Coal moving resistance device of main inclined shaft loading point

A main inclined shaft and loading point technology, which is used in cleaning devices, transportation and packaging, conveyor objects, etc., can solve problems such as normal production and main inclined shaft paralysis, achieve reasonable and reliable structural design, improve transportation capacity, and improve processing. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

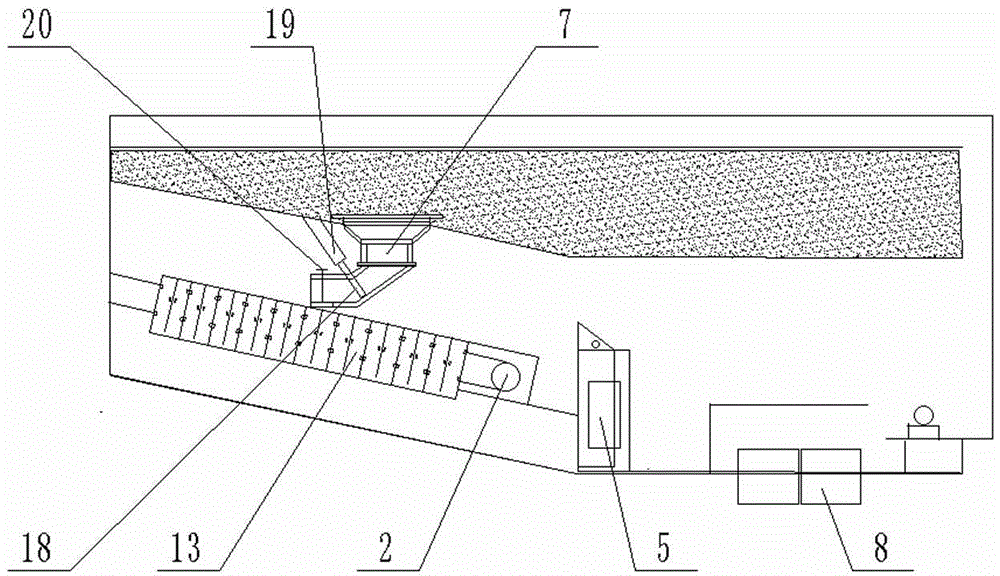

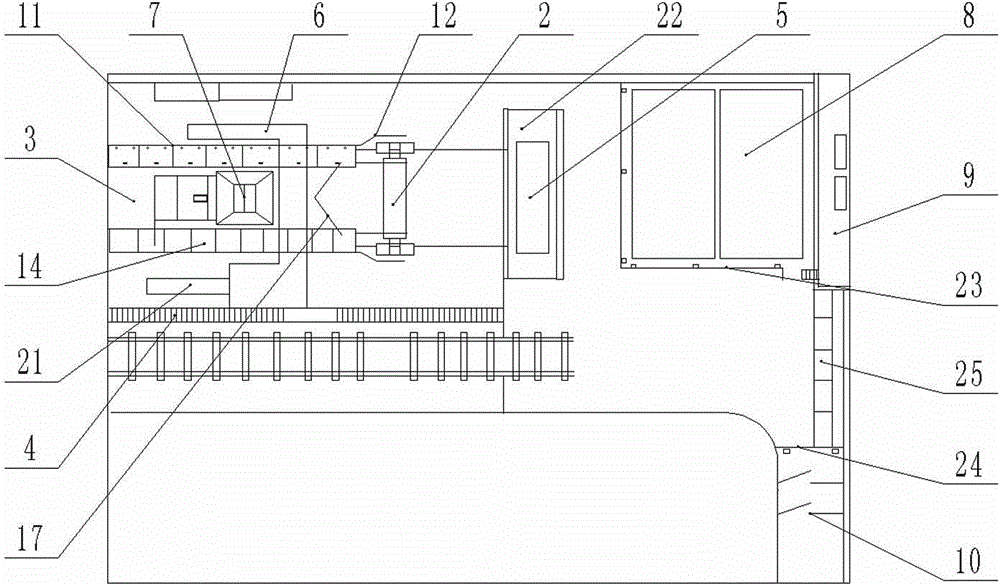

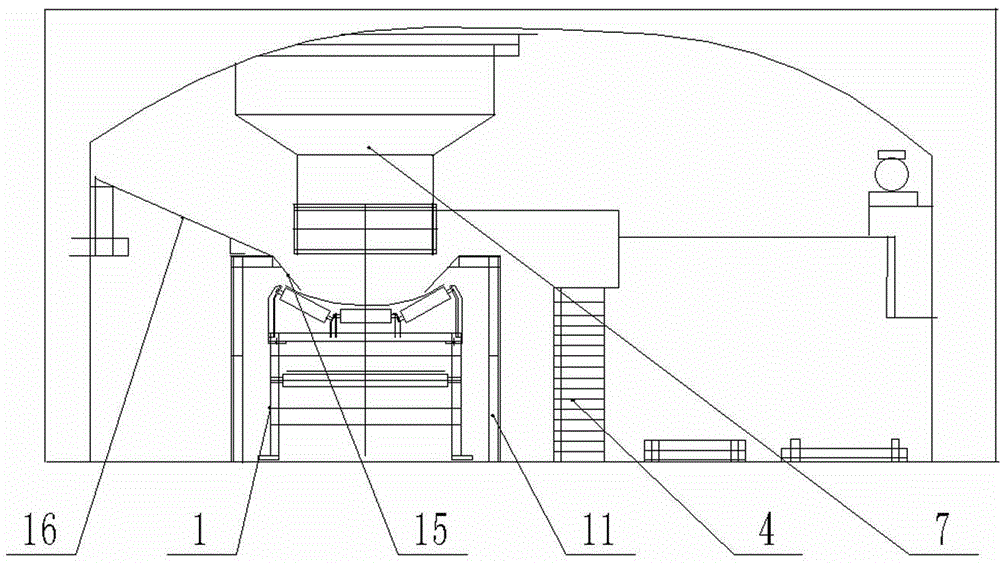

[0012] The anti-coal device at the loading point of the main inclined shaft includes a belt frame 1, on which a belt 3 bypassing the tail drum 2 is arranged, a pedestrian ladder 4 is arranged on the right side of the belt frame 1, and a matching belt is arranged behind the belt frame 1. There is an operation platform 6 above the weight 5 and the belt rack 1, a coal feeder 7 is arranged on the operation platform 6, a water tank 8 and an operation platform I9 are arranged behind the counterweight 5, and a damper is arranged on the right side of the operation platform I9 10. The left and right sides of the belt rack 1 are provided with a frame-type coal retaining frame 11, and the rear end of the coal retaining frame 11 is provided with a coal retaining cover 12 located on the left and right sides of the tail drum 2, and the outer ends of the two coal retaining frames 11 are provided with The side door panels 13, the upper end surfaces of the two coal retaining frames 11 are provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com