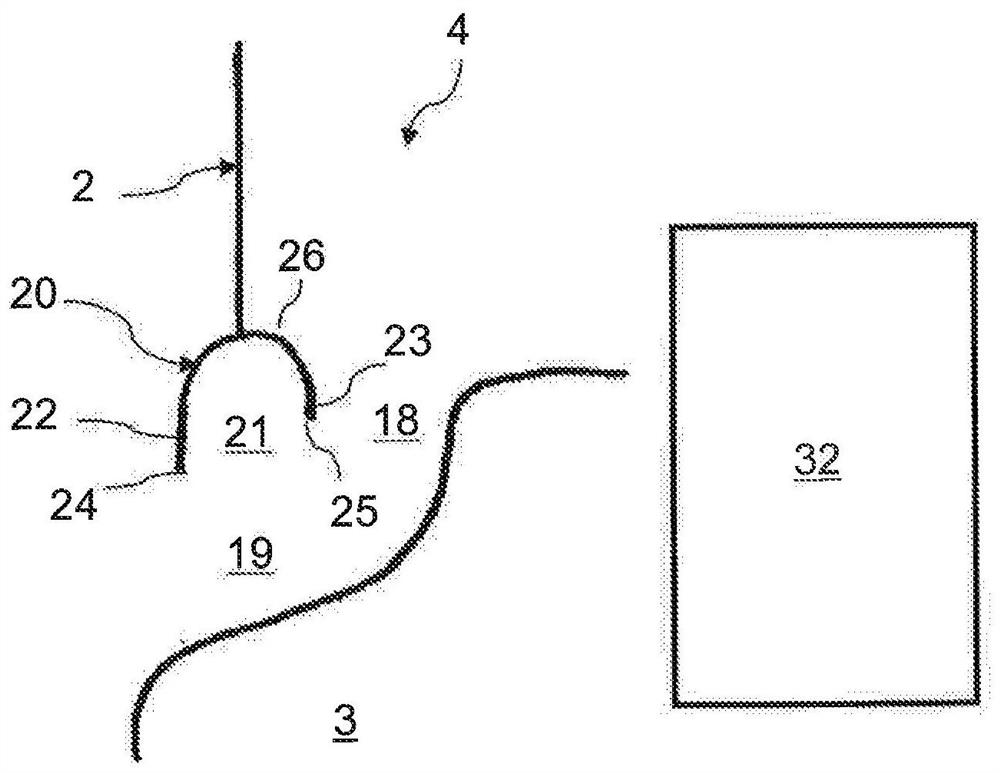

[0025] At least one front corner 4 (only on figure 1 One front corner 4) depicted in , is located on each side of the front surface 6. At the level of the cab 2, each corner 4 takes the form of a curved corner panel 5 situated between an upper front hatch 7 forming part of the front face 6 and a side 8 which Extends rearwardly from the corner in the direction of motion of the vehicle and includes the door 9 . At the level of the chassis 3 , the corner 4 takes the form of a curved portion 10 of a bumper 11 . The upper portion of the curved portion 10 extends between a lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com