Sweet potato peeling washing and airing integrated structure

A sweet potato and integrated technology, which is applied in the peeling of vegetables or fruits, food processing, food science, etc. It can solve the problems of affecting the quality of vermicelli, uneven water spraying, and excessive moisture on the surface of sweet potatoes, etc., and achieves simple and convenient operation and convenient use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

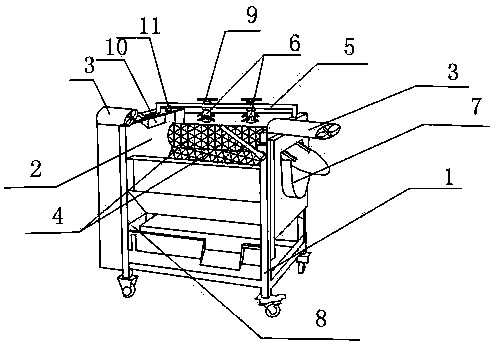

[0019] Such as figure 1 Shown, the present invention comprises frame 1, blower fan 3, cleaning chamber 2 installed on frame 1 and a plurality of cylinders 4 installed in cleaning chamber 2, a large amount of wool is evenly arranged on the outer surface of each cylinder 4 Brush, the discharge port 7 is set on the side wall of the cleaning chamber 2, the slag discharge channel 8 is set at the bottom of the cleaning chamber 2, and the water pipe 5 is spanned at the top of the cleaning chamber 2, and the two ends of the water pipe 5 are fixed on the frame 1 On the top of the water pipe 5, a plurality of rotating nozzles 6 are arranged, and the rotating nozzles 6 are all facing in the cleaning chamber 2, and the top of the cleaning chamber 2 is open; a motor is also installed on the frame 1, and the motor is connected with a plurality of cylinders 4; A plurality of blowers 3 are also arranged on the top of the frame 1 , and each blower 3 is aimed at the cleaning chamber 2 , and a h...

Embodiment 2

[0022] The preferred specific structure of this embodiment on the basis of embodiment 1 is as follows: an alarm 11 is installed above the inner wall of the cleaning chamber 2 . When the sweet potatoes in the cleaning chamber are air-dried to meet the standard, the alarm will sound to remind the operator to turn off the fan in time.

[0023] A switch 9 is arranged on each rotary nozzle 6 . It is convenient to individually control the working or closing of a single rotary nozzle, as well as the size of the water spray.

[0024] The rotating nozzle 6 is provided with a plurality of water outlets. Further increase the area of sweet potatoes in the cleaning chamber sprayed by a single nozzle, so that all areas in the cleaning chamber can be sprayed with water, and the washing of sweet potatoes is more in place, cleaner and faster.

[0025] The discharge port 7 is adjacent to one end of the drum 4, and a cover body opened and closed by a rotating rod is arranged on the discharge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com