Plastic rod handling device

A technology of handling device and plastic rod, applied in metal processing and other directions, can solve the problems of labor consumption, low handling efficiency, heavy weight, etc., and achieve the effects of simple structure, manpower saving, and improved handling efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

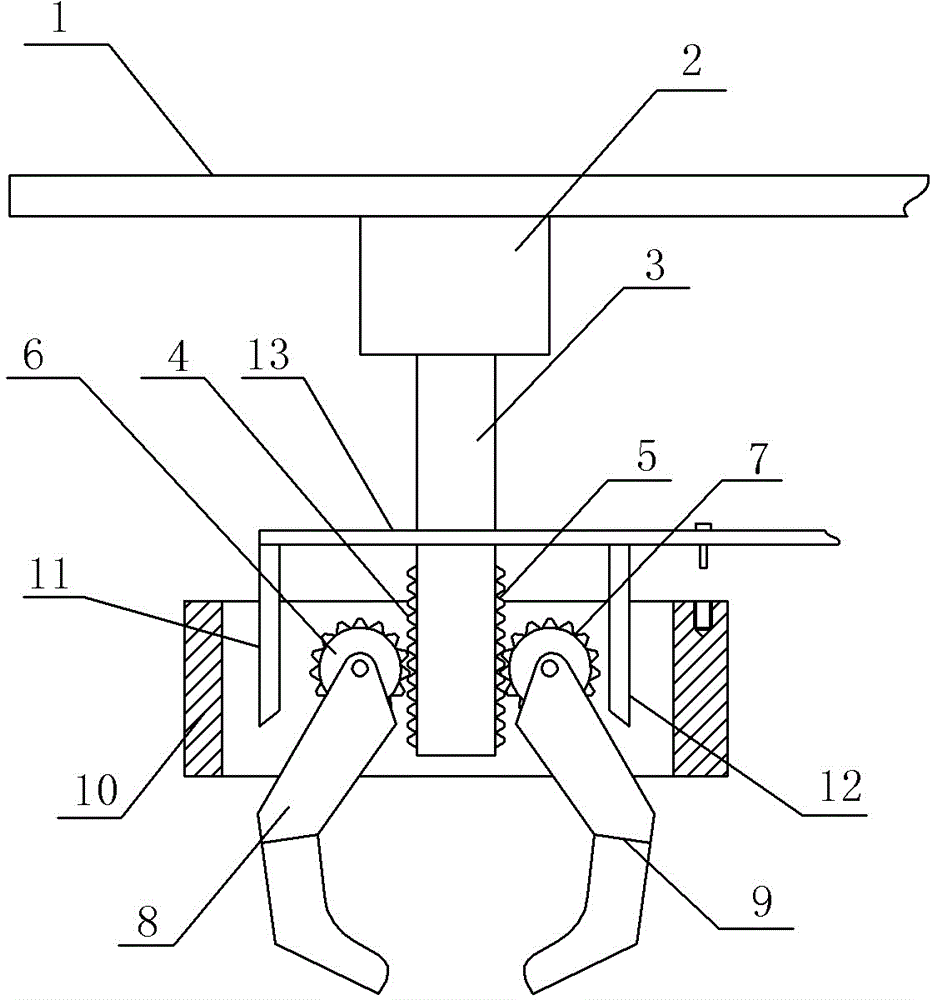

[0013] Embodiment 1: attached figure 1 The reference signs in include: 1-guide rail, 2-cylinder, 3-cylinder rod, 4-left rack, 5-right rack, 6-left gear, 7-right gear, 8-left gripper, 9- Right grip claw, 10-installation platform, 11-left locking lever, 12-right locking lever, 13-driving lever.

[0014] as attached figure 1 As shown, the plastic rod handling device includes a handling trolley, a horizontal hanger is installed above the handling trolley, and a mounting platform 10 is fitted on the handling trolley below the hanger through bolts, and a horizontal guide rail 1 is arranged on the hanger. The sliding fit has a slider, and the movement of the slider is controlled by an oil cylinder.

