Die forging crankshaft and connecting rod trimming die device

A technology for trimming dies and crankshafts, which is used in forging/pressing/hammer devices, manufacturing tools, forging/pressing/hammering machines, etc. It can solve the problem of affecting the installation position and adjustment of the upper punch and lower die, and it is inconvenient to adjust. The position of the upper punch and the large space occupied by the discharge top plate can achieve the effect of simple structure, convenient maintenance and small occupied space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

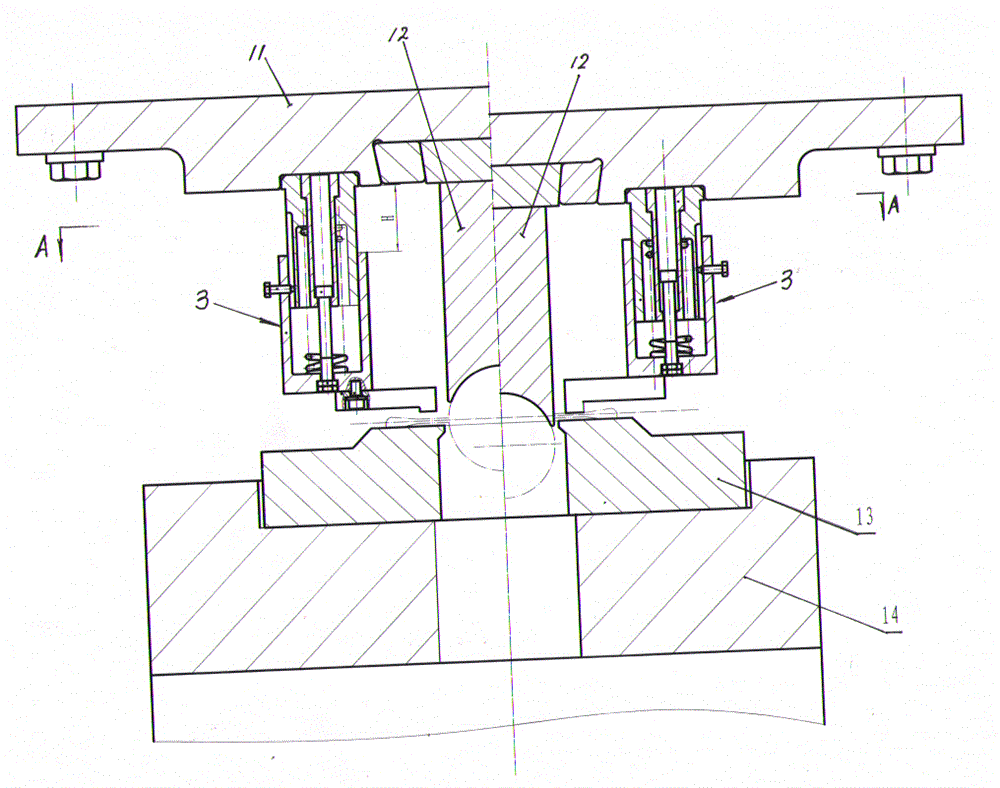

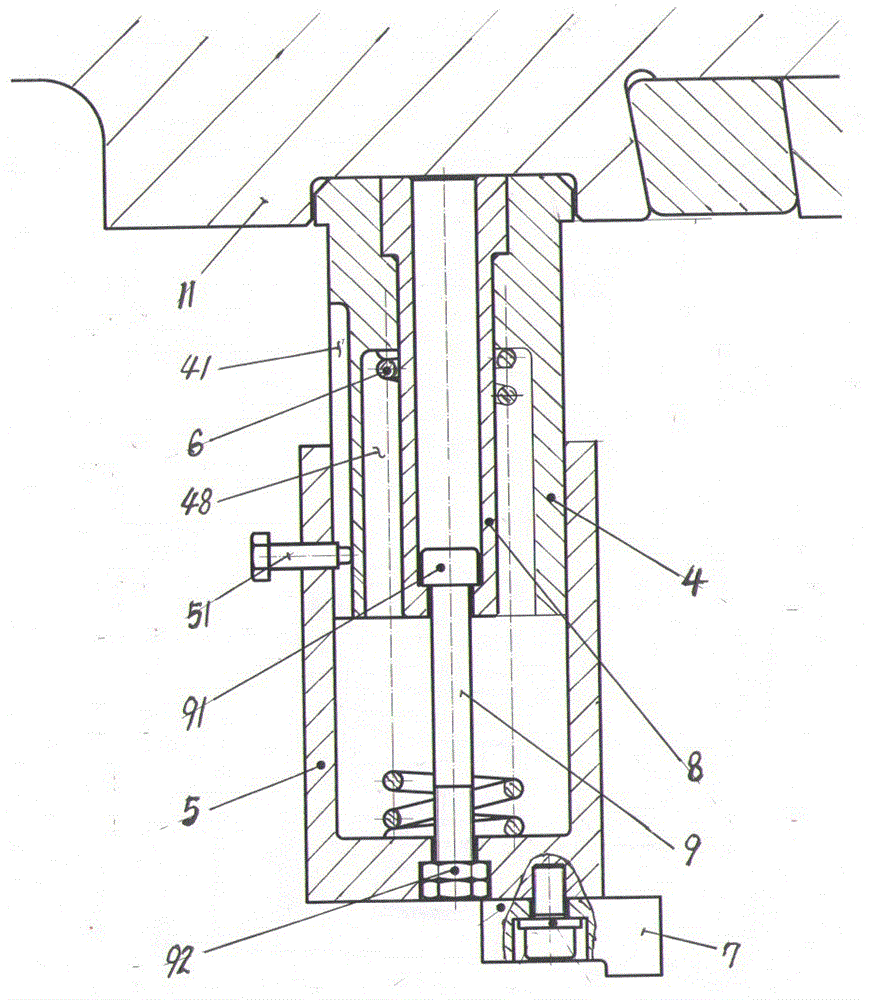

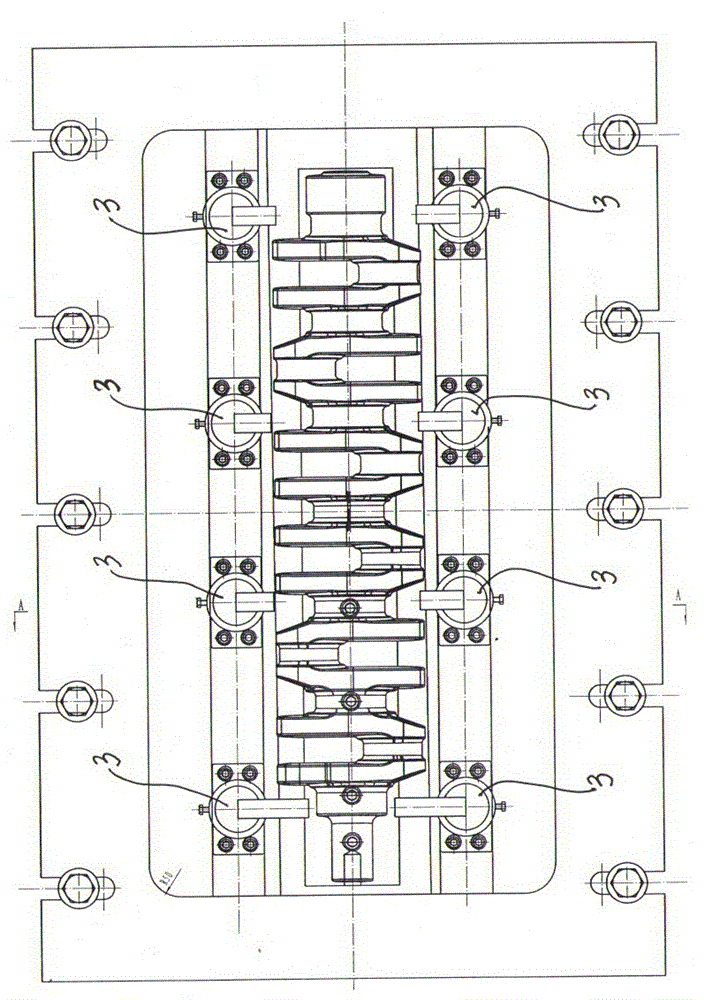

[0018] The edge trimming mold device of the present invention comprises an upper template 11, an upper punch 12, a lower die 13, a backing plate 14 under the die, and a device for unloading flash. The upper punch 12 is fixedly installed on the upper template 11, and the lower die 13 is installed on the backing plate 14 of the die, and is characterized in that a plurality of flash unloading devices 3 are distributed on the upper template 11, and the flash unloading device 3 consists of an inner sleeve 4, an outer sleeve 5, a spring 6, and a top material block 7 Composition, the upper end of the inner sleeve 4 is fixedly installed with the upper template 11, the outer sleeve 5 and the inner sleeve 4 slide and cooperate in a limited position, an anti-rotation mechanism is provided on the sliding mating surface of the outer sleeve 5 and the inner sleeve 4, and the spring 6 is installed in the inner sleeve 4 and the pressure acts on the jacket 5, and the lower end surface of the jac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com