Drill-rivet method for semi-closed cage type thin-wall inter-box housing section

A semi-closed, birdcage technology, applied in the field of drilling and riveting, can solve the problems of incomplete application and poor opening, and achieve the effects of low riveting noise, improved drilling and riveting efficiency, and high one-time pass rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0024] A method for drilling and riveting shell segments between semi-enclosed birdcage-type thin-walled boxes, comprising the following steps:

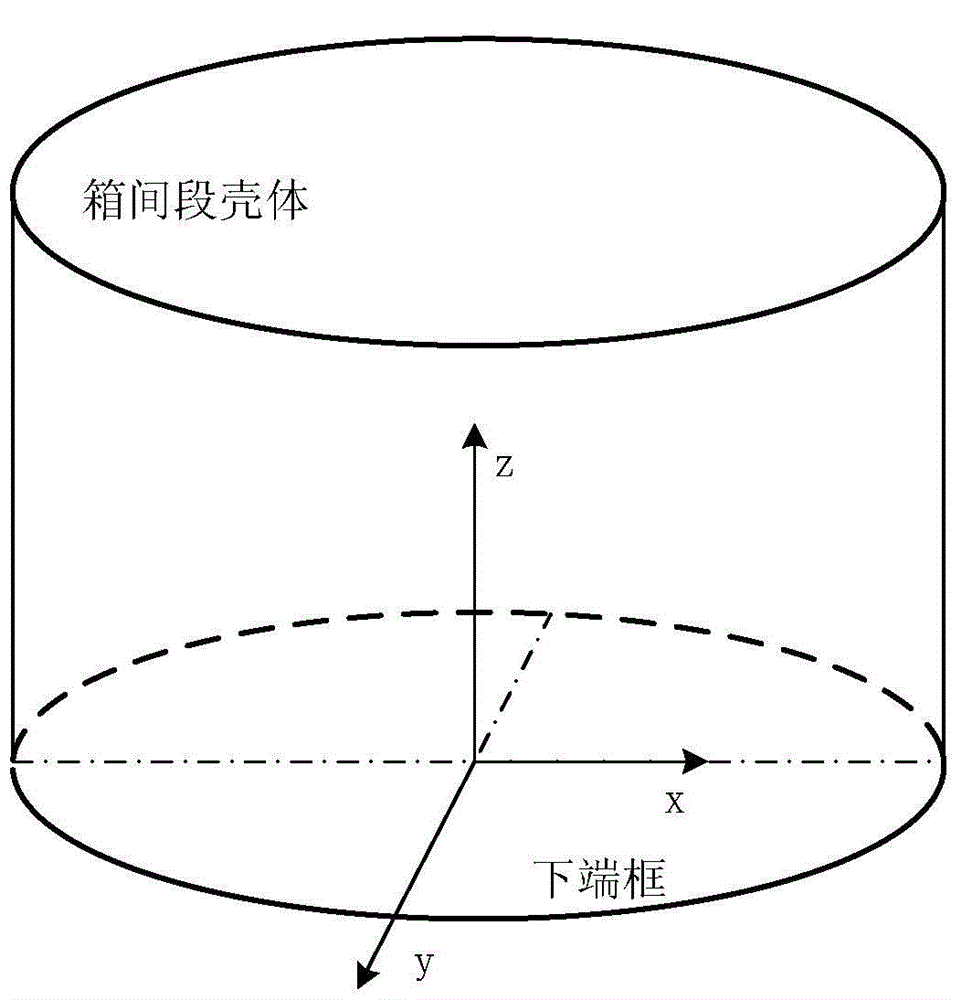

[0025] Step 1: Take the center of the circle on the butt joint surface of the lower end frame of the inter-box section as the origin, establish the spatial x, y, z coordinate system of the inter-box section; and establish the rivet hole position coordinates in this coordinate system. Such as figure 1 shown;

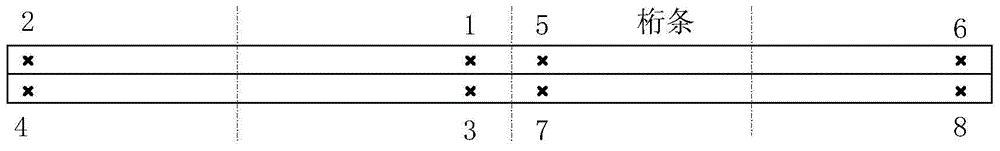

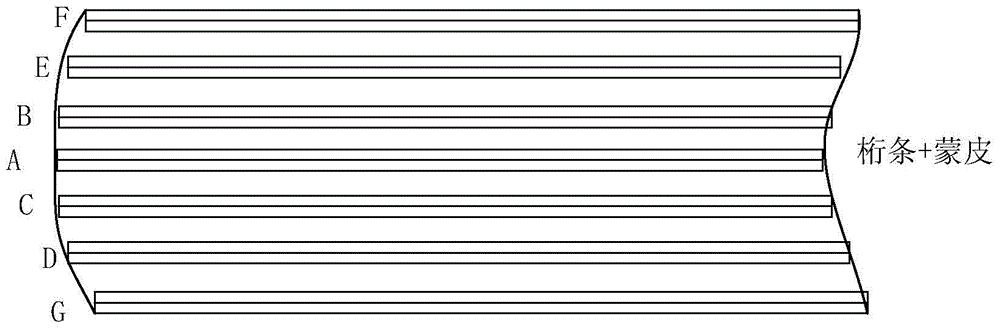

[0026] Step 2: According to the rivet point data, plan the drilling and riveting program walking paths of the front and rear end frames, middle frames, and stringers according to the riveting sequence; for a single stringer, in order to ensure the release of riveting stress, the riveting path for hole making is along the stringer direction, the order is: 1-2, 3-4, 5-6, 7-8 such as f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com