Biomass particle and rodlike fuel forming machine

A technology of biomass granules and molding machines, which is applied in the direction of material molding presses, presses, manufacturing tools, etc., which can solve the problems of short continuous production time, high use cost, and short service life of equipment, and achieve continuous working time. and work efficiency, start smoothly and softly, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

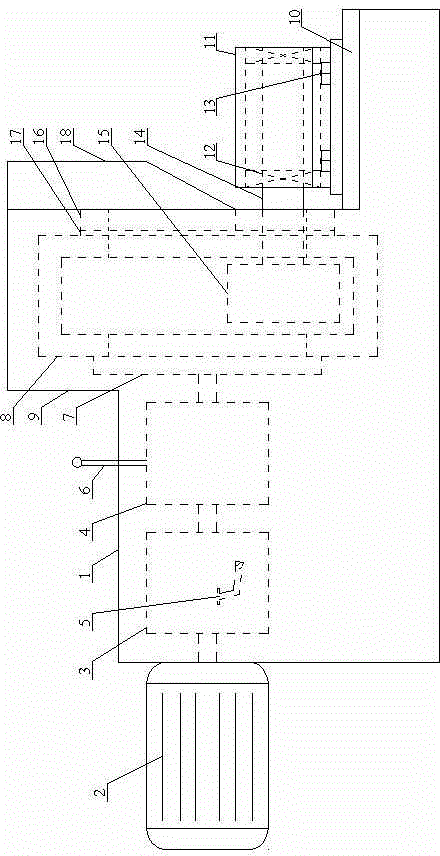

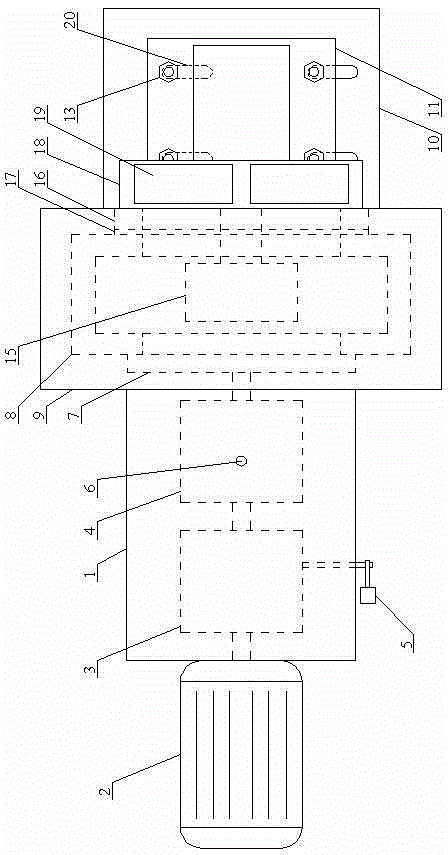

[0027] Example 1, such as Figure 1-Figure 5 The biomass pellet and rod-shaped fuel molding machine shown includes a casing 1, a motor 2 at the left end of the casing 1, and a transmission 4 and a clutch 3 connected to the motor 2 in the casing 1. The transmission 4 is provided with a gear lever 6, A clutch pedal 5 is provided on the clutch 3, and the clutch pedal is located outside the casing 1.

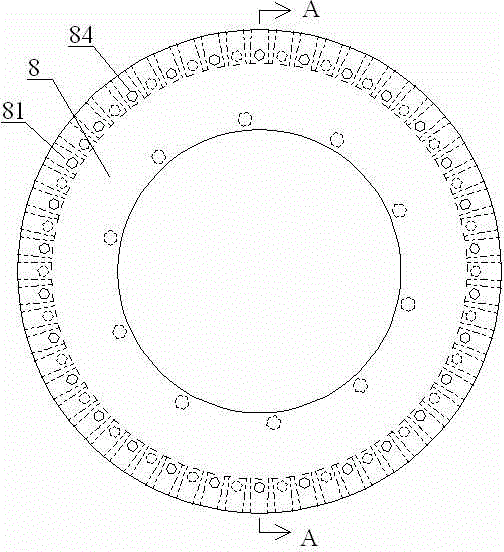

[0028] At the output end of the transmission 4, a molding die plate 8 is installed through the fixed plate 7, and a material storage tank 85 is arranged inside the forming die plate 8, and two circles of forming holes communicating with the material storage tank 85 are evenly distributed on the circumference of the forming die plate 8 81, the two rings of forming holes 81 are arranged alternately, and the two sides of the forming die plate 8 are respectively provided with pressing wires 84 corresponding to the two rings of forming holes 81. This type of forming die plate 8 is especi...

Embodiment 2

[0033] Example 2, such as Image 6 As shown, the difference from Embodiment 1 is that in the present invention, the forming hole 81 can also be formed by an inner cylindrical forming section 82 and an outer conical discharge section 83, and the size of the discharge section 83 is larger than the forming section The size of 82, the forming hole 81 is set in sections, the forming section 82 and the discharge section 83 can greatly improve the structural strength of the forming hole 81 and the forming die plate 8, prolong the service life of the forming die plate 8, reduce production costs, and improve equipment continuity. Working hours and productivity.

[0034] The invention is not only suitable for the production of biomass pellets and bar-shaped materials, but also suitable for the processing and molding of feed, and has a wide application range.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com