[0015] A vertically downward cylinder 2 is fixed on the slider, and the cylinder rod 3 is inserted into the cavity in the middle of the mounting table 10. The two sides of the cylinder rod 3 are respectively welded with a vertical left rack 4 and a right rack 5. A left gear shaft is f...

Embodiment 2

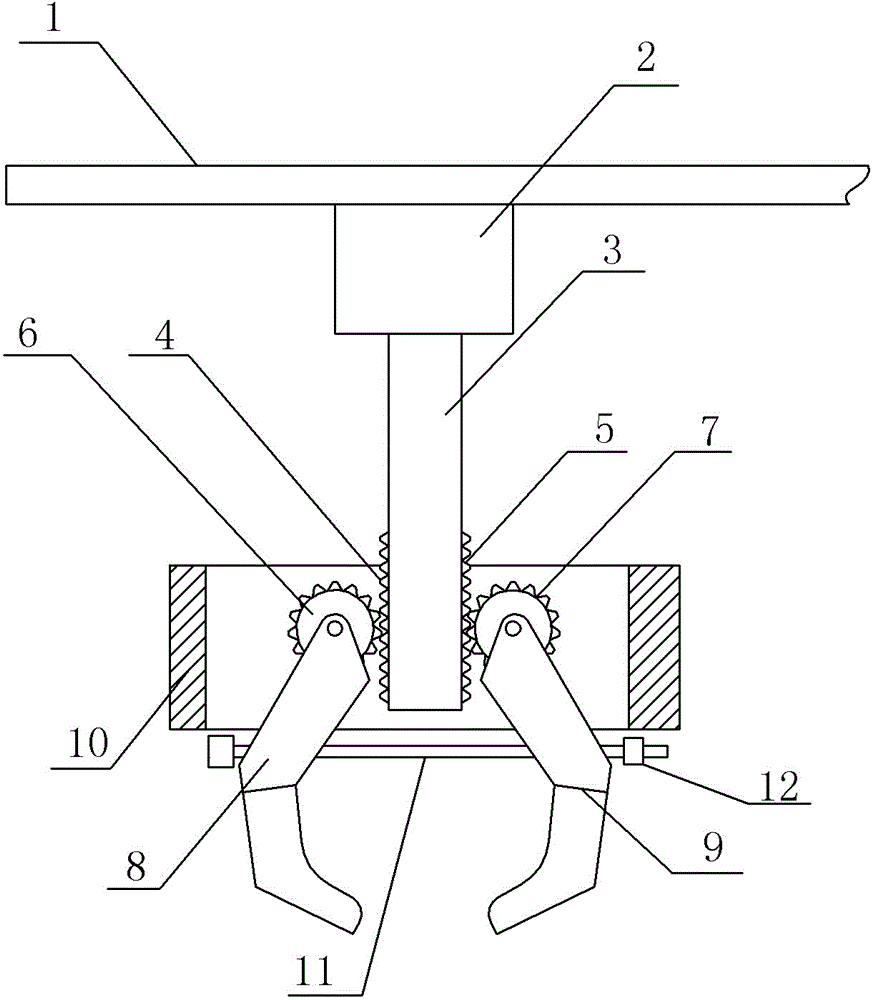

[0017] Embodiment 2: attached figure 2 The reference signs in include: 1-rail 1, 2-cylinder 2, 3-cylinder rod, 4-left rack, 5-right rack, 6-left gear, 7-right gear, 8-left gripper, 9-right claw, 10-installation platform, 11-screw rod, 12-nut.

[0018] The difference between embodiment 2 and embodiment 1 lies in that a screw rod 11 runs through the left gripper 8 and the right gripper 9 transversely, and a locking nut 12 is provided on the bolt. When the gripper clamps the plastic rod, the screw rod 11 is withdrawn. After the clamping is completed, the screw rod 11 can be passed through the screw holes of the left gripper 8 and the right gripper 9, and locking can be realized after tightening the locking nut 12.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com