Artificial core containing controllable and movable fluid, and manufacturing method of artificial core

A technology of artificial core and manufacturing method, which is applied in the preparation of test samples, etc., can solve the problems of poor distribution accuracy of movable fluid and single pore structure distribution of artificial core, and achieve simple manufacturing procedures, controllable distribution of movable fluid, The effect of good technical support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

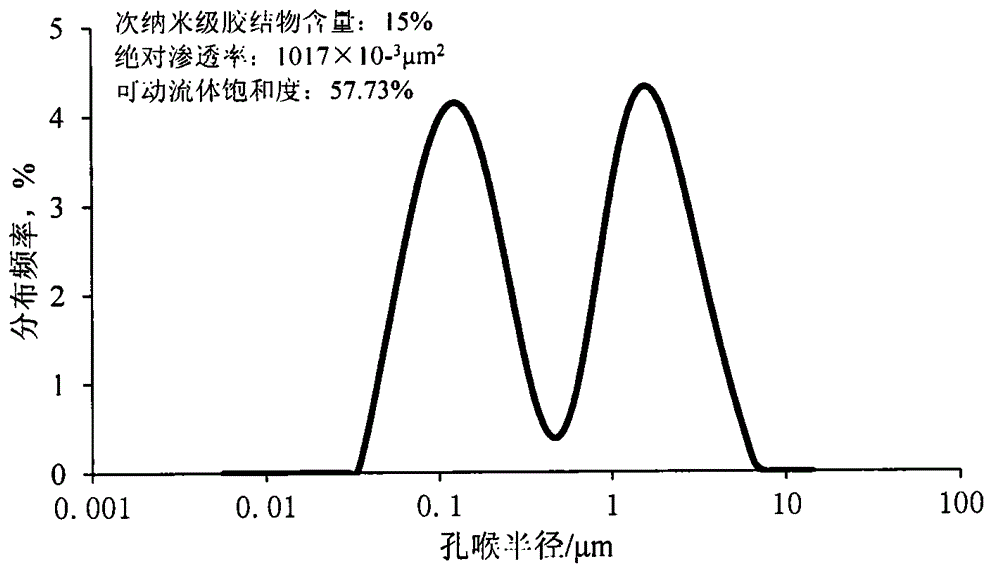

[0025] Mix 80g of quartz sand, 5g of epoxy resin cement, and 15g of sub-nanometer powder cement and stir thoroughly. Among them, the ratio of different mesh numbers of quartz sand: 2.11% for 200 mesh or more, 8.42% for 100-200 mesh, 15.79% for 60-100 mesh, 36.84% for 40-60 mesh, 31.58% for 30-40 mesh, 31.58% for 20-40 mesh 30 mesh is 5.26%; the mass percent of each component in the subnano-scale powdery cement is: tricalcium silicate is 20%, dicalcium silicate is 30%, tricalcium aluminate is 25%, crystalline calcium sulfate is 25%. Wipe the inner wall of the square carbon steel mold with acetone repeatedly to fully dilute the residual cement on the inner wall to make it as clean and pollution-free as possible, then divide the fully stirred mixture into three parts and pour it into the inner cavity of the mold. For each portion, the mixture was manually compacted with a compactor to ensure uniform particle distribution during subsequent compaction. Place the mold filled with ...

Embodiment 2

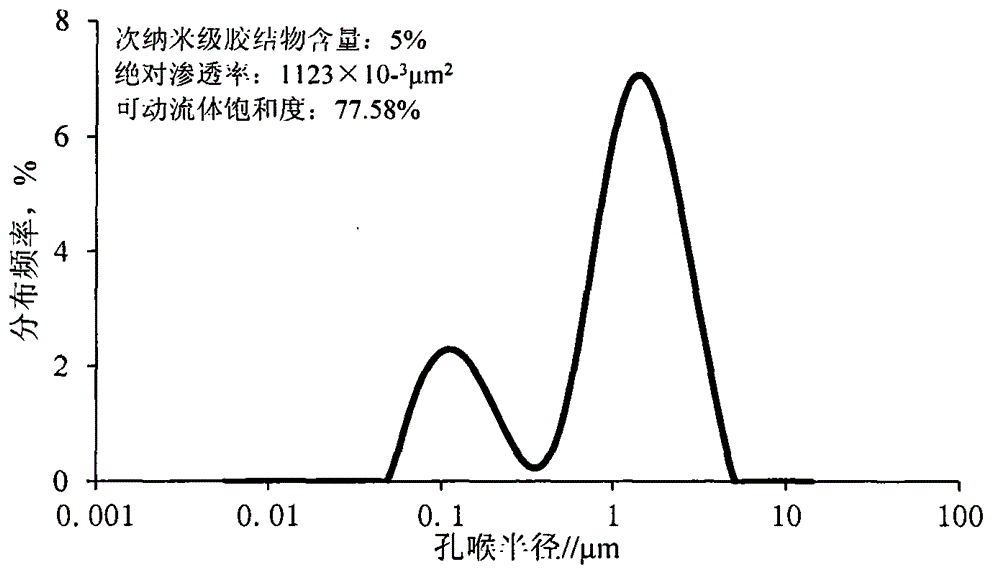

[0027] Mix 85g of quartz sand, 10g of epoxy resin cement, and 5g of subnano-scale powder-like cement and stir thoroughly. The ratio of different meshes of quartz sand is: 11.89% for 200 mesh or more, 7.58 for 100-200 mesh %, 60-100 mesh is 14.21%, 40-60 mesh is 33.16%, 30-40 mesh is 28.42%, 20-30 mesh is 4.74%; the mass percent of each component in subnano-scale powdery cement is : Tricalcium silicate is 20%, dicalcium silicate is 30%, tricalcium aluminate is 25%, crystalline calcium sulfate is 25%. Wipe the inner wall of the square carbon steel mold repeatedly with acetone to fully dilute the residual cement on the inner wall to make it as clean and pollution-free as possible. For each portion, the mixture was manually compacted with a compactor to ensure uniform particle distribution during subsequent compaction. Place the mold filled with the mixture on the central axis of the press platform, and at the same time apply a pressure of 10 MPa to the pressure column for 30 min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com