A Conical Nut Pushing Pretensioning System

A conical nut, jacking technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., to achieve the effect of firm and reliable pre-tightening, reducing thread stress, and reducing friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

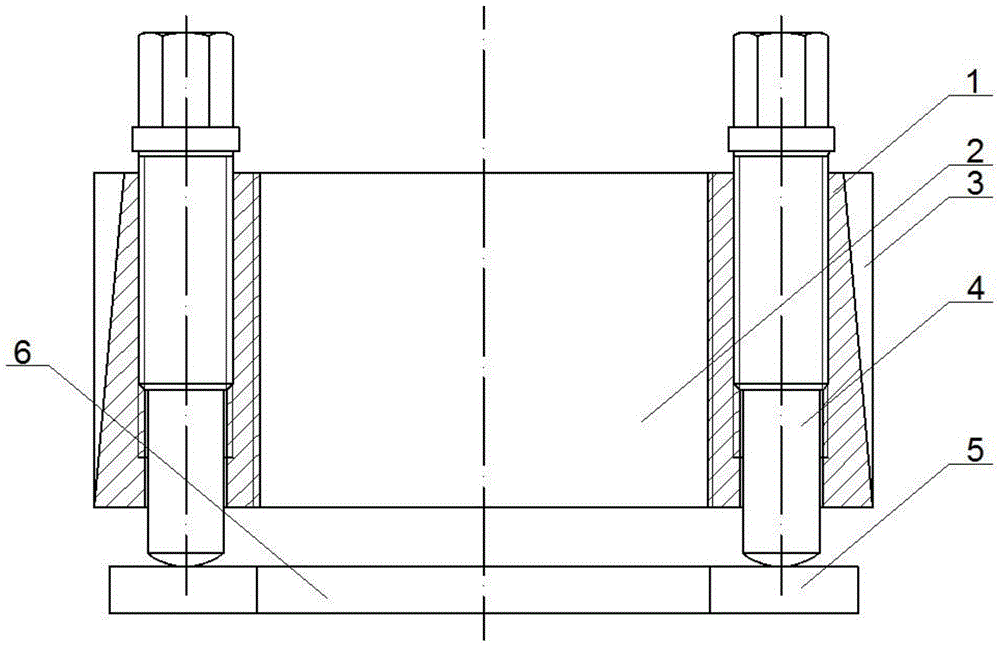

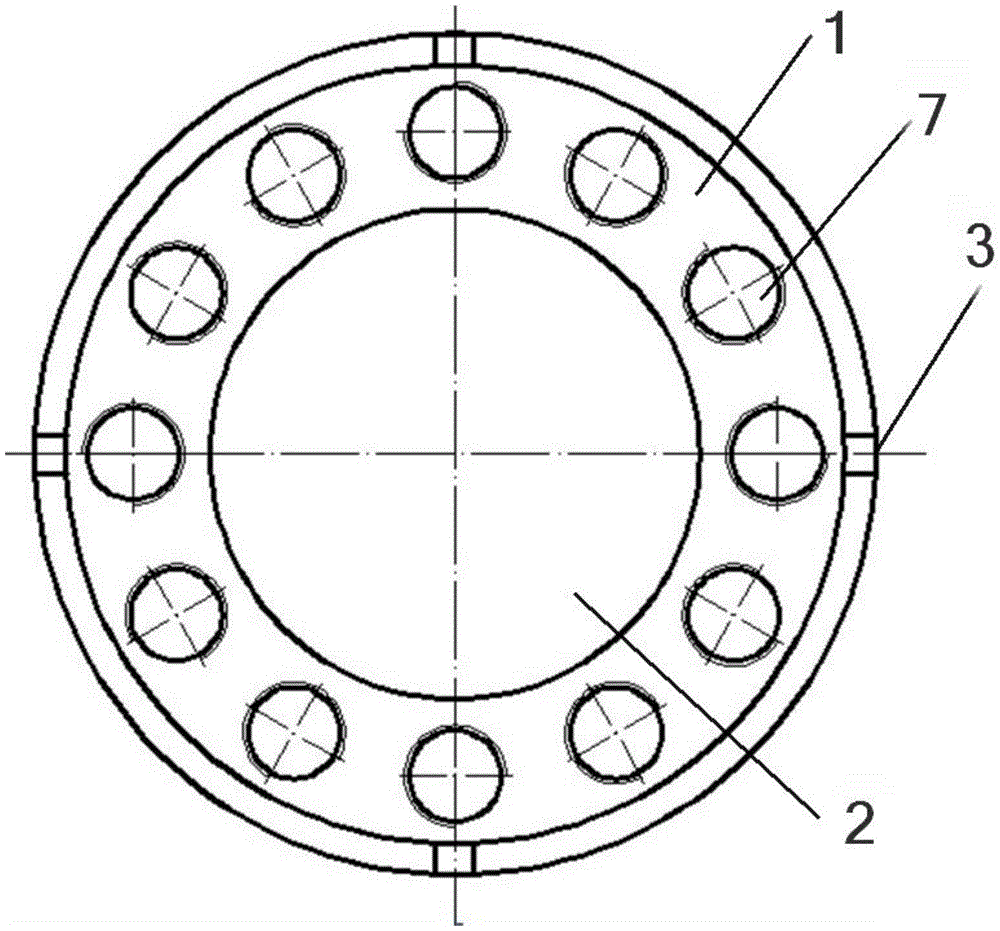

[0026] Such as figure 1 , figure 2 , a tapered nut jacking preloading system, the tapered nut jacking preloading system includes a tapered nut body 1, circumferentially evenly distributed small jacking bolts 4 and superhard gaskets 5, the tapered nut body 1 has an outer conical surface with a half-cone angle of θ. In the embodiment, θ is 3 degrees. There are several fins 3 on the outer conical surface. The central hole 2 cooperates with the bolt shank of the fastener. A number of small bolt holes 7 are evenly distributed around the cylindrical threaded central hole 2 in a circular shape, and the number of the small bolt holes 7 varies with the diameter of the tapered nut ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com