Structured aqueous liquid detergent

An aqueous liquid, structured technology, applied in detergent materials, detergent compounding agents, detergent compositions, etc., can solve the problems of using or not using together, increasing the complexity of preparations, and achieving the effect of flexible processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

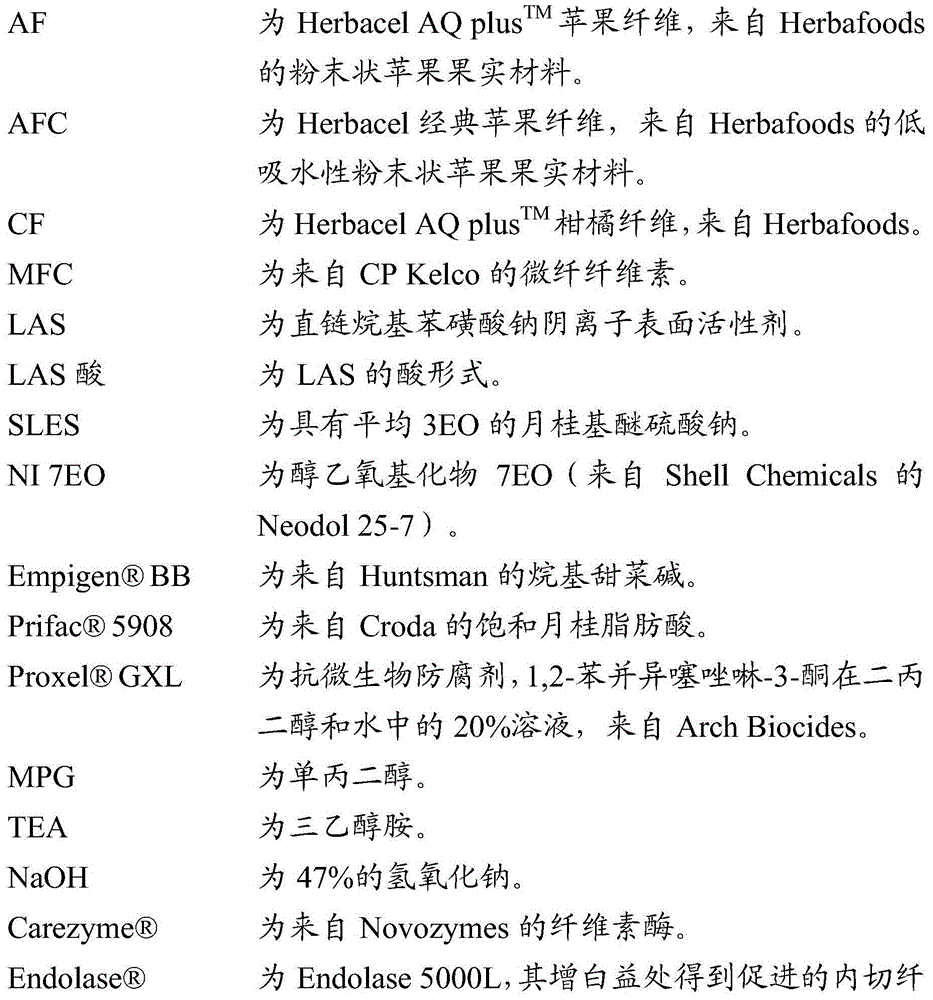

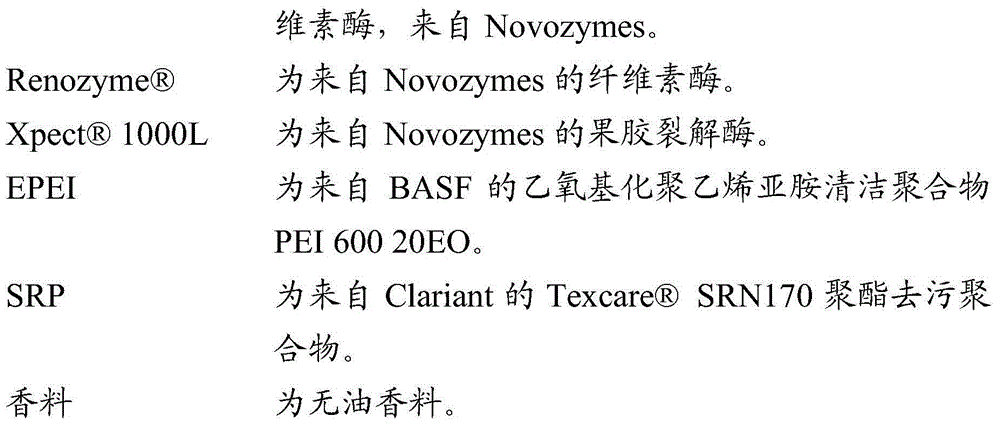

[0128] The invention will now be further described with reference to the following non-limiting examples. These abbreviations are used in the examples:

[0129]

[0130]

[0131] Example 1 and Comparative Examples A and B - Premixes

[0132] Three premixes were prepared using high intensity high shear mixing. All premixes were sheared and dispersed with a Silverson mixer. The added preservatives are

[0133] AFC (classic apple fiber) has a low water-binding capacity of less than 10 kg / kg, while both AF (apple AQ+) and CF (citrus AQ+) have water-binding capacities above this value and their capacities are shown in premixes The high shear applied during the preparation is further increased.

