Electrical power steering drive assembly

A technology of electronic power steering and drive assembly, applied in electric steering mechanism, power steering mechanism, steering mechanism, etc., can solve problems such as affecting normal use, system structural damage, complex structure, etc., achieving reasonable structure, simplified structure, Well-planned effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

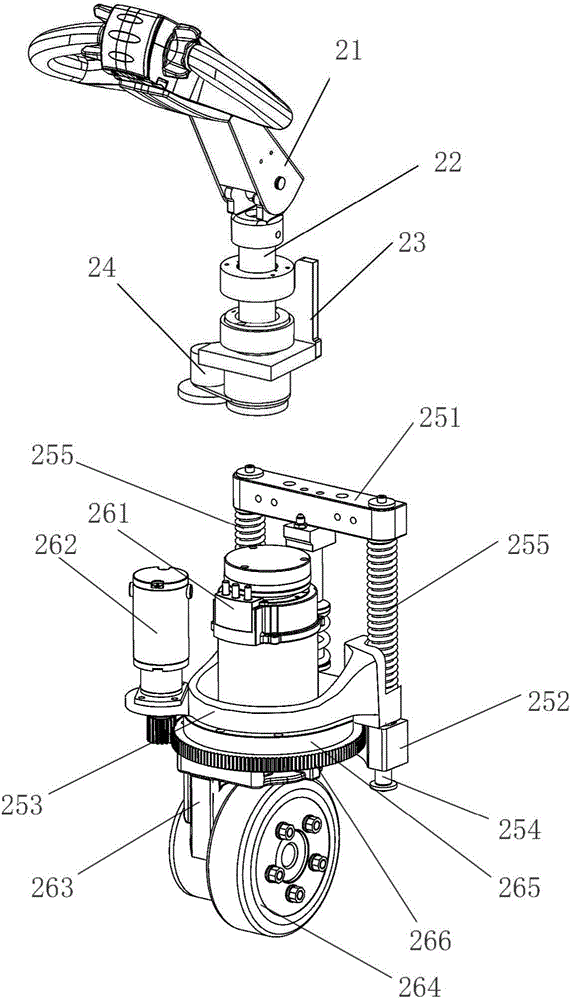

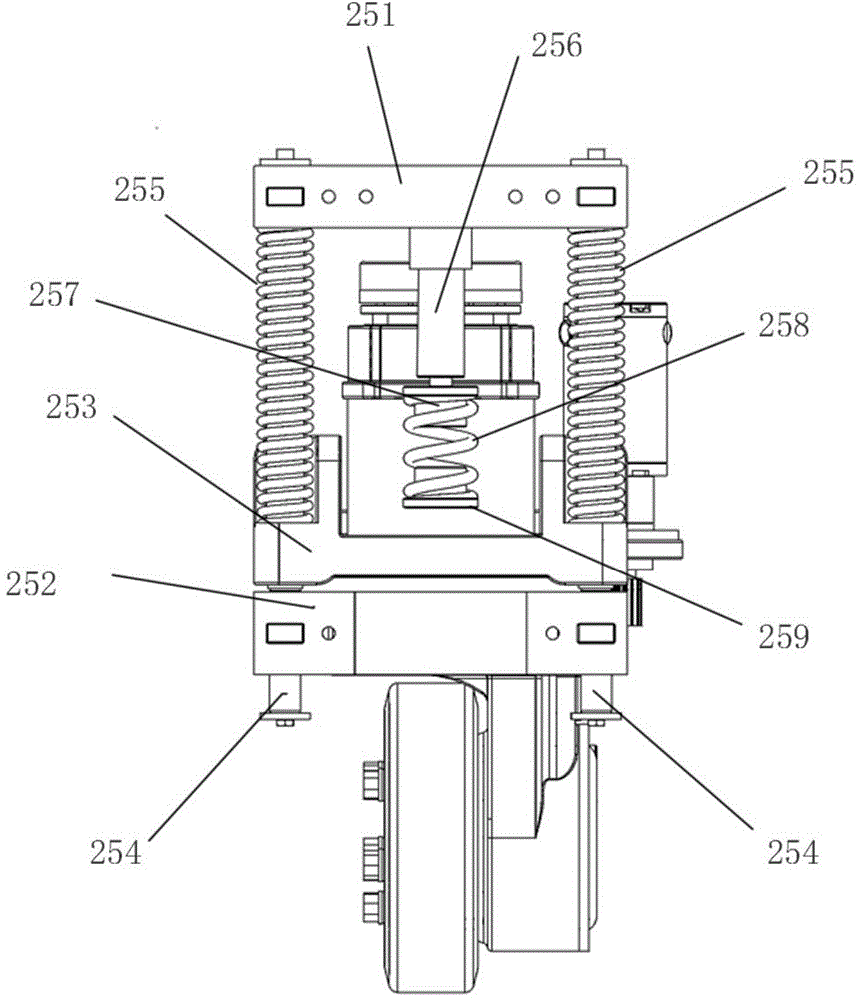

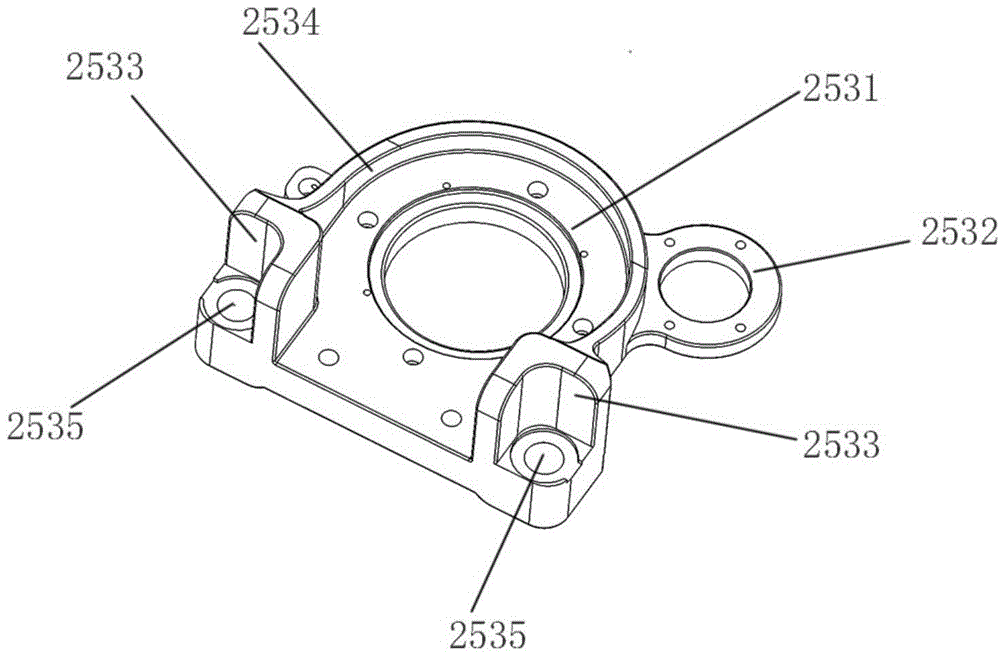

[0014] see Figure 1-3 , the electronic power steering drive assembly of this embodiment includes a vehicle frame, a handle 21, a handle shaft 22, a rotating shaft lock plate 23, an angle sensor 24, a control module, a shock absorber bracket 25, a driving drive motor 261, a steering drive motor 262, a deceleration Casing 263, drive wheel 264, wherein, one end of handle 21 is hinged on the upper end of handle shaft 22, and the vertical setting of handle shaft 22 is installed on the vehicle frame, and the lower end of handle shaft 22 drives the angle sensor 24 through the gear. The movable parts rotate to identify the rotation angle of the handle shaft 22. The control module is connected to the angle sensor 24, the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com