Fe-Cr-B system corrosion-resistant block amorphous alloy and preparation method thereof

An amorphous alloy, fe-cr-b technology, which is applied in the field of amorphous alloys to achieve excellent mechanical properties, corrosion resistance and improved corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be specifically introduced from three aspects of composition design, alloy preparation and performance testing.

[0039] 1. Composition design

[0040] Design Fe of different compositions a Cr b Mo c B d m e R f x g Alloy, its composition characteristics are: M is one or more of Mn, Co, Ni; R is one or more of Ti, Zr, Nb, Hf, Ta, W; X is Si, P one or more. Among them, 20<a≤78, 5≤b≤45, 0≤c≤20, 6≤d≤30, 0≤e≤40, 2≤f≤15, 0≤g≤10, a+b+c+ d+e+f+g=100.

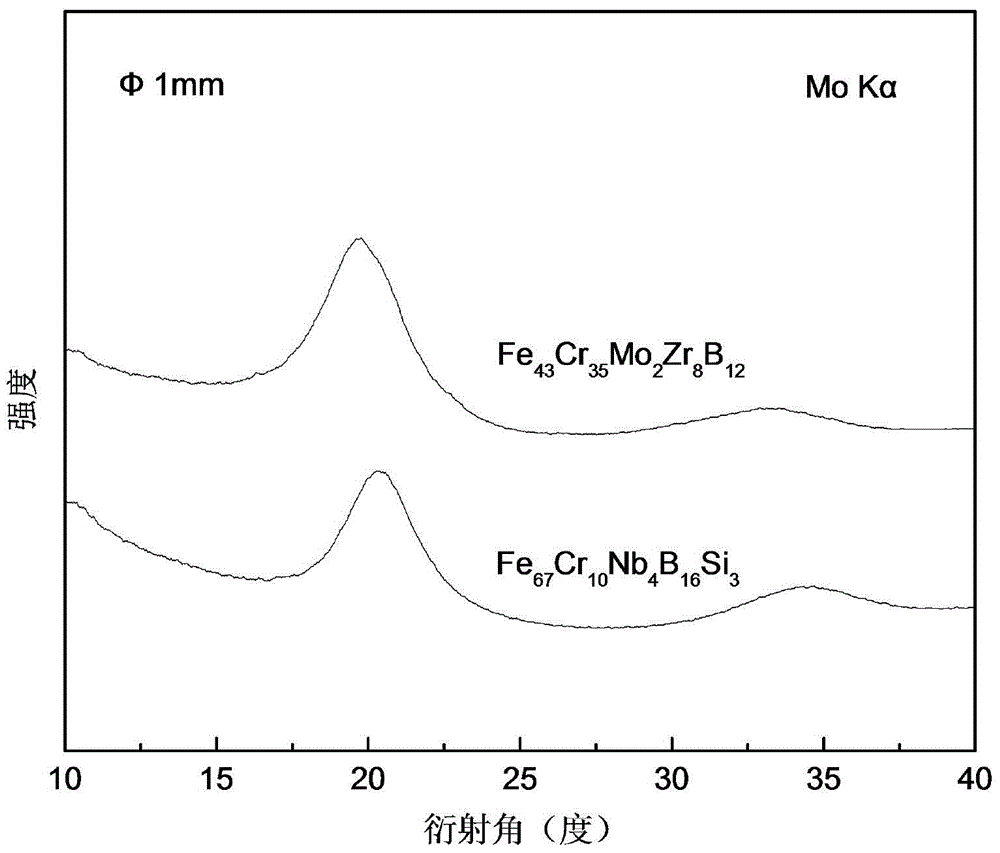

[0041] Fe and Cr are the basic components of the alloy system, and B elements are indispensable amorphous forming elements; Zr and Nb are large atoms with large negative heat of mixing with the main components, which can further improve the amorphous forming ability of the alloy, and Ti , Hf, Ta, W can be partially replaced as neighbor elements. Design composition Fe a Cr b B d R f .

