Light high-strength cable bridge and production process thereof

A technology of cable bridge and production process, which is applied in the direction of pipeline supports, electrical components, pipes/pipe joints/pipe fittings, etc., which can solve problems such as increased prices, low precision of bridges, and increased labor costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

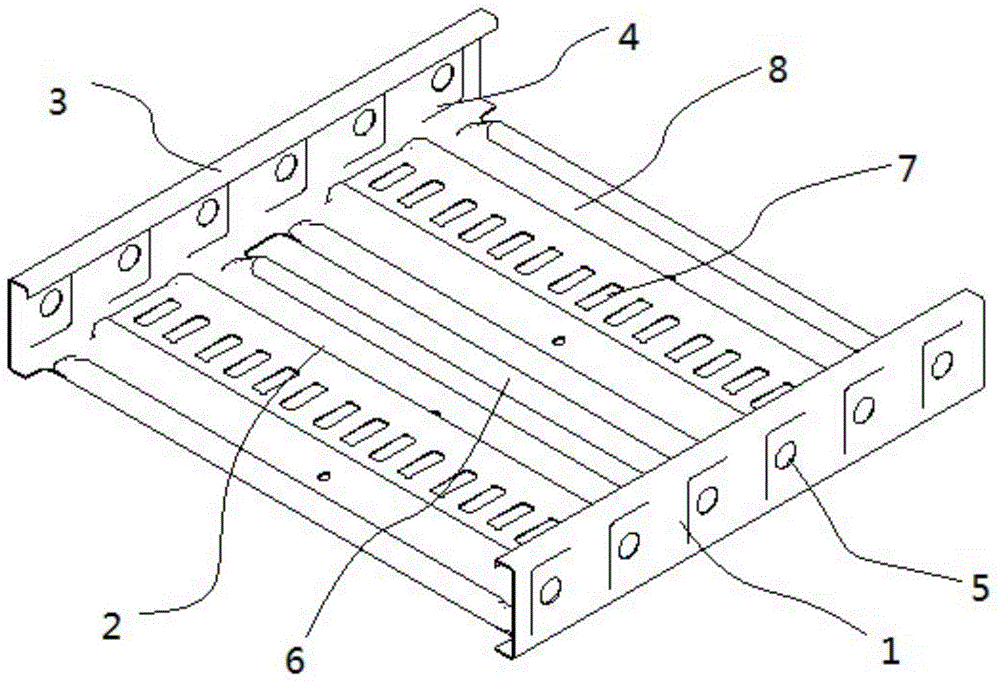

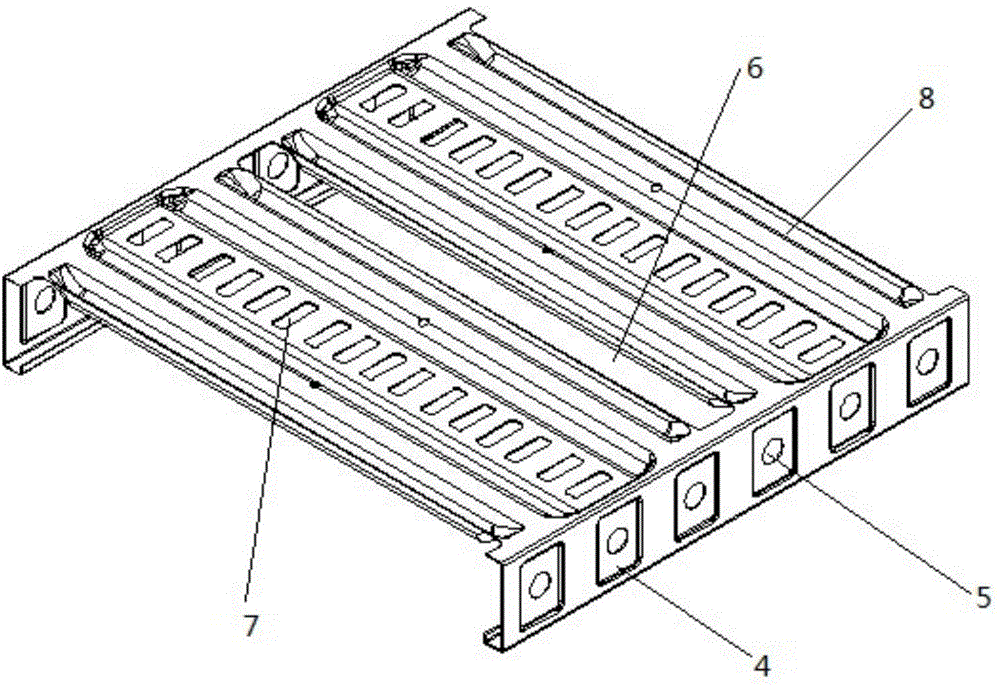

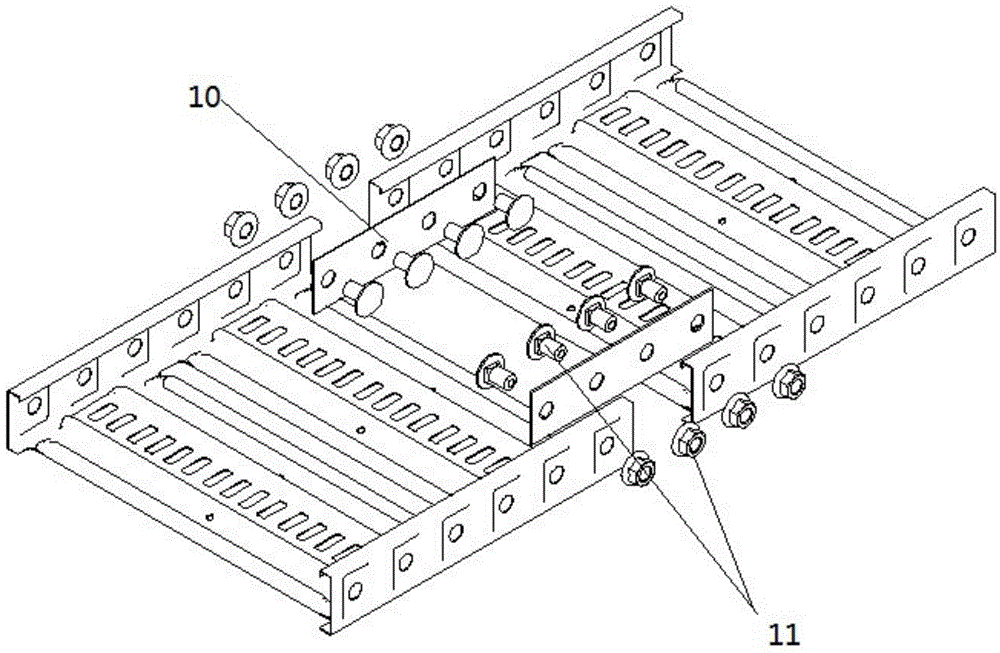

Embodiment 1

[0027] A lightweight and high-strength cable tray provided in this embodiment has a structure such as Figure 1 to Figure 3 As shown, it is formed by connecting multiple bridge units, and the adjacent bridge units are connected and fastened by connecting plates 10 and connecting bolts and nuts 11. Each bridge unit is composed of two side plates 1 and a bottom plate 2. The adjacent bridge units Rectangular ventilation holes 6 are provided between the bottom plates of the unit, and the upper ends of the two side plates are provided with inward flanges 3, and the two sides of the bottom plate perpendicular to the side plates protrude upwards to form two strip-shaped bottom plate side reinforcements Rib 8, the middle part of the bottom plate is raised upwards to form a reinforced surface in the middle of the bottom plate, and the two sides of the reinforced surface in the middle of the bottom plate are raised upwards to form two strip-shaped ribs in the middle of the bottom plate. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com