Special-shaped pipe sawing method

A special-shaped pipe and sawing technology, applied in the field of pipe processing, can solve the problems of difficult shaping, deviation, and poor sawing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

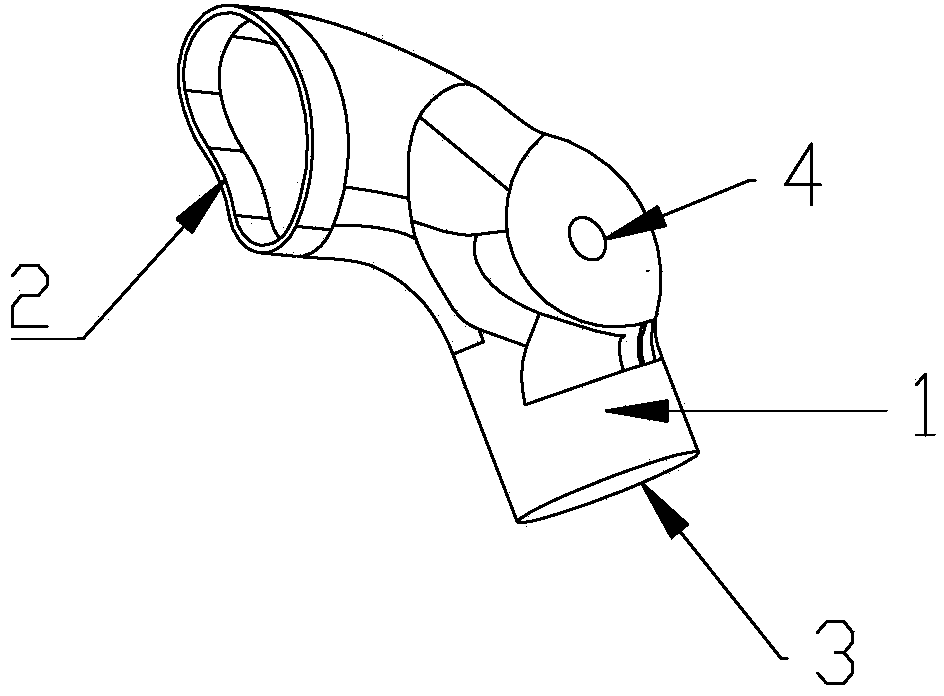

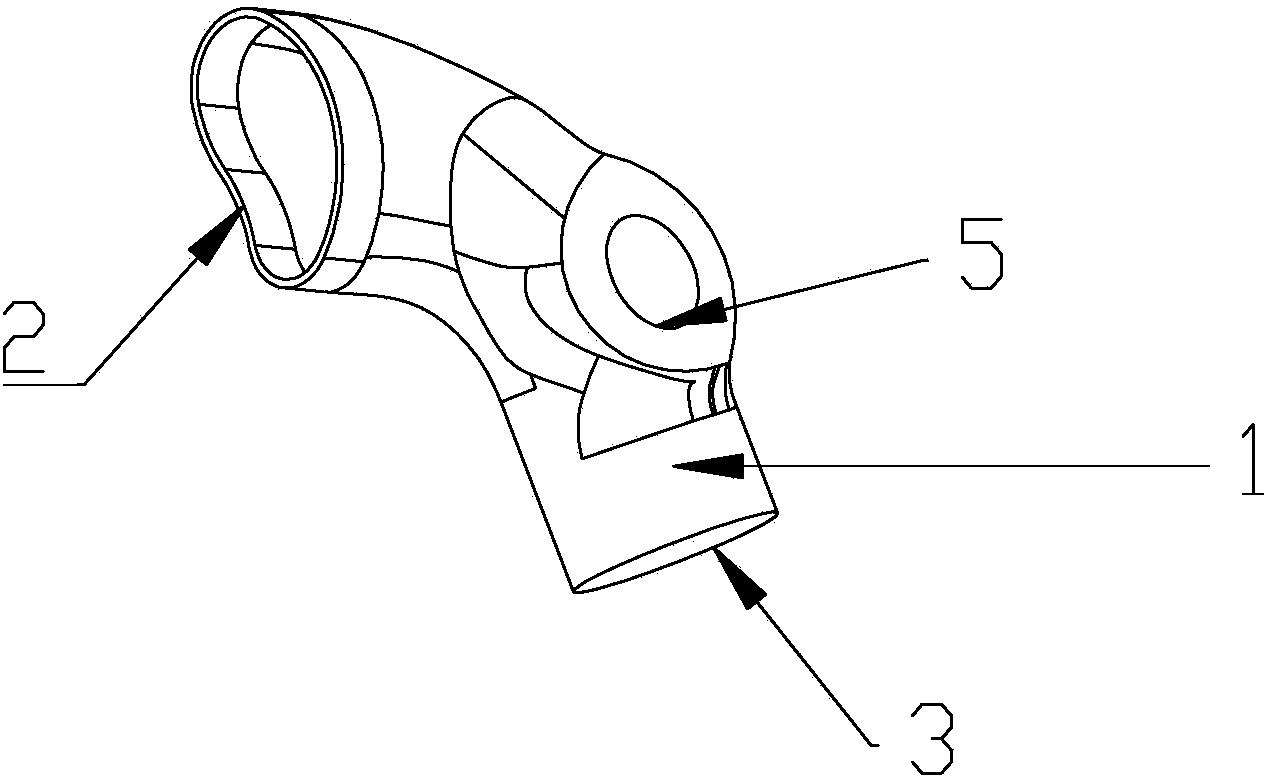

[0018] Such as figure 1 figure 2 As shown, the invention provides a special-shaped pipe sawing method, which comprises the following steps:

[0019] a. Mill a process hole 4 at the pre-punched position of the special-shaped pipe in the pipe fitting to be sawed;

[0020] b. Put part of the pipe fittings that are special-shaped pipes into the clamp and clamp them, and saw the special-shaped pipe fittings from the pipe fittings;

[0021] c. Put the special-shaped pipe sawn in the previous step into the first special-shaped pipe fixture. The first special-shaped pipe fixture is provided with a first through hole corresponding to the position of the process hole on the special-shaped pipe, and the bolt passes through the process. The hole and the first through hole secure the special-shaped pipe in the first special-shaped pipe fixture, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com