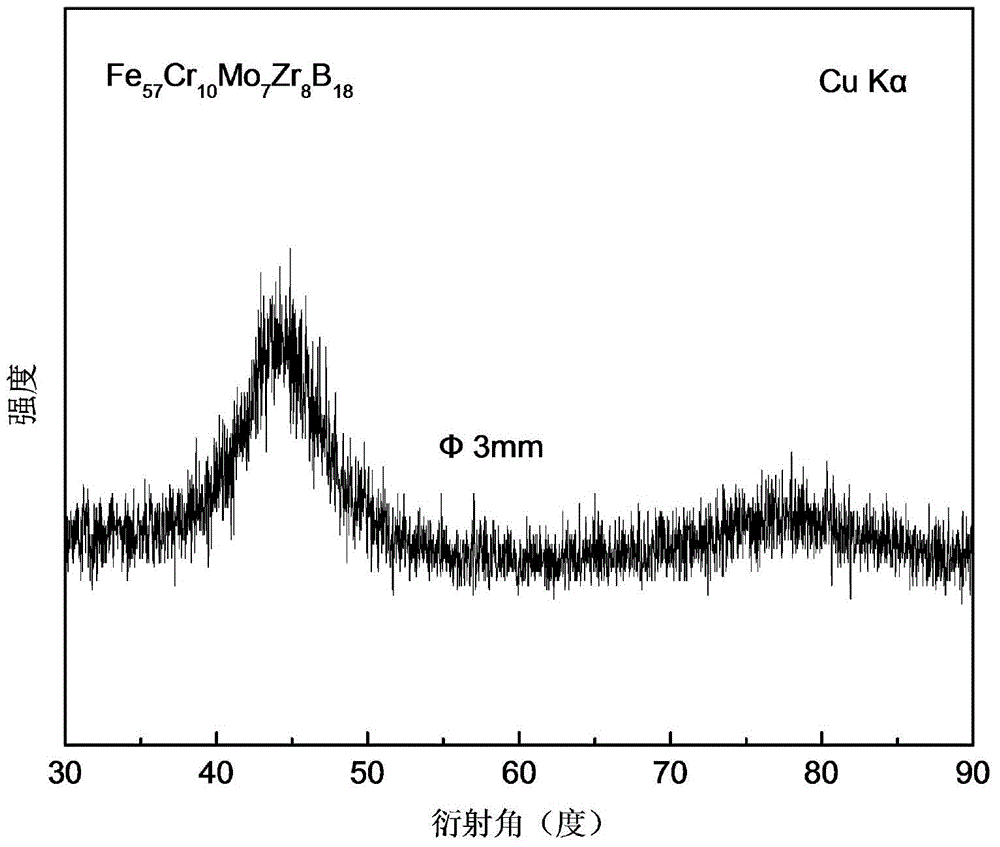

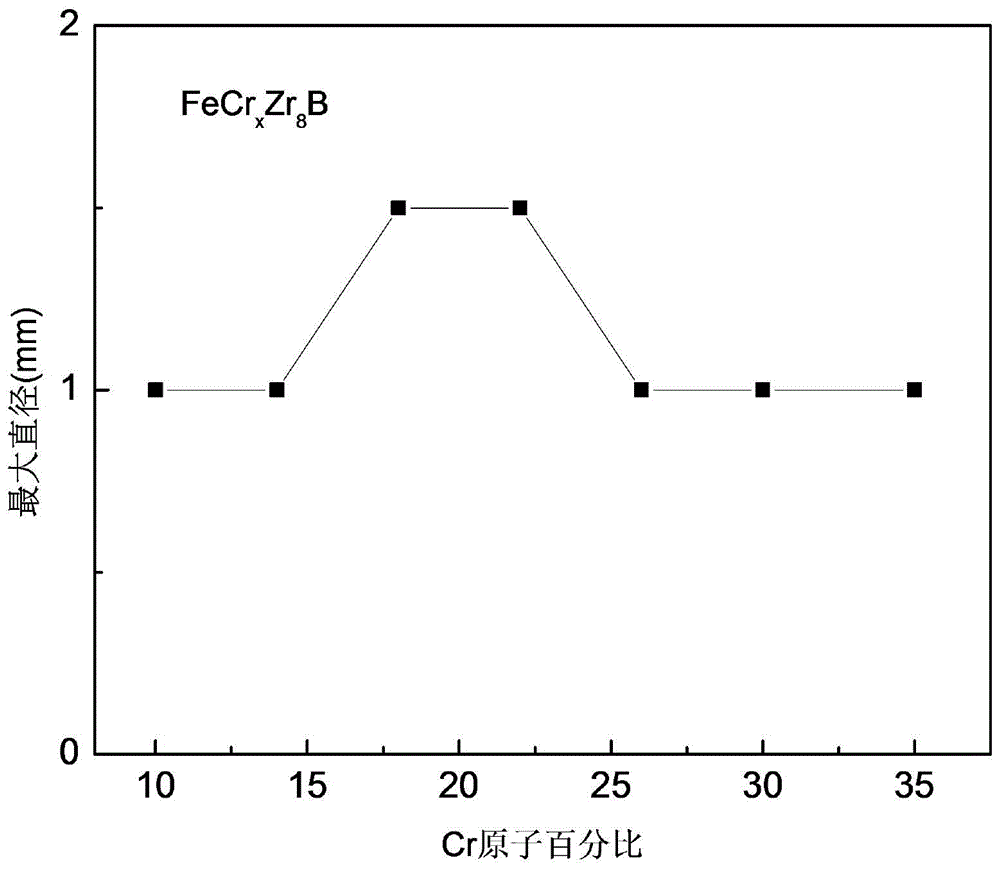

[0042] As a congener element of Cr, the addition of Mo can further improve the amorphous forming abili...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com