Automatic sealing rotating stabilized deep sediment sampler

An automatic sealing, sampler technology, applied in the sampling device and other directions, can solve the problems of sample damage, large sample interference, limited length of the control rod, etc., and achieve the effect of complete shape and small interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

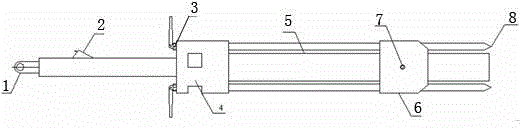

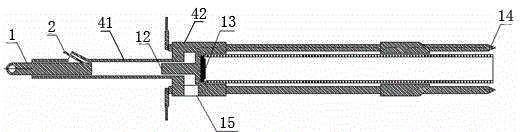

[0039] Below in conjunction with accompanying drawing, further illustrate structure and working method of the present invention:

[0040] The self-closing rotary stable deep sediment sampler includes a sampler main body, an automatic bottom-sealing device and a sampling tube. The main part of the sampler is the structural frame of the sampler and the installation body of each component of the sampler.

[0041] see figure 1 and image 3 , The main part of the sampler includes a seat body 4, a rope connecting rod 1, an automatic closing hook 2, a connecting screw 3, a support rod 8 and a sampling tube sealing valve 12, etc.

[0042] The seat body 4 is cylindrical and is made of a large cylinder and a small cylinder. The large cylinder section 42 is used as a joint for installing the sampling tube 5, and the plexiglass sampling tube can be easily disassembled. The large cylinder section and the small cylinder section are detachable structures, connected and fixed by conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com