[0134] Table 1 - Premix Composition

[0135] Weight % as supplied

[0136] Classic apple fiber did not produce a stable premix and therefore could not be used for structuring. Each of the other structurants provided a satisfactory homogeneous premix suitable for us...

Embodiment 2 and comparative example D

[0137] Embodiment 2 and comparative examples D and E

[0138] The premixes from Example 1 and Comparative Examples A and B were dispersed into a concentrated aqueous laundry detergent liquid base to form the structured liquids shown in Table 2.

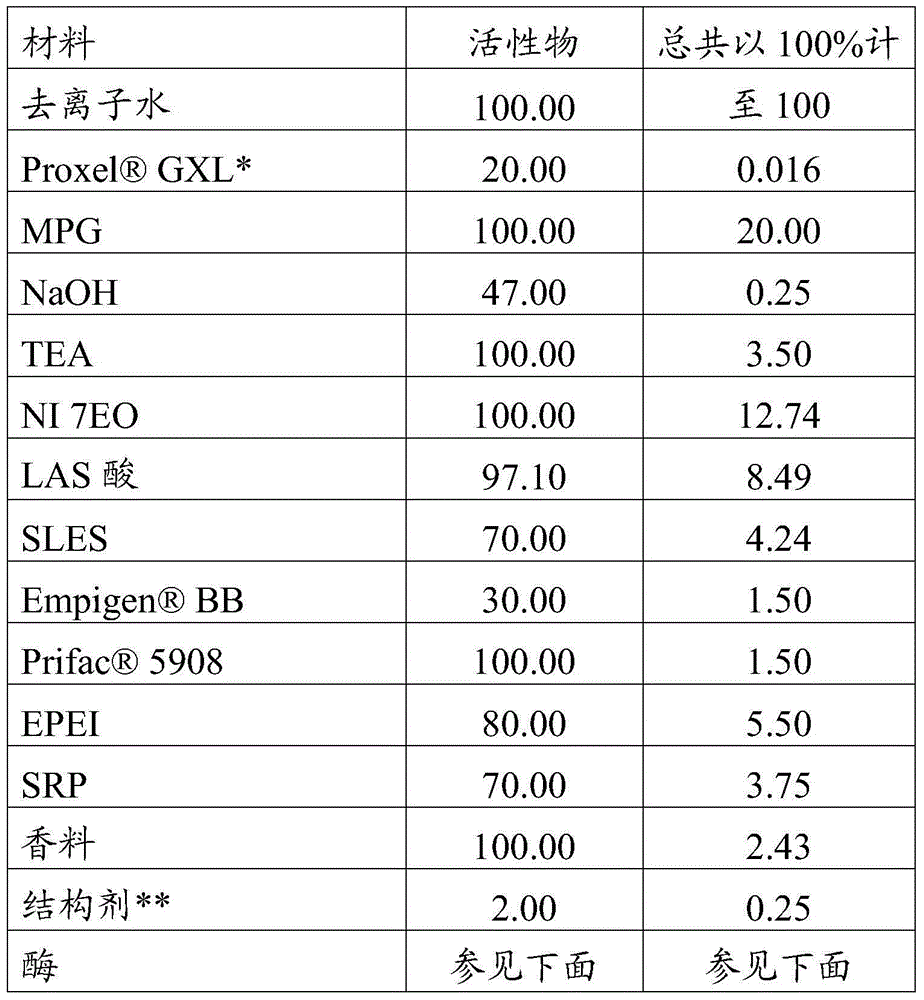

[0139] Table 2 - Composition of detergent liquid bases

[0140]

[0141] *Proxel was added to both the base and the activated apple fiber premix. It was present in both at a level of 0.08% by weight, calculated as is. Since it is a 20% by weight solution, the 100% active level is 0.016% by weight.

[0142] **Premix prepared in Example 1 or D.

[0143] The concentrated base detergent mix in Table 1 was circulated through the circulation loop through a 150 / 250 Silverson L4R high shear mill to ensure all lines were fully primed and purged of air. The flow rate was 1450 L / hour (with a residence time in the mill of 0.1 seconds per pass). The Silverson mill was started at 6250 rpm (9063 w / kg) to simulate large scale operating cond...

Embodiment 3

[0146] Example 3 - Enzyme addition and long-term effect on rheology

[0147] Cellulases are known to be effective in removing cotton balls. Pectin lyase will attack the pectin in the apple pulp mixture.

[0148] Eight new samples were made based on Example 2 and Example D, but a portion of the water was replaced by the following four types and amounts of enzymes dispersed into the modified liquid with sticks. For Examples 2 and D, the treatment was continued until the enzyme was added. The level of incorporation of each enzyme was chosen to be a level suitable for effective performance when provided from a 20ml concentrated laundry detergent base.

[0149] 0.5% by weight Endolase 5000L (cellulase)

[0150] 0.5% Renozyme (cellulase) by weight

[0151]2.4% by weight of Xpect 1000L (pectin lyase)

[0152] 0.5% Carezyme (cellulase) by weight

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com