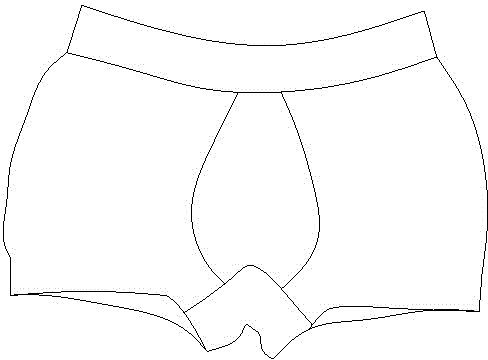

Shaping and producing process of men's underwear

A molding process and manufacturing process technology, applied to sewing tools, underwear, clothing, etc., can solve problems such as wearing discomfort, and achieve the effect of strong overall structure and comfortable wearing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Step 1: The designer draws the shape of the underwear size L.

[0044] The second step: the designer performs programming, combining the drawing drawn in the first step with the program, and such a program is directly input into the machine for execution.

[0045] The third step: on the machine, first of all, put all kinds of raw materials you need into the machine. Then import the previously compiled program into the machine (the machine we use is the Santoni SM8 TOP2 seamless underwear machine imported from Italy), weave the product, and record the weight, waist width, and time of the fabric when it is off the machine. None of the three.

[0046] The fourth step: Dyeing. If the size after dyeing meets the requirements, then it is ok. If it does not meet the requirements, it must be modified.

[0047] Step 5: Enter the back sewing workshop and remove unnecessary things. The next step is to carry out ironing and shaping. Finally, set the label we specified.

[0048...

Embodiment 2

[0050] Step 1: The designer finds the L size drawing we made before in the Graph6 photon drawing software, scales it up, and makes it XL size.

[0051] The second step: also use Graph6 quasar programming software to enlarge the model, and change the number of revolutions of the machine if necessary.

[0052] Step 3: Get on the machine. At this time, the machine is the same as the above steps, but there is a difference. If there is an L size, we can release the weight, waist width, and time of the XL size. Weave white embryos directly on the machine.

[0053] The fourth step: Dyeing. If the size after dyeing meets the requirements, then it is ok. If it does not meet the requirements, it must be modified.

[0054] Step 5: Entering the back sewing workshop, first cut off the excess cloth, then stitch the crotch with four needles and six threads, and then trim and remove unnecessary things from the thread ends. The next step is to carry out ironing and shaping. Finally, set the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com