A kind of monolithic chromium oxide catalyst for alkali treatment and its preparation method and application

A monolithic catalyst and chromium oxide technology, which is applied in the direction of catalyst activation/preparation, physical/chemical process catalyst, metal/metal oxide/metal hydroxide catalyst, etc., which can solve the problem of low catalytic efficiency of catalyst and embedding of active components , Low specific surface area and other issues, to achieve the effect of improving NO storage performance, improving stability, and increasing specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Preparation of monolithic catalysts with chromium oxide coating by impregnation method:

[0022] Weigh 100.0g of chromium nitrate and dissolve it in 200ml of deionized water, stir at room temperature, dissolve evenly, pour it on the cordierite honeycomb ceramic carrier, after repeated dipping, dry at 100°C, and bake at 300°C for 4 hours to obtain a chromium oxide coating monolithic catalyst.

[0023] Alkali treatment method prepares monolithic chromium oxide catalyst:

[0024] In the way of excessive impregnation, soak the monolithic catalyst with chromium oxide coating prepared above in lye, ammonia water, pH=8-10, after soaking for 2 hours, put it in 100 o After drying in an oven for 12 h, the catalyst was calcined at 300 °C for 4 h in a muffle furnace to obtain the catalyst.

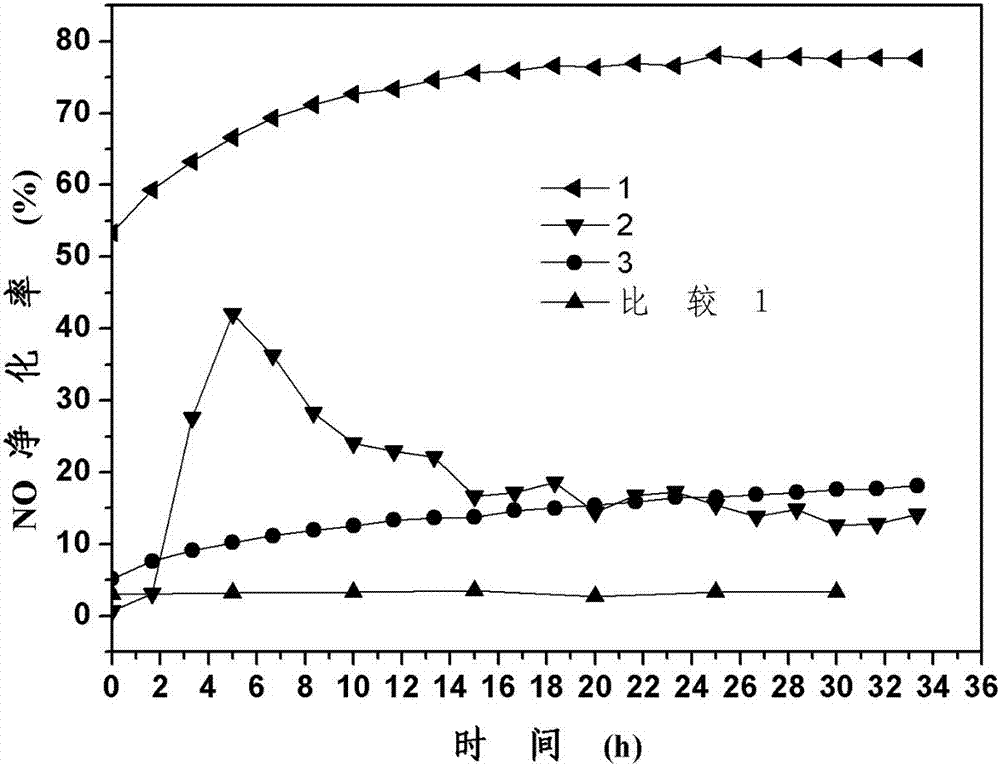

[0025] Put the above-prepared 10*10*10cm monolithic catalyst in the reactor, pass the reaction gas at room temperature, and conduct the activity test. The gas composition is 15 ppm NO, the re...

Embodiment 2

[0027] Compared with Example 1, the difference is that the lye is an ammonium bicarbonate solution, and the amount of other materials and operating conditions are the same as in Example 1.

Embodiment 3

[0029] Compared with Example 1, the difference is that the lye is a KOH mixed solution, and the amount of other materials and operating conditions are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com