Rotary lifting device for repairing coke oven door

A technology of landing gear and furnace door, which is applied to the heating of coke ovens, doors/closures of coke ovens, coke ovens, etc. Overcome the effects of difficult installation and debugging, easy observation and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

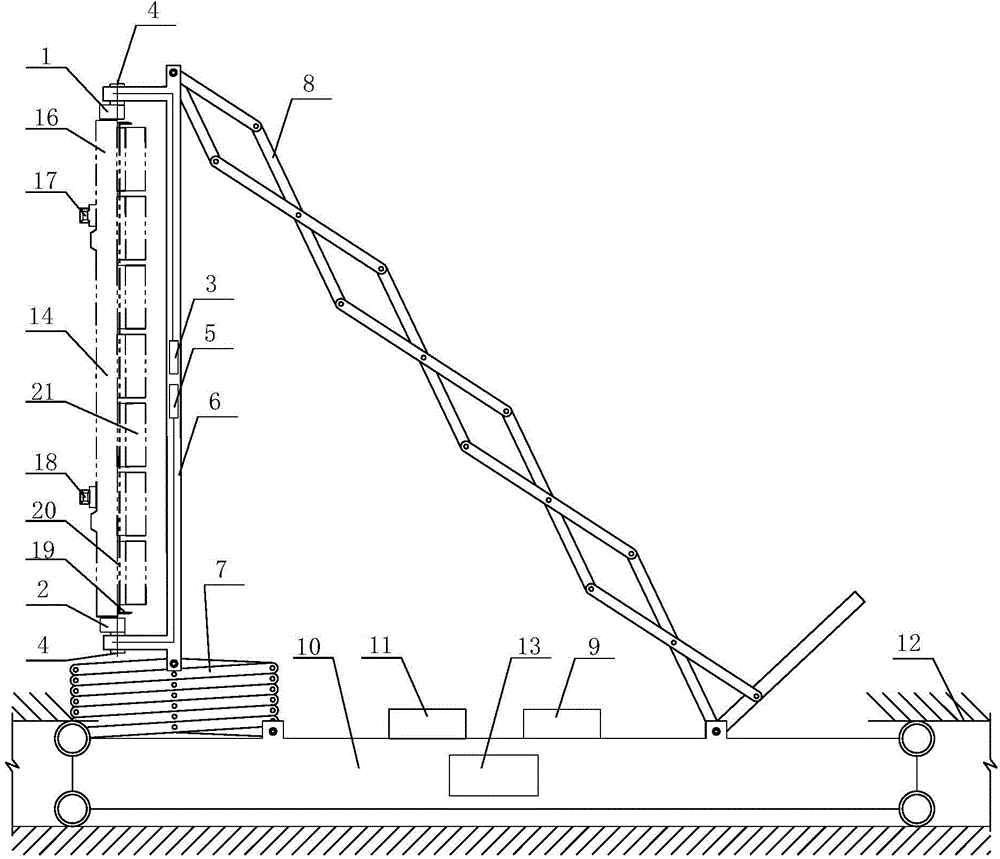

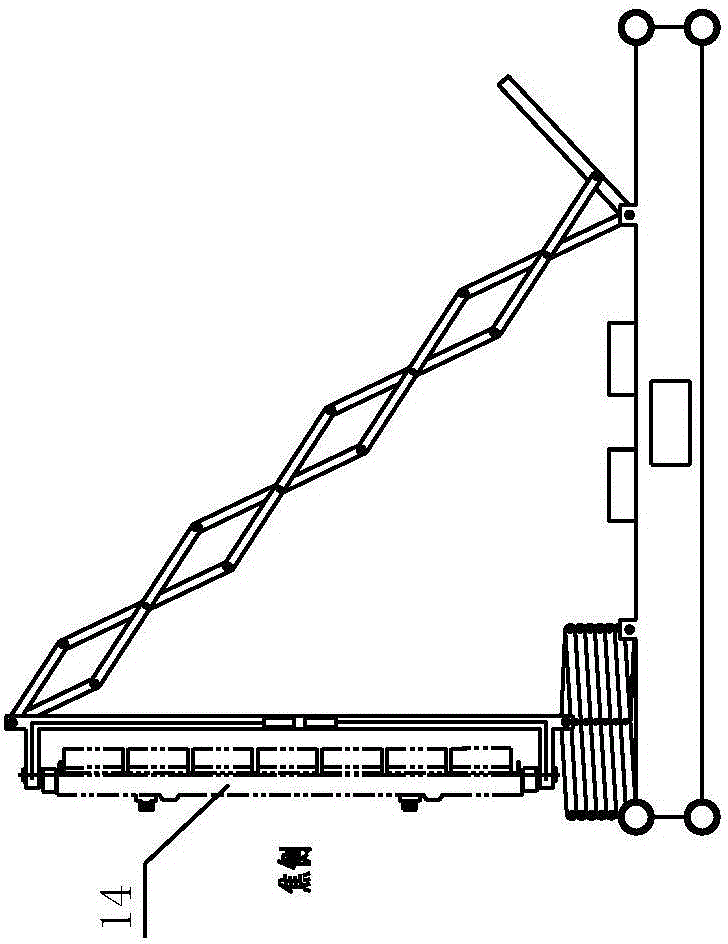

[0026] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

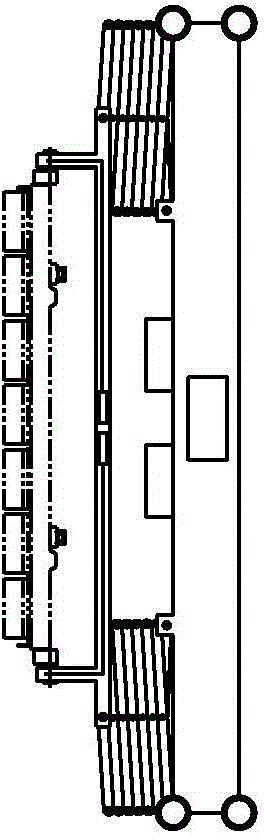

[0027] See figure 1 , is a structural schematic diagram of the present invention, a rotary lifting device for repairing the coke oven door of the present invention, including a main frame 6, a docking mechanism, a rotating mechanism, a lifting mechanism, a running mechanism and a control system 13, the docking mechanism and the rotating mechanism Installed on the main frame 6, the main frame 6 is connected with the running mechanism through the lifting mechanism, the running mechanism can move along the ground guide rail, and the control system 13 controls each mechanism to complete the butt clamping, rotation, lifting and lifting of the coke oven door 16 And walking trolley 10 walking actions.

[0028] The main frame 6 is a unilateral frame structure.

[0029] The docking mechanism is composed of an upper docking joint 1, a lower docking joint ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com