Seal assembly for rotary piston internal combustion engine

A technology for rotating pistons and internal combustion engines, which is applied to the sealing device of engines, internal combustion piston engines, reciprocating piston engines, etc., and can solve the problems of increasing wear, reducing the tightness and durability of seals, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

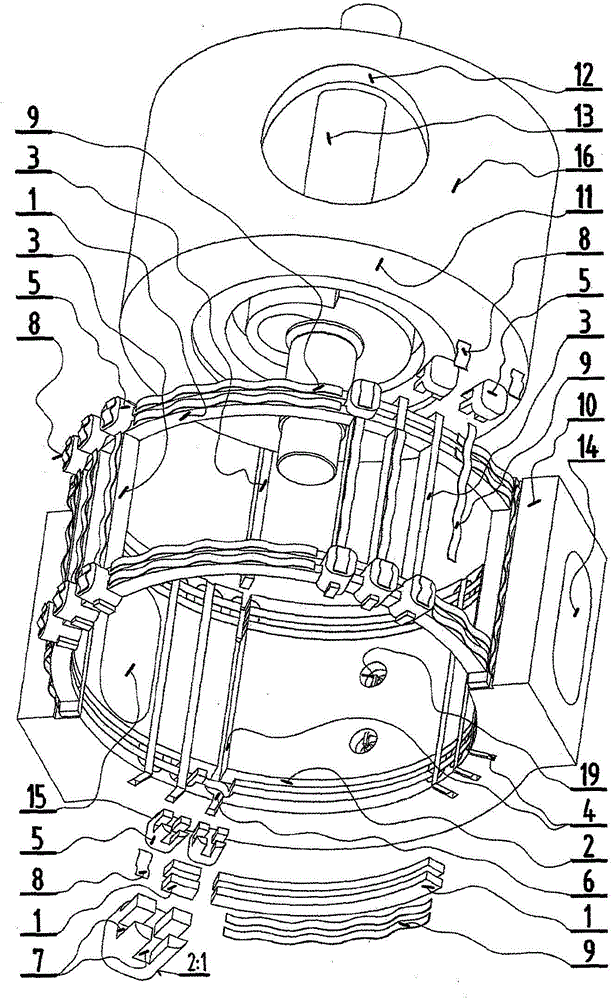

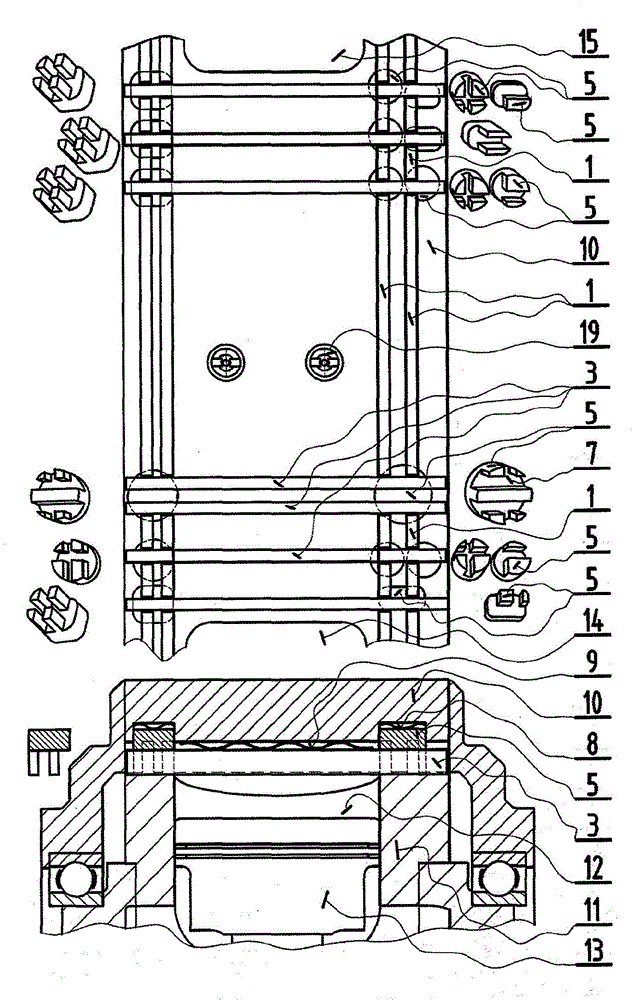

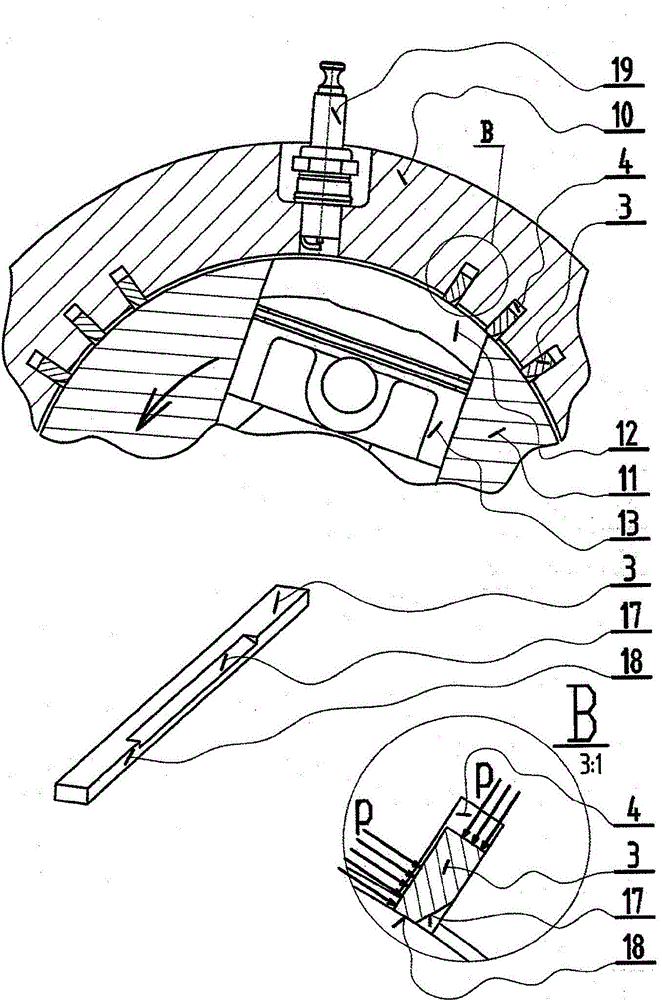

[0019] Such as figure 1 As shown, the embodiment of the sealing assembly of the rotary piston internal combustion engine provided by the present invention includes a circular side sealing section 1 , a transverse sealing strip 3 , a joint 5 , elastic pieces 8 and other elastic pieces 9 . All the above-mentioned components are arranged in a fixed housing 10, which also has a rotating block 11, the rotating block 11 is radially provided with a cylinder 12 and a piston 13, and its outer surface 16 is a rotatable cylindrical surface. The fixed housing 10 has an air inlet 14 and an air outlet 15 , and the side sealing sections 1 are disposed in the circular side groove 2 and arranged in two rows. Each elastic piece 8 and joint 5 are located in the opening 6 , the horizontal seal 3 is set in the horizontal groove 4 , and the other elastic pieces 9 are set in the horizontal groove 4 and the side groove 2 . There are three horizontal seals 3 between the spark plug 19 and the air inl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com